Functional beverage capable of reducing blood fat and preparation method thereof

A functional, blood-lipid-lowering technology, applied in the functions of food ingredients, sugar-containing food ingredients, food science, etc., can solve the problems of non-sterilized treatment and achieve the effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

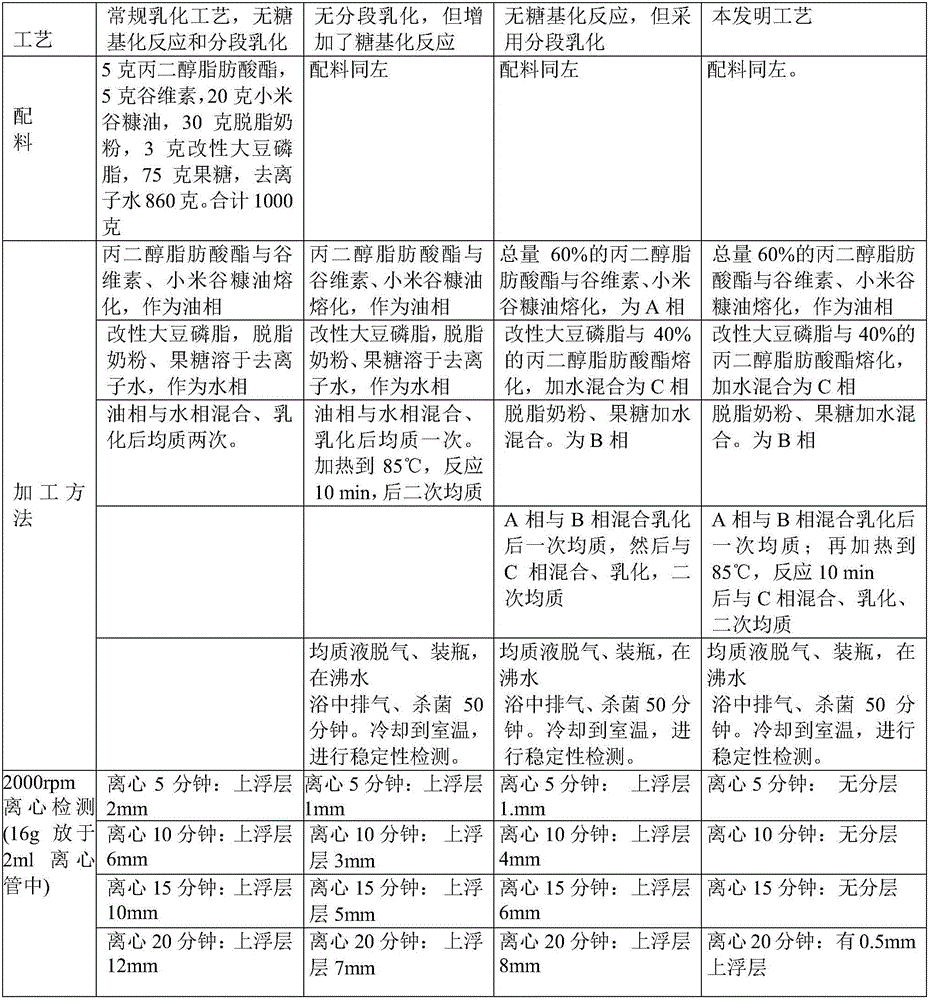

Method used

Image

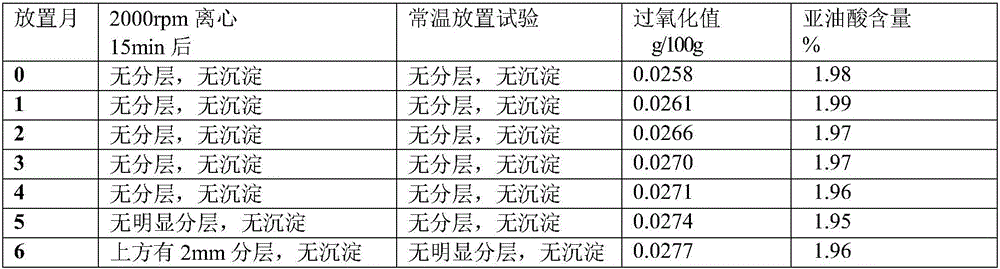

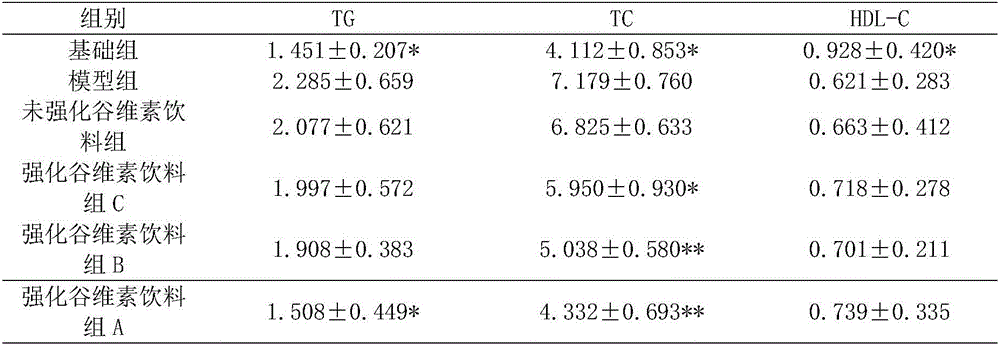

Examples

Embodiment 1

[0021] Put 3 grams of propylene glycol fatty acid ester and 5 grams of oryzanol into 20 grams of millet bran oil, heat and melt, as phase A; dissolve 30 grams of skimmed milk powder and 75 grams of fructose in 200 grams of deionized water as phase B solution; After heating and melting the modified soybean lecithin and 2 g of propylene glycol fatty acid ester, add 400 g of deionized water at 80° C. and mix evenly at 2000 rpm to form phase C. Pour phase B heated to 85°C into phase A at the same temperature and mix, stir and emulsify at 5000rpm for 6 minutes to form an emulsion with high oil content; then use a high-pressure homogenizer to homogenize once at 30MPa, and then heat to 85°C, After 10 minutes of reaction, phase D was obtained. Add 263 grams of deionized water after mixing phase D and phase C, so that the total mass of all ingredients is 1000 grams. After the mixture was heated to 75°C, it was sheared and emulsified at 3000rpm for 4 minutes to form an oil-in-water emu...

Embodiment 2

