Axial and radial combined deep groove ball thrust ball bearing

A thrust ball bearing and radial bearing technology, applied in the fields of bearing structures, machine tool spindles, and gearboxes, can solve the problems of high requirements on shaft machining accuracy, difficult to meet the requirements of axial load, and large installation space requirements for casings, etc. To achieve the effect of compact structure, increased life, and increased axial bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A detailed description will be given below of specific embodiments of the present invention according to the accompanying drawings.

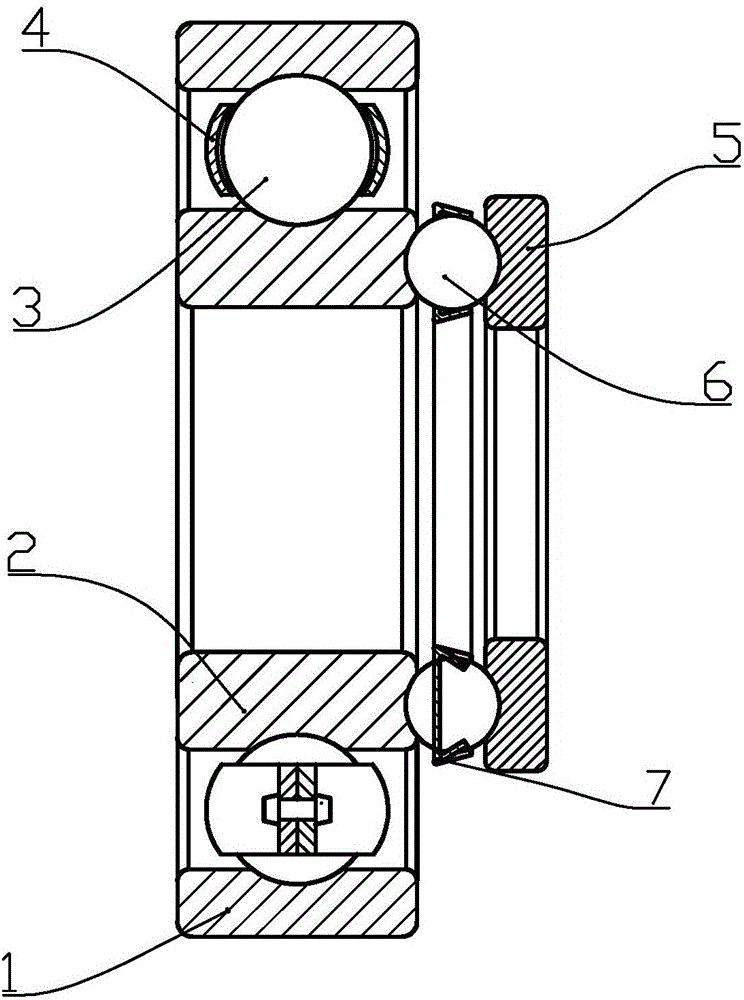

[0019] according to Figure 1 to Figure 5 As shown, a radial and axial composite deep groove ball thrust ball bearing described in this embodiment includes a radial bearing assembly and an axial bearing assembly; the radial bearing assembly includes an outer ring 1, an inner ring 2 and Radial bearing steel balls 3 rolled between the outer ring and the inner ring, the radial bearing steel balls are installed on a radial cage 4;

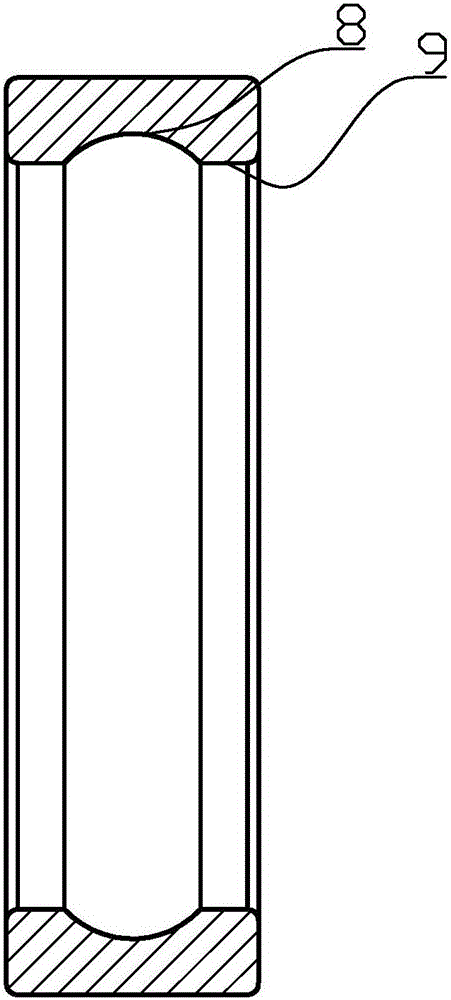

[0020] The inner wall of the outer ring is formed with an outer channel surface 8, and the two ends of the outer ring are formed with outer and inner diameters 9 of the outer ring;

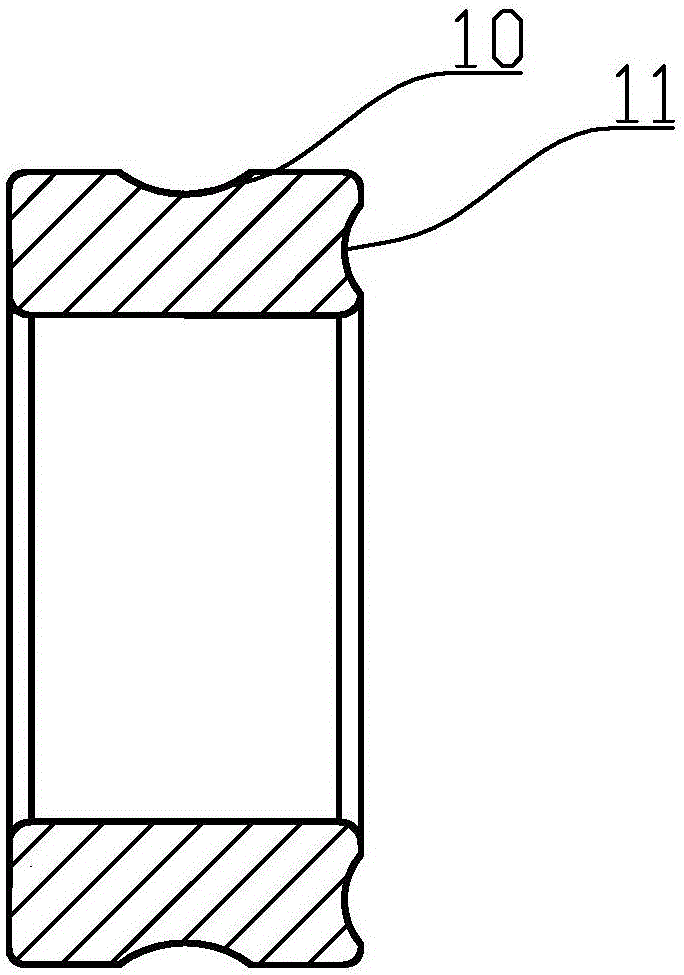

[0021] The outer wall of the inner ring is formed with an inner channel surface 10, one end surface of the inner ring is flat, and a shaft ring channel 11 is formed on the other end surface;

[0022] Both ends of the inner ring are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com