Solid heat carrier heating device for biomass pyrolysis

A solid heat carrier and biomass pyrolysis technology, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil, etc. problems, to achieve the effect of solving high-speed and high-efficiency heating, accurate and stable feeding, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

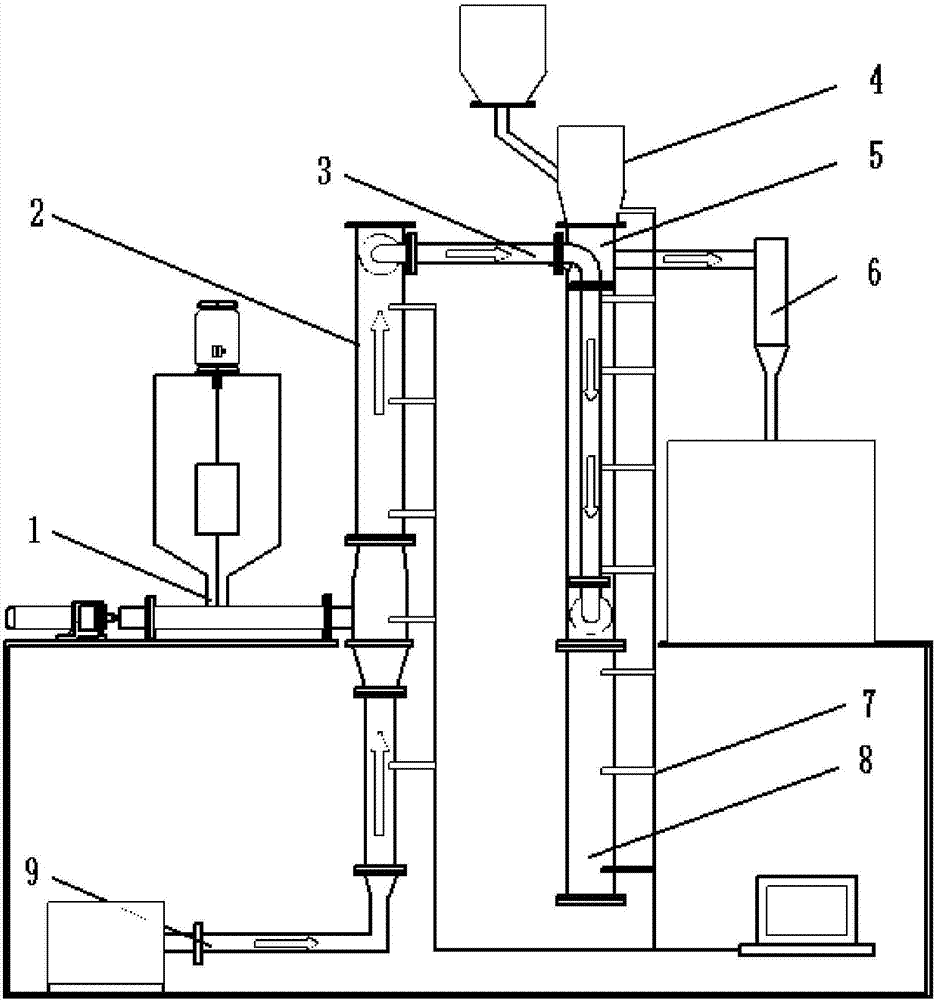

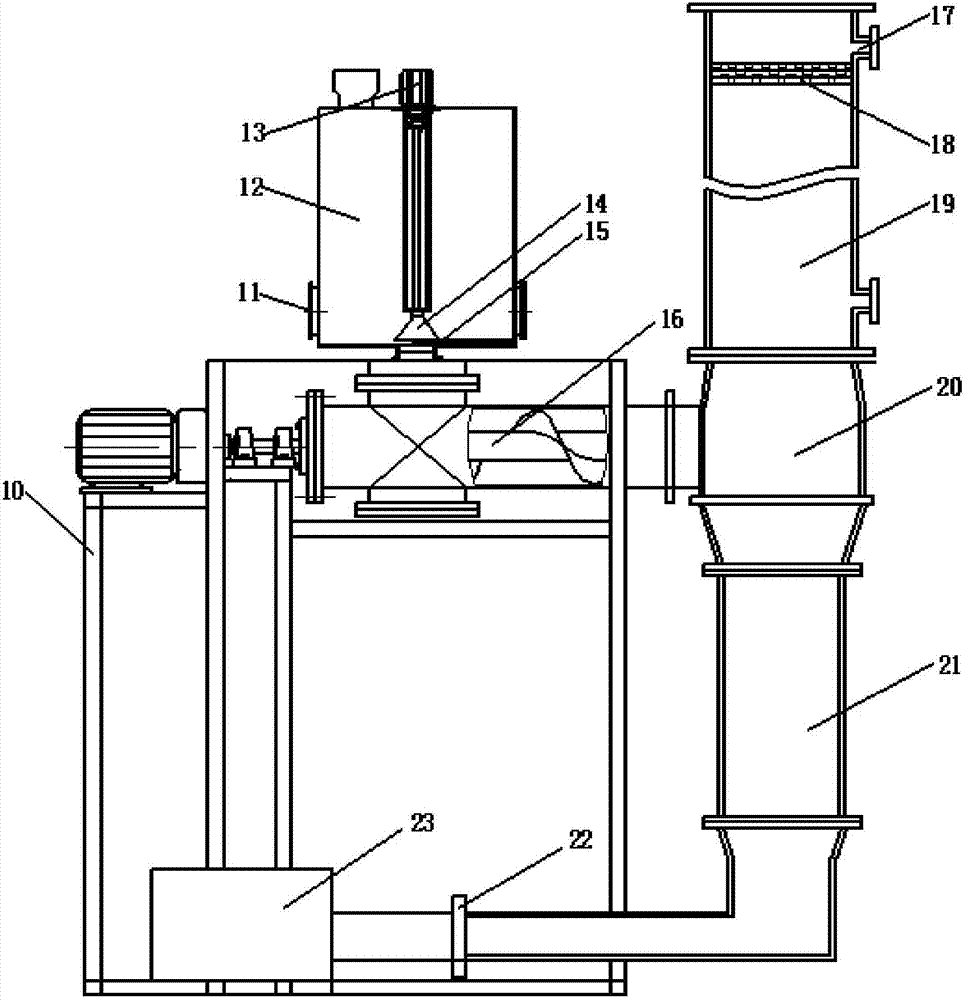

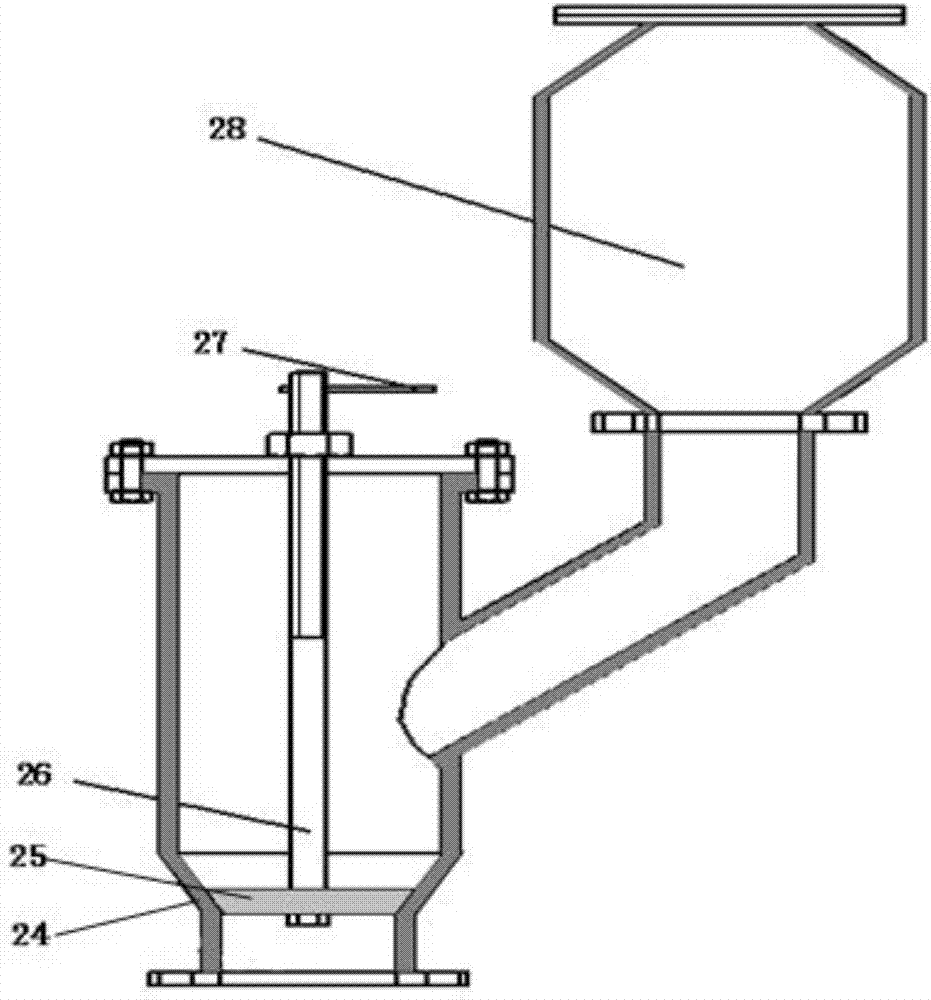

[0030] like figure 1 , figure 2 As shown, a solid heat carrier heating device for biomass pyrolysis includes a fluidized bed burner and a heat carrier heater, and the fluidized bed burner is connected to the heat carrier heater through a pipeline. The fluidized bed burner includes a burner body 2, the burner body 2 is connected to the biomass powder fuel feeder 1, and the burner body 2 is sequentially composed of a pre-distributor 21, an ignition chamber 20, and a combustion chamber 19 from bottom to top. , the flue gas purification chamber 18, wherein the predistributor 21 is connected with the air supply system 9, the high-temperature flue gas outlet 17 of the flue gas purification chamber 18 is connected with the heat carrier heating furnace 5 through the flue gas inlet pipe 3, and the biomass powder fuel feed Device 1 is connected to ignition chamber 20.

[0031] The fluidized bed burner is provided with a temperature sensor, and the air supply system 9 includes a Roots...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com