Garlic skin dietary fiber and double-screw extrusion and enzymolysis modification preparation technology and application thereof

A technology of twin-screw extrusion and dietary fiber, which is applied in food extrusion, application, food drying, etc., can solve the problems of insufficient physiological functions, etc., and achieve easy industrial production, good water absorption, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

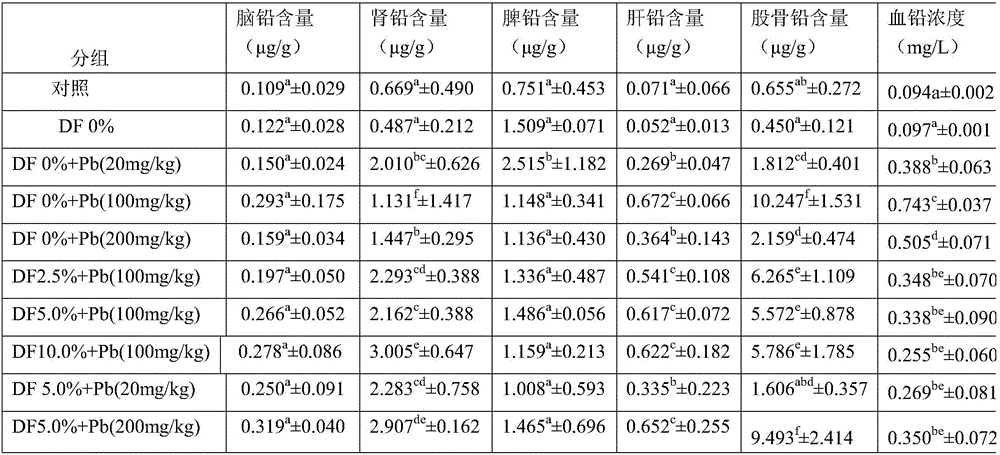

Image

Examples

Embodiment 1

[0027] Example 1: Garlic skin soluble dietary fiber was prepared by combining enzymatic hydrolysis with twin-screw extrusion. Adjust the moisture content of the garlic skin to 40%, the feed rate is 25rpm, the screw speed is 150rpm, the screw distribution temperature is 190-170-150-90-60°C, extrusion treatment under these conditions, freeze-dry for 36 hours after treatment, crush the freeze-dried sample , pass through a 60-mesh sieve to obtain the modified garlic skin dietary fiber finished product 1, further carry out enzymolysis, the enzymolysis process and subsequent steps are the same as the control example, obtain the modified garlic skin dietary fiber finished product 2, after determination, the garlic skin dietary fiber The content of soluble dietary fiber in skin is 11.37%.

Embodiment 2

[0028] Embodiment 2: test process is the same as embodiment 1, and its difference is that the screw distribution temperature is 170-150-130-90-60 ℃, obtains the modified garlic skin dietary fiber finished product 2, and the content of garlic skin soluble dietary fiber is 13.56 %.

Embodiment 3

[0029] Embodiment 3: test process is the same as embodiment 1, and its difference is that screw rod distribution temperature is 150-130-110-90-60 ℃, obtains modified garlic skin dietary fiber finished product 2, and the content of garlic skin soluble dietary fiber is 12.34 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com