Small modulus straight bevel gear CNC gear planer with cutter and adjustment device

A technology of straight bevel gear and adjustment device, which is applied to gear tooth manufacturing device, gear cutting machine, belt/chain/gear, etc., can solve the problem that the small module straight bevel gear planer cannot be used, and the knife action is not agile enough. , reliability, inability to adjust the amount of cutting tools, etc., to achieve the effect of small occupied space, compact structure, and satisfying processing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0023] It should be noted that, unless otherwise clearly stipulated and limited, the terms "first", "second" and the like do not represent sequential installation, nor do they represent the importance of the described components.

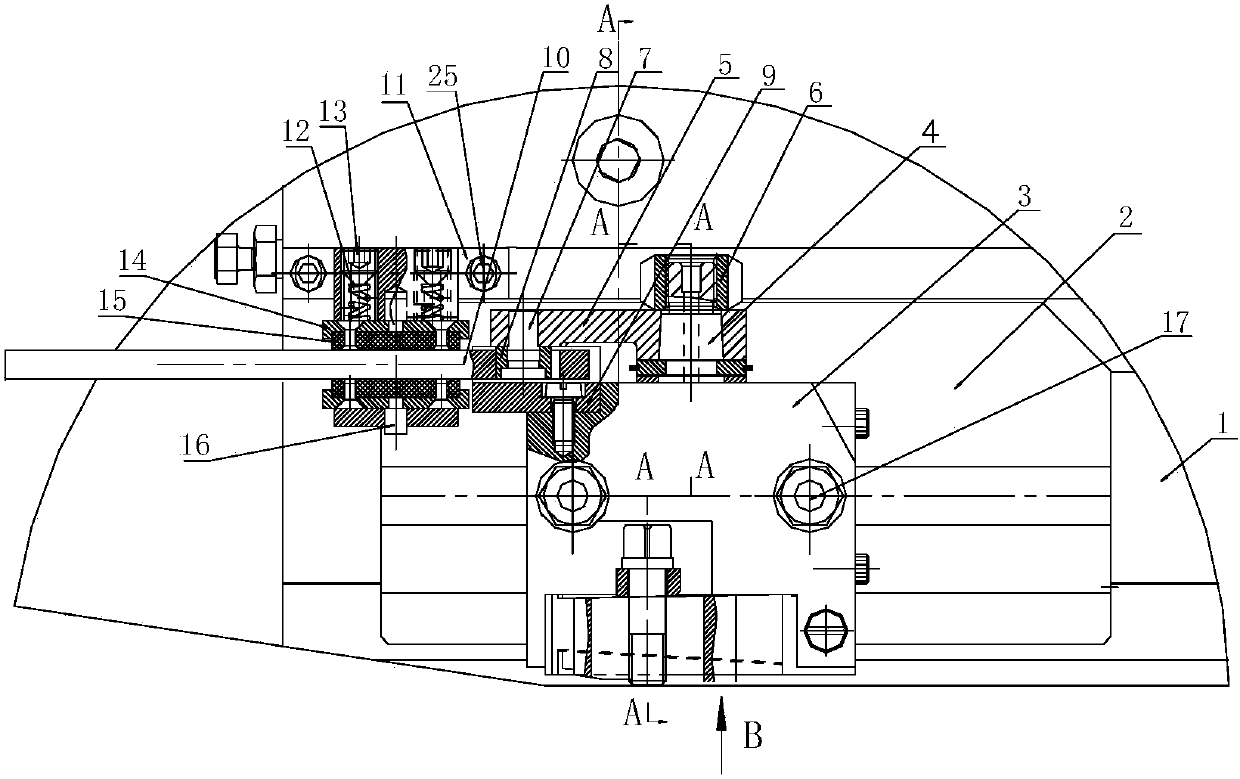

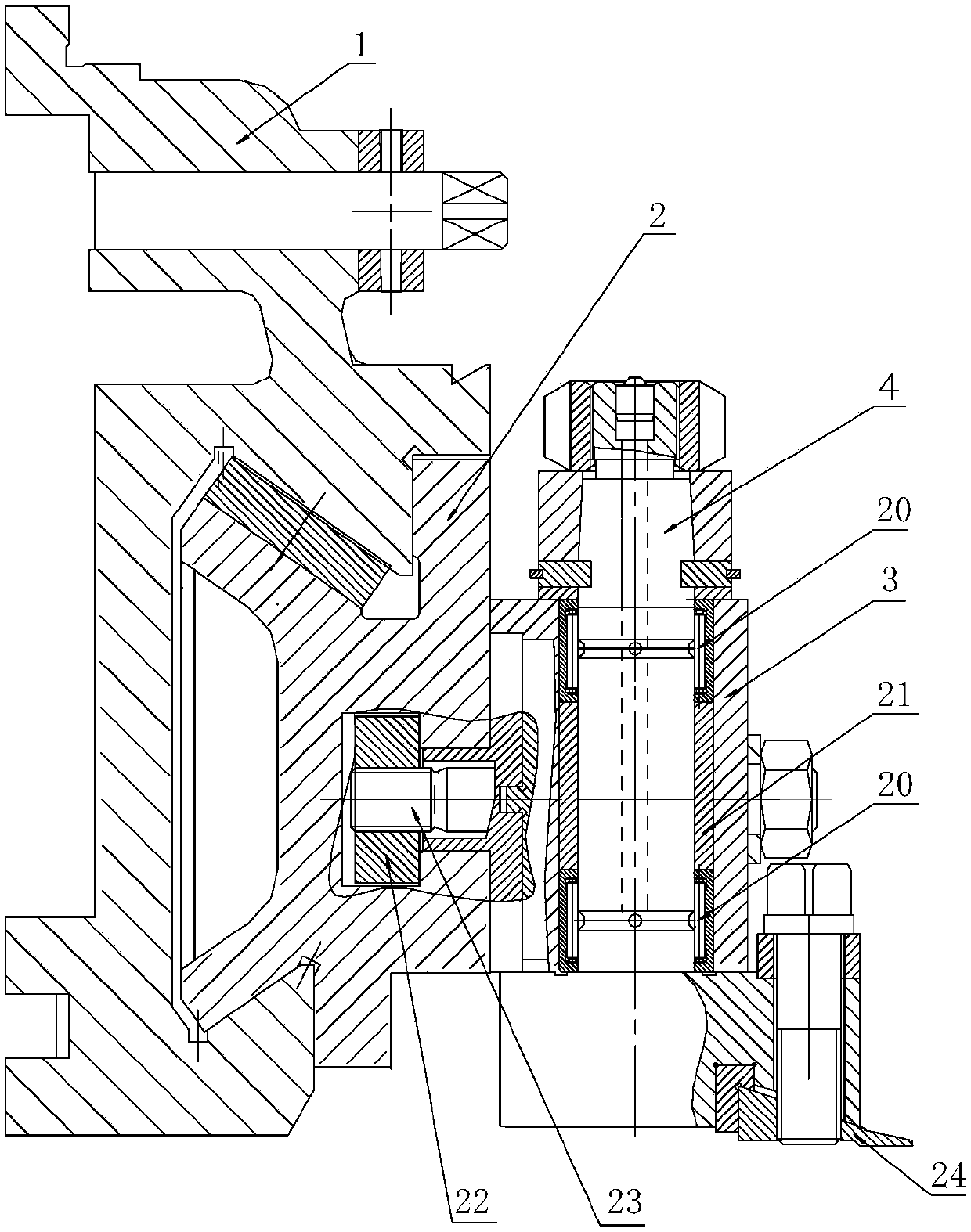

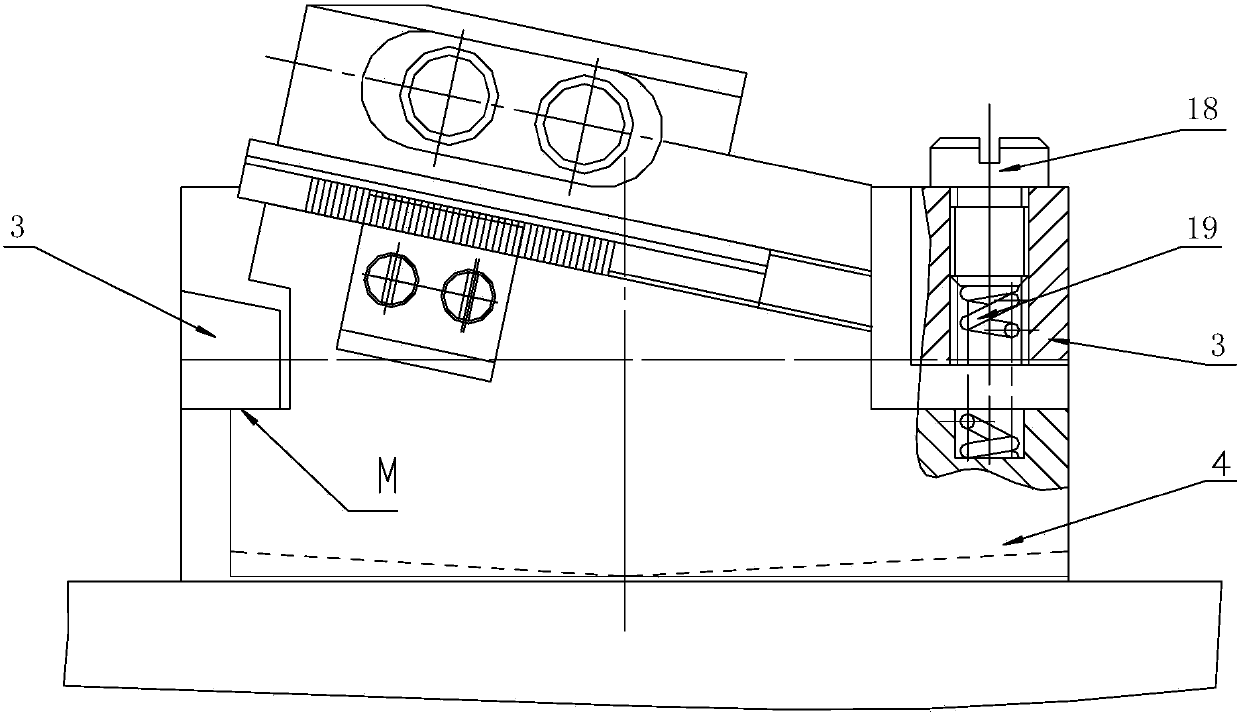

[0024] see Figure 1-Figure 5 , small modulus straight bevel gear CNC gear cutter and adjustment device, including the tool rest seat 1 symmetrically installed on the drum of the cradle, the ram 2 that reciprocates on the guide rail of the tool rest seat, and the symmetrical The installed ram 2 is equipped with a tool seat bracket 3 and a tool seat 4, and the tool seat 1 is connected to the splint seat 11 by a hexagon socket head screw 25, and a symmetrically arranged splint 14 is fixed on the splint seat 11 by a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com