Manufacturing method for ceramic powdery granule with coating and granule structure of ceramic powdery granule

A technology of ceramic powder and manufacturing method, applied in the field of building ceramics, can solve the problems of different quality of ceramic powder particles, unsatisfactory tile surface effect, uneven bonding medium, etc., achieve ideal surface effect, and avoid low manufacturing efficiency , Not easy to deform and crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

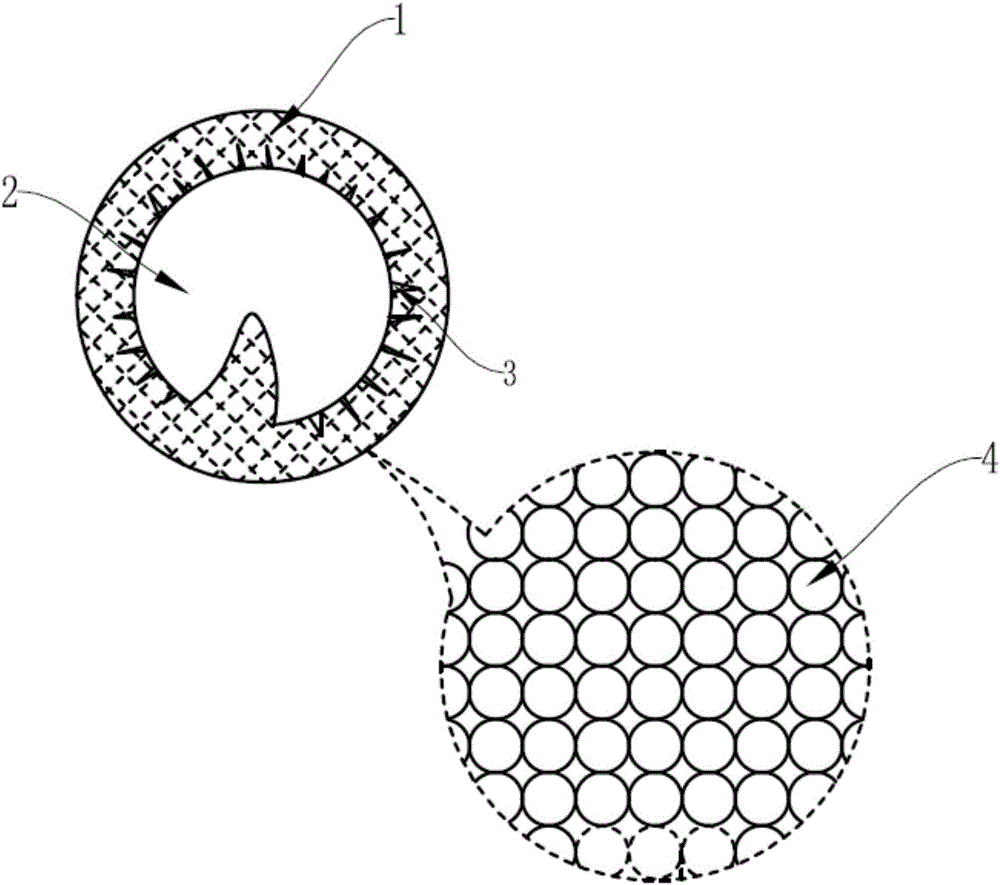

[0031] A method for manufacturing ceramic powder particles with a coating layer. In the known spray granulation process, the coating solution is sprayed into the slurry during the powder formation process, and the ceramic powder material with a coating layer is obtained after drying. particles.

[0032] To further illustrate, a method for manufacturing ceramic powder particles with a coating, comprising the steps of:

[0033] (1) Ceramic raw materials are made into slurry, and the slurry is dispersed and sprayed into the spray drying tower in the form of droplets, and the coating liquid is sprayed into the top of the atomized liquid droplets in the drying tower at the same time;

