Preparation method of s-triazine ultraviolet absorbent UV-1577

A UV-1577, ultraviolet technology, applied in organic chemistry and other directions, can solve problems such as being unsuitable for industrial production, easy to cause fire, and many by-products, and achieve high product yield, environmental friendliness, and good reaction selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of s-triazine ultraviolet absorber UV-1577, the method consists of the following steps:

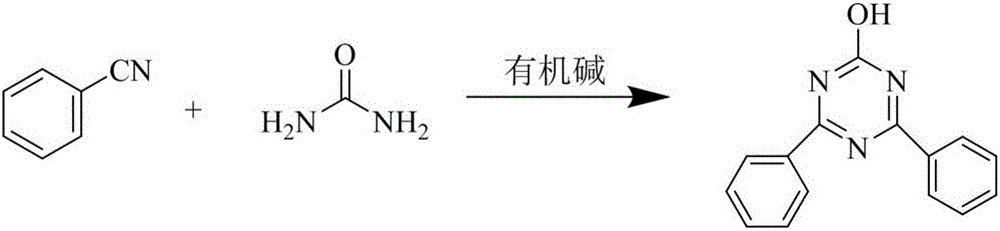

[0025] Preparation of Intermediate I

[0026] In 700mL of DMSO, add 60.1g (1.0mol) of urea and 78.02g (2.0mol) of sodium amide, stir to dissolve, add dropwise 412.2g (4.0mol) of benzonitrile, after the dropwise addition, continue at 30-50°C React 4-5h, pour into the aqueous solution (V 醋酸 :V 冰水 =1:1), filtered, dried, and recrystallized with DMF to obtain Intermediate I with a yield of 78.6%.

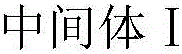

[0027] Preparation of Intermediate II

[0028] 249.1 g (1.0 mol) of intermediate I was dissolved in tetrahydrofuran, 475.9 g (4.0 mol) of thionyl chloride was added, refluxed for 3-4 hours, and excess thionyl chloride was evaporated under reduced pressure to obtain intermediate Ⅱ with a yield of 91.2% .

[0029] Preparation of Intermediate III

[0030] Dissolve 143.2g (1.3mol) of resorcinol and 267.1g (1.0mol) of intermediate II in 1000mL of chlorobenzene, add 160....

Embodiment 2

[0034] The ratio of the amount of urea, sodium amide, and benzonitrile is 1:2.5:4.5, and the others are the same as Example 1. The yield of intermediate I is 80.2%.

Embodiment 3

[0036] The ratio of the amount of urea, sodium amide, and benzonitrile is 1:3.0:5.0, and the others are the same as Example 1. The yield of intermediate I is 83.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com