Clamp for high-temperature high-cycle fatigue test of metal plate-shaped sample

A technology of high-cycle fatigue and test fixtures, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems that the plate-shaped sample is in a blank state, cannot simulate special structural parts, and cannot meet the test requirements, etc., and achieve good cooling effect , Avoid deviation, good clamping ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This embodiment is a fixture for high temperature and high cycle fatigue testing of metal plate samples.

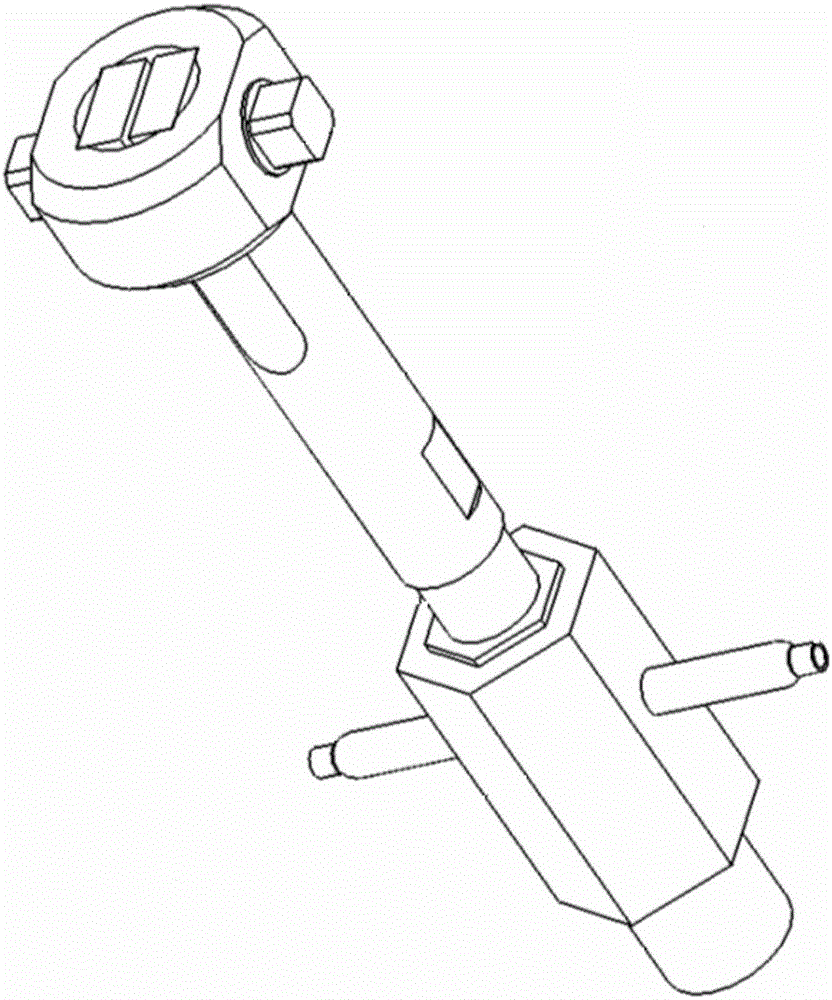

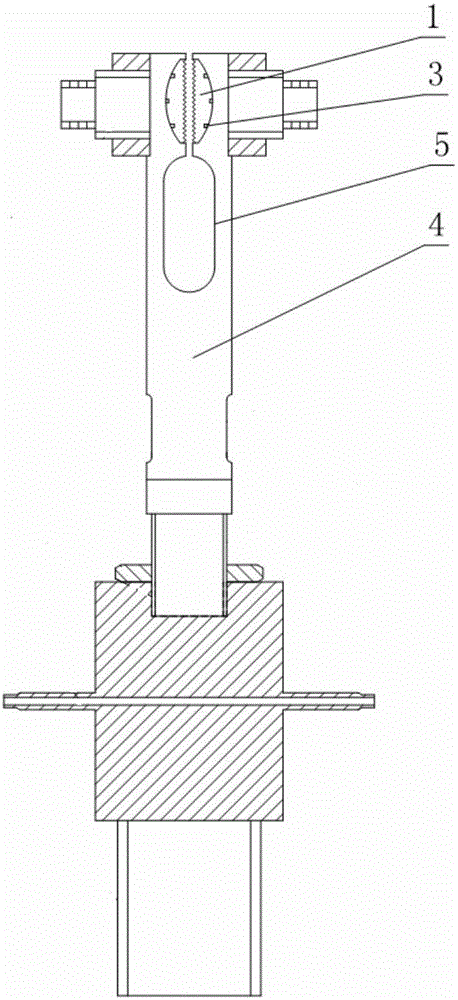

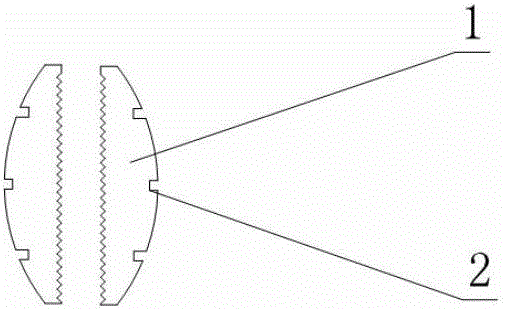

[0029] refer to Figure 1 to Figure 9 , The high-temperature high-cycle fatigue test fixture for metal plate samples in this embodiment consists of a clamp body and a water-cooled base. The clamp body is installed on the water-cooled base, and the water-cooled base is fixedly installed on the testing machine. Among them, the clamp body includes chuck 1, chuck slot 2, tenon 3, chuck strut 4, expansion wrench 5, chuck strut external thread 6, fastening ring 7, screw hole 8, fastening bolt 9. Multiple chuck slots 2 are processed on the arc surface of one side of the chuck 1, and the other side of the chuck 1 is serrated. The chuck 1 is divided into several pairs according to different thicknesses, which are used for test pieces of different thicknesses. The upper end of the chuck strut 4 is processed with an inner concave arc surface, and two opposite inner concave a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com