Treating agent for propanil contaminated sludge and preparation method of treating agent

A technology for sludge treatment and sludge, which is applied in the field of propanil polluted sludge treatment agent and its preparation, can solve the problems of secondary soil pollution and high cost, and achieve the effects of simple treatment process, cost reduction and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

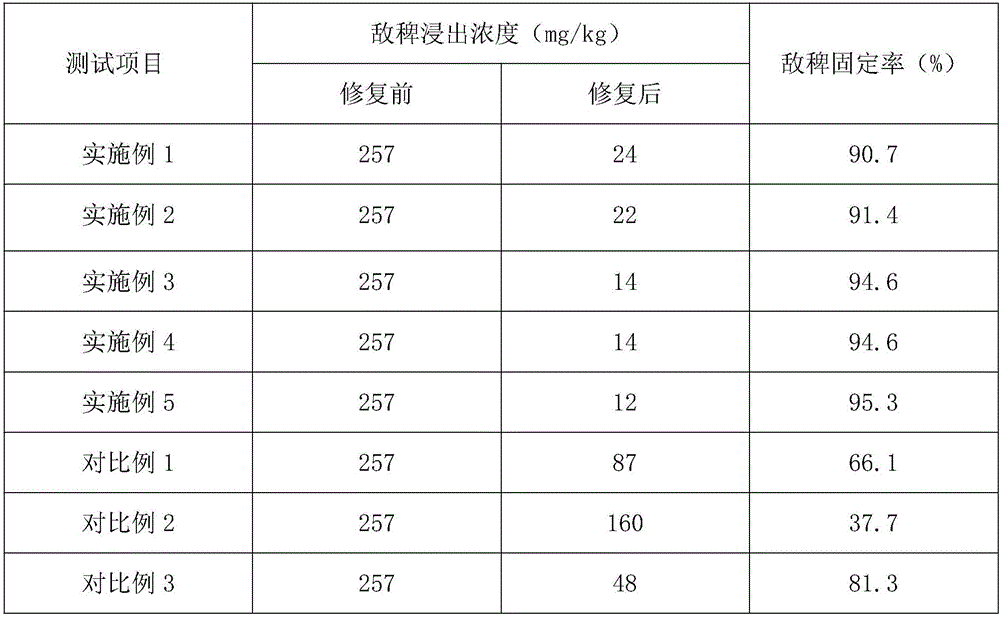

Examples

Embodiment 1

[0020] A propanil polluted sludge treatment agent, the main raw materials in parts by weight are: 20 parts of nano-modified sludge, 5 parts of bamboo charcoal, 20 parts of peptidoglycan, 10 parts of polyacrylamide, 10 parts of dihydropyridine, and carrageenan 3 parts, 0.2 parts of sodium thiosulfate, and 0.2 parts of apatite; the preparation method of the nano-modified sludge: firstly, stearic acid, thiourea, and 5-aminolevulinic acid are mixed and vacuum-filtered to obtain The mixture, and then reacting the silicon carbide, the sludge and the mixture under microwaves to obtain nano-modified sludge; the particle size of the bamboo charcoal is 600 μm; the mesh number of the sodium thiosulfate is 400 mesh.

[0021] The preparation method of described propanil polluted sludge treatment agent, concrete steps are:

[0022] (1) First, put bamboo charcoal and peptidoglycan into the nano-modified sludge, process it in a twin-shaft agitator for 30 minutes, and then extrude to make part...

Embodiment 2

[0027] A propanil polluted sludge treatment agent, the main raw materials in parts by weight are: 23 parts of nano-modified sludge, 6 parts of bamboo charcoal, 22 parts of peptidoglycan, 12 parts of polyacrylamide, 10 parts of dihydropyridine, carrageenan 3 parts, 0.2 parts of sodium thiosulfate, and 0.2 parts of apatite; the preparation method of the nano-modified sludge: firstly, stearic acid, thiourea, and 5-aminolevulinic acid are mixed and vacuum-filtered to obtain The mixture, and then reacting the silicon carbide, the sludge and the mixture under microwaves to obtain nano-modified sludge; the particle size of the bamboo charcoal is 600 μm; the mesh number of the sodium thiosulfate is 400 mesh.

[0028] The preparation method of described propanil polluted sludge treatment agent, concrete steps are:

[0029] (1) First, put bamboo charcoal and peptidoglycan into the nano-modified sludge, process it in a twin-shaft agitator for 30 minutes, and then extrude to make particle...

Embodiment 3

[0034] A propanil polluted sludge treatment agent, the main raw materials in parts by weight are: 25 parts of nano-modified sludge, 8 parts of bamboo charcoal, 25 parts of peptidoglycan, 13 parts of polyacrylamide, 13 parts of dihydropyridine, and carrageenan 4 parts, 0.3 parts of sodium thiosulfate, and 0.3 parts of apatite; the preparation method of the nano-modified sludge: firstly, stearic acid, thiourea, and 5-aminolevulinic acid are mixed and vacuum-filtered to obtain The mixture, and then reacting the silicon carbide, the sludge and the mixture under microwaves to obtain nano-modified sludge; the particle size of the bamboo charcoal is 600 μm; the mesh number of the sodium thiosulfate is 400 mesh.

[0035] The preparation method of described propanil polluted sludge treatment agent, concrete steps are:

[0036] (1) First, put bamboo charcoal and peptidoglycan into the nano-modified sludge, process it in a twin-shaft agitator for 30 minutes, and then extrude to make part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com