Wind speed tester based on graphene material and manufacture method thereof

A graphene and tester technology, applied in the field of sensors, can solve problems such as complex hardware circuit structure, immature application, general dynamic performance, etc., and achieve the effects of good biocompatibility, convenient processing, high sensitivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

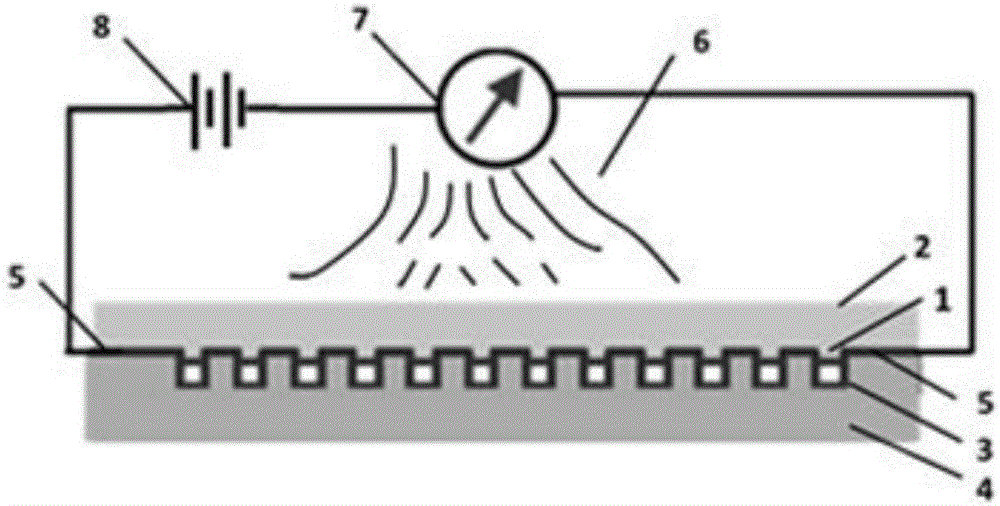

[0026] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. The experimental methods for which specific conditions are not indicated in the examples are usually in accordance with conventional conditions or in accordance with the conditions suggested by the manufacturer.

[0027] The preparation steps of the wind speed tester based on graphene materials are as follows:

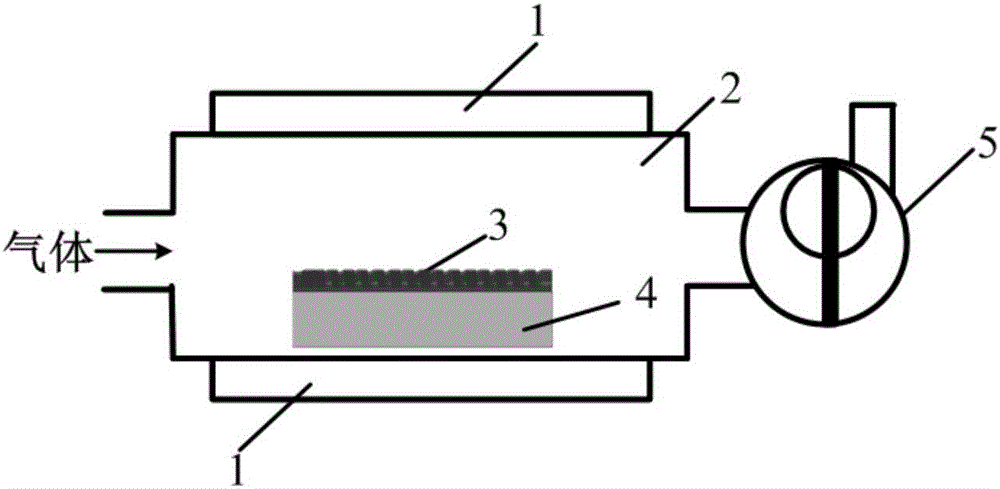

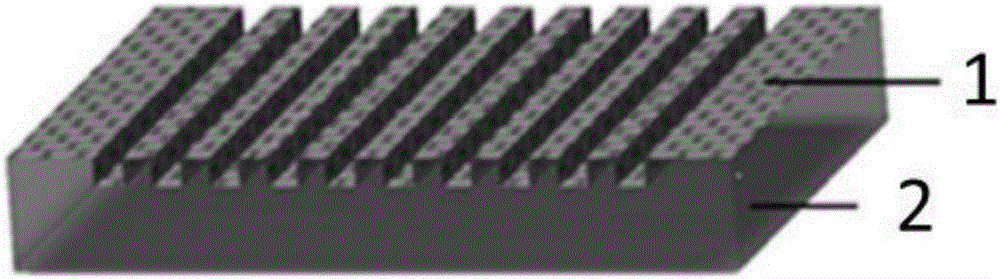

[0028] Step 1: Preparation of graphene film and PDMS bilayer structure

[0029] First, the substrate copper foil was placed in acetone, 95 vol% ethanol, and pure water for ultrasonic cleaning for 2 min each, dried with nitrogen, and then placed in the vacuum chamber of a tubular CVD system to prepare graphene to obtain a graphene film. like figure 1 As shown, 1 is a CVD tube furnace, 2 is a gas reaction chamber, 3 is a graphene material, 4 is a growth substrate, and 5 is a mechanical pump. A layer of PDMS with a thickness of 50um w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com