Control circuit provided with positive and negative wave independent dead zone control elements

A dead zone control and control circuit technology, applied in the direction of electrical components, plasma, etc., can solve the problems of signal tailing, inconsistent pulse width, large switching loss, etc., to achieve reduced switching loss, good switching signal characteristics, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

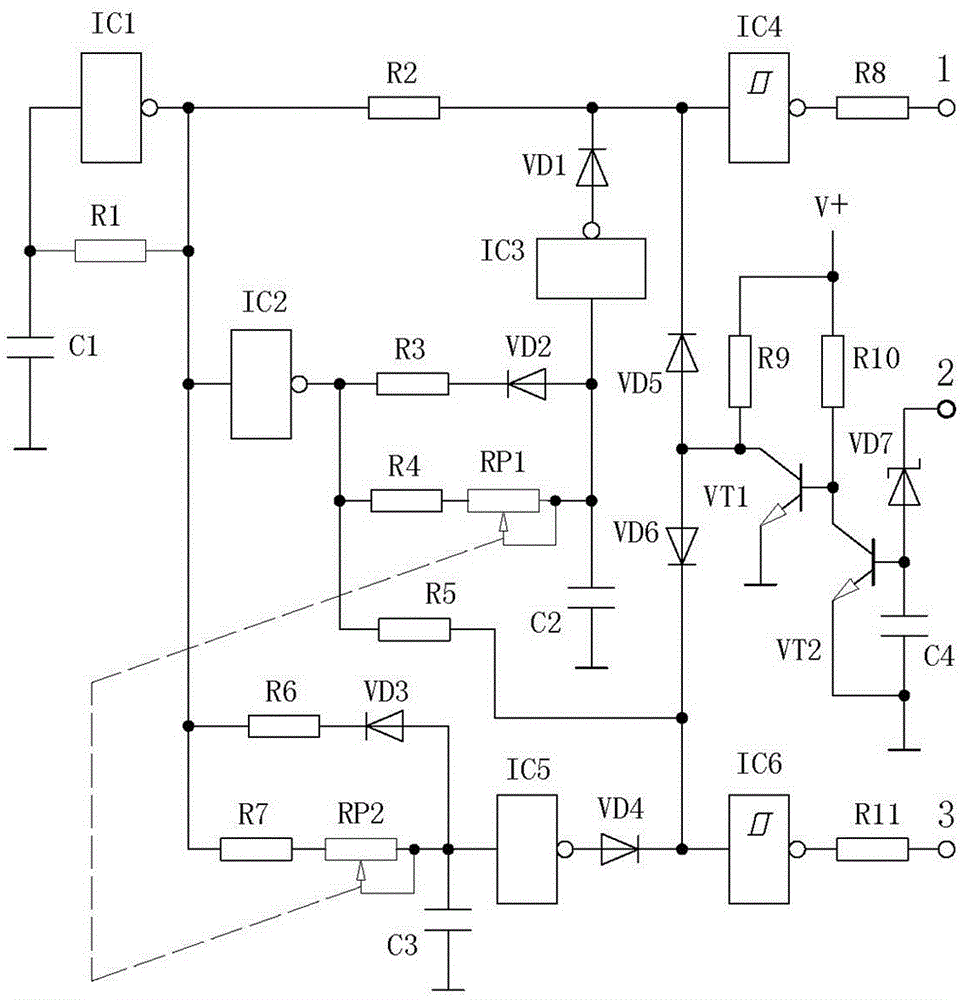

[0017] Embodiment 1 Attached figure 1 In the embodiment shown, the control circuit with positive and negative wave independent dead zone control elements is mainly composed of a NOT gate circuit, resistors, capacitors and diodes. The NOT gate circuit includes an oscillation gate (IC1), an inverting gate (IC2), a second A delay gate (IC3), a first output gate (IC4), a second delay gate (IC5) and a second output gate (IC6), the oscillation resistor (R1) is connected between the input and output of the oscillation gate (IC1) Between, there is an oscillation capacitor (C1) between the input end of the oscillation gate (IC1) and the ground wire, the output end of the oscillation gate (IC1) is connected to the first end of the first isolation resistor (R2), the inverting gate (IC2 ), the first end of the second discharge resistor (R6) and the first end of the second dead zone control resistor (R7), the second end of the first isolation resistor (R2) is connected to the first output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com