Prestressed duct grouting material reinforced by oxidized graphene and preparation method of prestressed duct grouting material

A technology for channel grouting and grouting material, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Volume stability, reduced bleeding rate, improved fluidity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

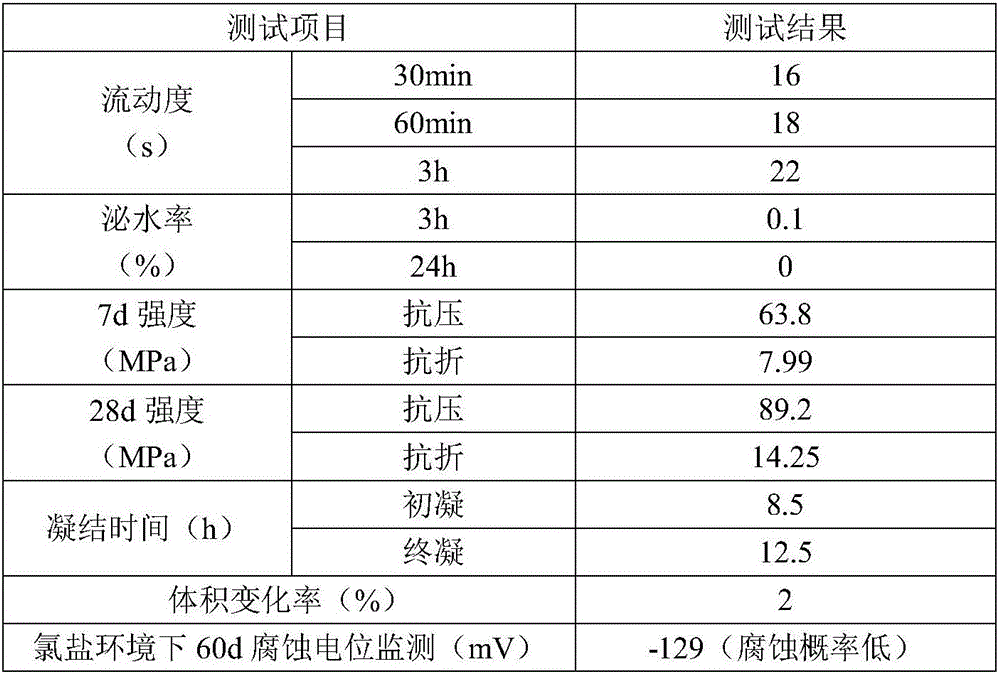

Embodiment 1

[0026] Calculated by weight components, the raw material components of the grouting material in this embodiment are as follows: 900 parts of cement, 135 parts of fly ash, 15 parts of graphene oxide, 80 parts of expansion agent, 12 parts of high-efficiency water reducer, 42 parts of rust inhibitor parts, 340 parts of water.

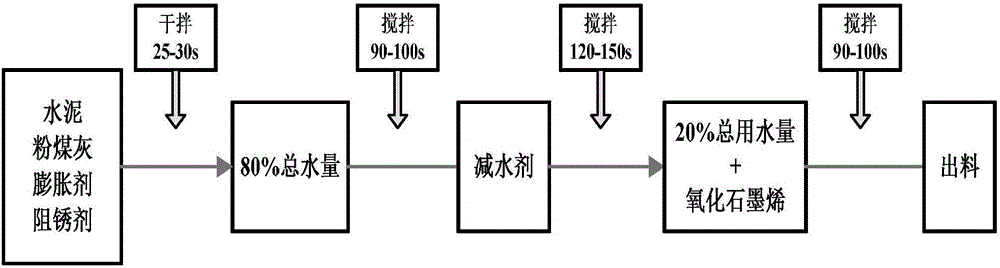

[0027] The preparation steps are as follows: Weigh each raw material according to the proportion of the formula, first dry mix cement, fly ash, expansion agent and rust inhibitor in the mixer for 25-30 seconds, then pour 80% of the total water consumption of the formula and stir for 90 seconds -100s, then pour the water reducing agent into the mixer and stir with the slurry for 120-150s, and finally mix the graphene oxide and the remaining 20% water in the container, stir evenly and pour the mixture into the mixer with the slurry Stirring is continued for 90-100s, and the graphene oxide reinforced prestressed hole grouting material is obtained. The tech...

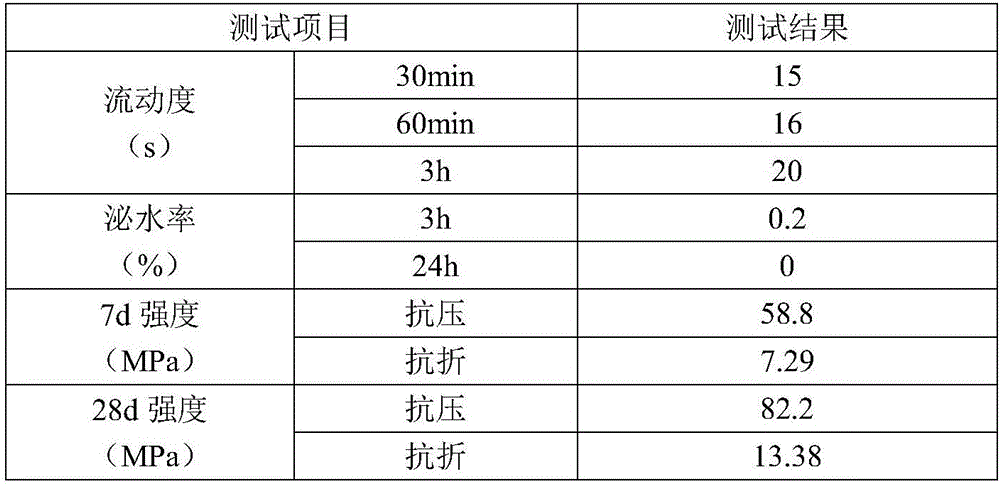

Embodiment 2

[0031] Calculated by weight components, the raw material components of the grouting material in this embodiment are as follows: including 1000 parts of cement, fly ash 80 share , 11 parts of graphene oxide, 90 parts of expansion agent, 15 parts of superplasticizer, 35 parts of rust inhibitor, and 330 parts of water.

[0032] The preparation method is the same as in Example 1. The technical indicators are shown in Table 2.

[0033] The technical indicator of table 2 embodiment 2

[0034]

[0035]

Embodiment 3

[0037] Calculated by weight components, the raw material components of the grouting material in this embodiment are as follows: 1050 parts of cement, 50 parts of fly ash, 6 parts of graphene oxide, 100 parts of expansion agent, 18 parts of high-efficiency water reducer, and 30 parts of rust inhibitor parts, 330 parts of water.

[0038] The preparation method is the same as in Example 1. The technical indicators are shown in Table 3.

[0039] The technical index of table 3 embodiment 3

[0040]

[0041] It can be seen from the foregoing examples that the grouting material obtained by the technical solution of the present invention has excellent workability, strength, volume stability and durability; Large and other problems, so as to meet the requirements of post-tensioned prestressed concrete structure construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com