[0026]Put 4 grams of monoglycerides of fatty acids and 7 grams of oryzanol into 30 grams of millet bran oil, heat and melt, as phase A; dissolve 30 grams of skim milk powder and 90 grams of maltose in 240 grams of deionized water as phase B solution; After heating and melting the hydrophilic monoglyceride and 3 g of monoglyceride, add 400 g of deionized water at 70-85° C. and mix evenly at 2000 rpm to form phase C. Pour phase B heated to 75°C into phase A at the same temperature and mix, stir and emulsify at 6000rpm for 5 minutes to form an emulsion with high oil content; then use a high-pressure homogenizer to homogenize once at 35MPa, and then heat to 86°C, After 10 minutes of reaction, phase D was obtained. After mixing phase D and phase C, add 191.5 grams of deionized ingredients to make the total mass of all ingredients 1000 grams. After the mixture was heated to 80°C, it was sheared and emulsified at 4000rpm for 2 minutes to form an oil-in-water emulsion with low oil co...

Embodiment 3

[0030] 2.5 grams of ethylene glycol fatty acid ester and 6 grams Put oryzanol into 25 grams of millet bran oil, heat and melt it as phase A; dissolve 15 grams of skim milk protein powder and 60 grams of glucose in 180 grams of deionized water as the solution of phase B; dissolve 1.3 grams of polyglycerol ester, 1.2 hydrophilic After heating and melting monoglyceride and 1.5 g of ethylene glycol fatty acid ester, add 400 g of deionized water at 85° C. and mix evenly at 3000 rpm to form phase C. Pour phase B heated to 85°C into phase A at the same temperature and mix, stir and emulsify at 4000rpm for 8 minutes to form an emulsion with high oil content; then use a high-pressure homogenizer to homogenize once at 25MPa, and then heat to 82°C, After 10 minutes of reaction, phase D was obtained. After mixing phase D and phase C, add 315.5 grams of deionized water, so that the total mass of all ingredients is 1000. After the mixture was heated to 80°C, it was sheared and emulsified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com