Fixed abrasive grinding and chemical-mechanical polishing method for nickel-base alloy

A fixed abrasive, chemical-mechanical technology, used in polishing compositions containing abrasives, grinding machine tools, grinding devices, etc., can solve the problems of surface corrosion of nickel-based alloys, difficult to guarantee surface shape accuracy, harsh and strict process requirements, etc.

Inactive Publication Date: 2016-11-09

CHANGZHOU INST OF DALIAN UNIV OF TECH

View PDF8 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The traditional nickel-based alloy processing method mainly uses free abrasive grinding, and uses strong acid, strong alkali and toxic chemical reagents as chemical mechanical polishing fluid. Free abrasive grinding is difficult to guarantee the surface shape accuracy of the workpiece, while strong acid, strong Alkali and toxic chemical reagents corrode the surface of nickel-based alloys very seriously, and the process requirements are very harsh and strict, and strong acids, strong alkalis and toxic chemical reagents have great potential hazards to operators and the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] The specific implementation manner of the present invention will be described in detail below in conjunction with the technical solutions.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Login to View More

Abstract

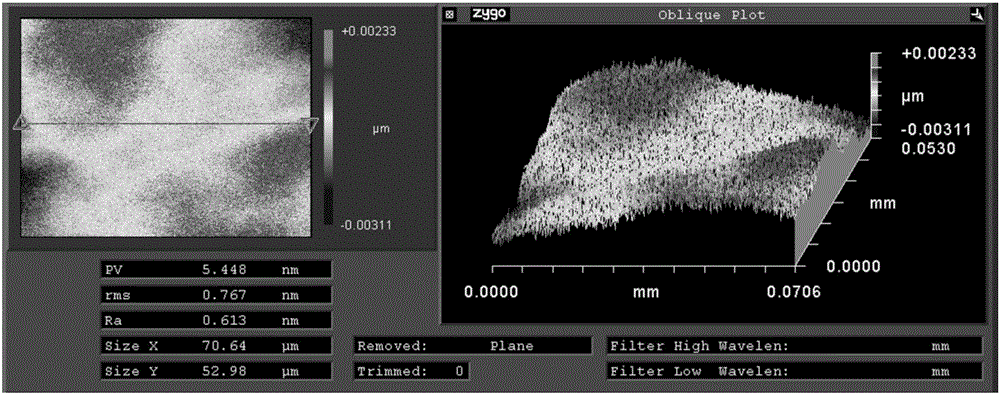

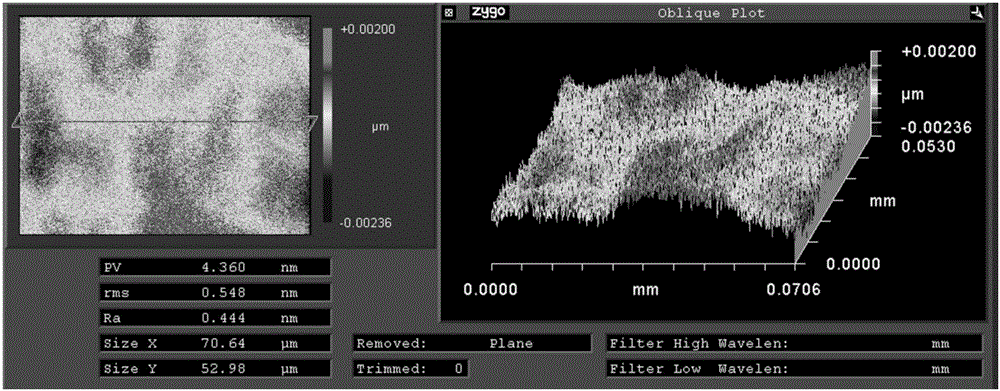

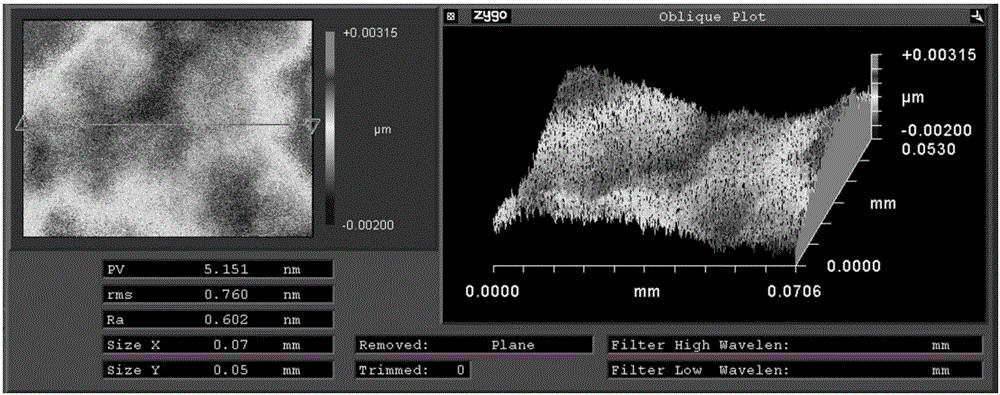

The invention discloses a fixed abrasive grinding and chemical-mechanical polishing method for nickel-base alloy, and belongs to the technical field of ultra-precision machining of alloy. Silicon carbide waterproof abrasive paper serves as a grinding tool, and grinding liquid is deionized water. A polishing pad is fuzzy damping cloth, the polishing pressure is 40-60 kPa, the polishing time is 5-12 min, and the rotation speed of a polishing plate and the rotation speed of a workpiece are 61 rpm and 59 rpm correspondingly. Chemical-mechanical polishing is divided into a rough polishing stage and a finish polishing stage. During rough polishing, polishing abrasive particles are aluminum oxide, the size is 60-100 nm, and polishing liquid is deionized water. During finish polishing, polishing liquid contains silica sol, malic acid, hydrogen peroxide and deionized water, and the pH value of the polishing liquid is 3-4. After chemical-mechanical polishing, the surface roughness Ra of the nickel-base alloy is 0.45 nm, and the PV value is 4.4 nm. The ultra-precision polishing method for the nickel-base alloy is realized, the silicon carbide waterproof abrasive paper serves as the fixed abrasive grinding tool, the silica sol, the malic acid, the hydrogen peroxide and the deionized water serve as the polishing liquid, and ultra-precision polishing for the nickel-base alloy is realized.

Description

technical field [0001] The invention belongs to the technical field of ultra-precision machining of alloys, and relates to an ultra-precision machining method combining alloy solidified abrasive grinding and chemical mechanical polishing, in particular to a nickel-based alloy ultra-precision polishing method. Background technique [0002] Nickel-based alloys are widely used in aviation, aerospace, nuclear power, marine, petrochemical, food, biomedical and other fields. They are alloy materials with high cost and added value. Due to their good heat resistance, wear resistance, corrosion resistance, oxidation resistance, Excellent performance such as high temperature resistance is an indispensable key component material. It becomes a reflection of the advanced level of a country's industry and is also one of the important indicators of a country's industrial advancement. With the rapid development of industry and technology, the requirements for the surface of high-performance...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B24B37/00C09G1/02

CPCB24B37/00C09G1/02

Inventor 张振宇史智丰黄思玲郭梁超王博

Owner CHANGZHOU INST OF DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com