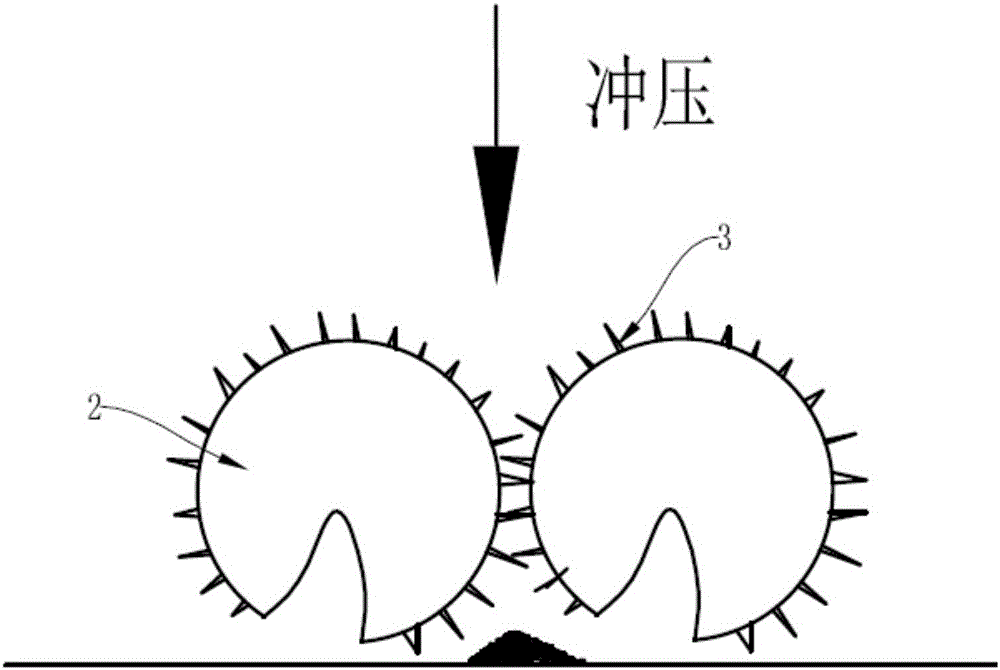

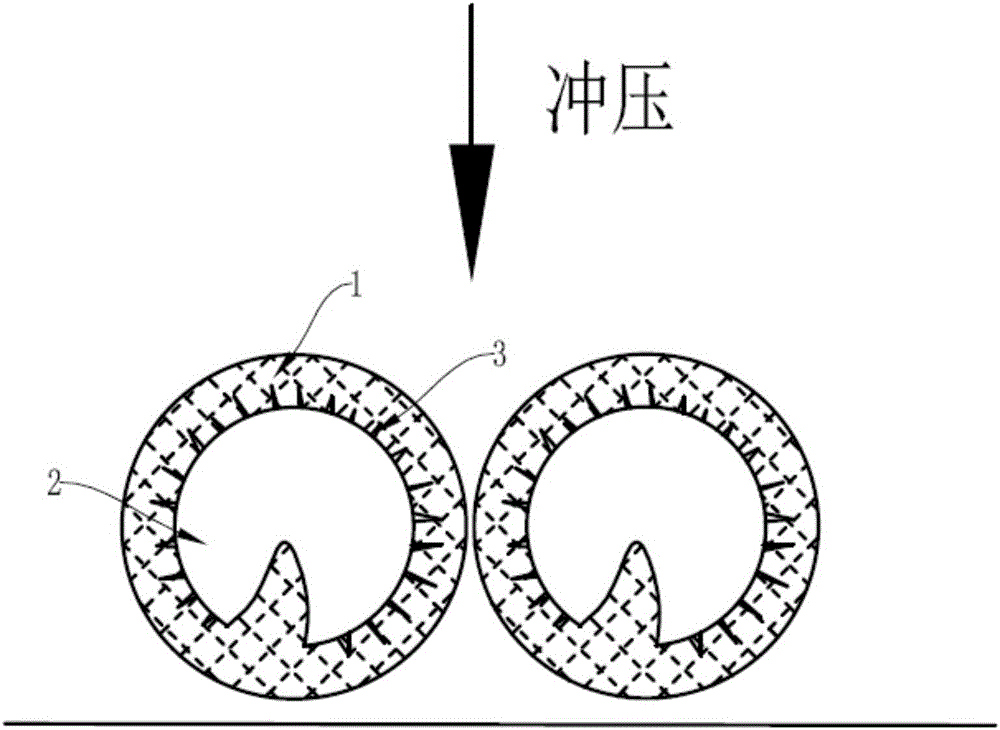

[0034] (2) During the drying process in the spray tower, the coating liquid coats the slurry particles formed by the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com