Titanium alloy grinding and chemical mechanical polishing method

A chemical mechanical and titanium alloy technology, applied in chemical instruments and methods, grinding machine tools, grinding/polishing equipment, etc., can solve problems such as operator and environmental hazards, difficult to control motion trajectory, scratches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described in detail below in conjunction with the technical solutions.

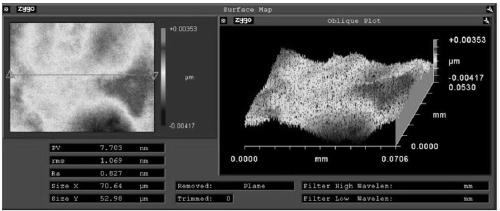

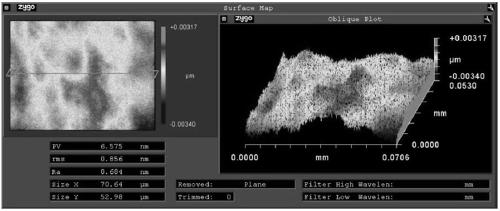

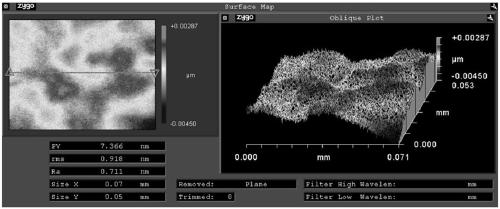

[0026] The titanium alloy sample is Ti-6Al-4V, the size is 10×10×1.5mm 3, using 502 glue to evenly bond 4 titanium alloy samples to the circumference of an aluminum alloy disk with a diameter of 150mm, and load it with a counterweight. Bond the aluminum oxide waterproof sandpaper on the stainless steel grinding disc of the grinding and polishing machine, and the alumina abrasive size selected in turn is 26μm, 16μm, 10μm, 4μm, 26 and 16μm. The grinding time of the aluminum oxide waterproof sandpaper is 5min, 10μm and 4μm The grinding time of the aluminum oxide waterproof sandpaper is 14min, 15min and 16min respectively. When replacing waterproof sandpaper with different abrasive sizes, the titanium alloy samples were cleaned with deionized water and dried with an air gun. During grinding, the rotational speeds of the grinding disc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com