A method for preparing in-situ three-dimensional continuous reinforced al-based composites

A composite material and three-dimensional technology, which is applied in the field of preparing in-situ three-dimensional continuous reinforced Al-based composite materials, can solve the problems of low strength of prefabricated parts, complicated preparation process, easy defects (crack interface reaction, etc.), and achieve controllable design, combination high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Ti powder (purity greater than 99%, average particle size 20 μm), Al powder (purity greater than 99%, average particle size 40 μm) and graphite powder (purity greater than 99%, average particle size 40 μm) according to 2:1: 1 molar ratio mixed, and then fully ground in a glass mortar for 30min to obtain a mixed powder;

[0036] Step 2: Put the mixed powder into a cylindrical steel mold with an inner diameter of 10mm, and cold press it into a cylindrical green body with a thickness of 15mm under a radial pressure of 130MPa;

[0037] Step 3: Preheat the green body at 800°C for 2 minutes, then put it into an Al melt at 800°C, let it stand for 45s, take it out and cool it, so as to obtain an in-situ three-dimensional continuous reinforced Al-based composite material.

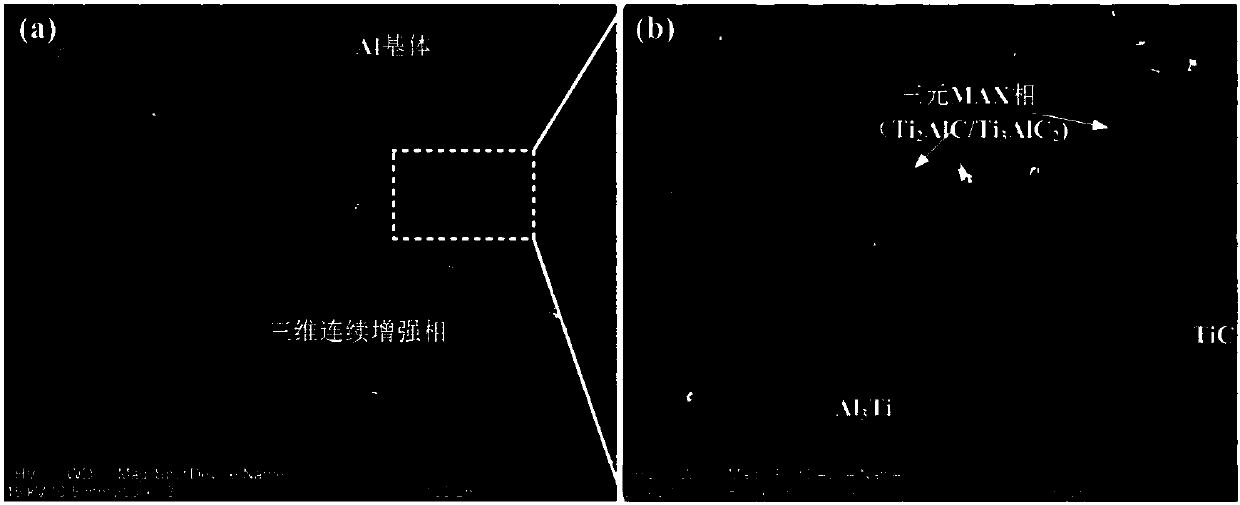

[0038] figure 1 It is a photo of the in-situ three-dimensional continuous reinforced Al-based composite obtained after the thermal explosion reaction of the Al-Ti-C body in the Al melt. It can be se...

Embodiment 2

[0040] Step 1: Ti powder (purity greater than 99%, average particle size 20 μm), Al powder (purity greater than 99%, average particle size 40 μm) and graphite powder (purity greater than 99%, average particle size 40 μm) according to 2:1.1: The molar ratio of 1 was mixed, and then fully ground in a glass mortar for 50min to obtain a mixed powder;

[0041] Step 2: Put the mixed powder into a cylindrical steel mold with an inner diameter of 10mm, and cold press it under a radial pressure of 50MPa into a cylindrical green body with a thickness of 20mm;

[0042] Step 3: Preheat the green body at a temperature of 850°C for 1.5min, then put it into an Al melt at 850°C, let it stand for 45s, take it out and cool it, so as to obtain an in-situ three-dimensional continuous reinforced Al-based composite material.

Embodiment 3

[0044] Step 1: Ti powder (purity greater than 99%, average particle size 20 μm), Al powder (purity greater than 99%, average particle size 40 μm) and graphite powder (purity greater than 99%, average particle size 40 μm) according to 2:1: 1 molar ratio mixed, and then fully ground in a glass mortar for 60min to obtain a mixed powder;

[0045] Step 2: Put the mixed powder into a cylindrical steel mold with an inner diameter of 10mm, and cold press it into a cylindrical green body with a thickness of 10mm under a radial pressure of 100MPa;

[0046] Step 3: Preheat the green body at a temperature of 700°C for 3 minutes, then put it into an Al melt at 700°C, let it stand for 60 seconds, take it out and cool it, so as to obtain an in-situ three-dimensional continuous reinforced Al-based composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com