Filter pond blow-down pipe quick sand discharge device

An emptying tube and fast technology, applied in the direction of filtration separation, fixed filter element filter, pipe/pipe joint/pipe fitting, etc. Empty pipe loss and other problems, to achieve the effect of convenient treatment of debris blockage, convenient maintenance and maintenance, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

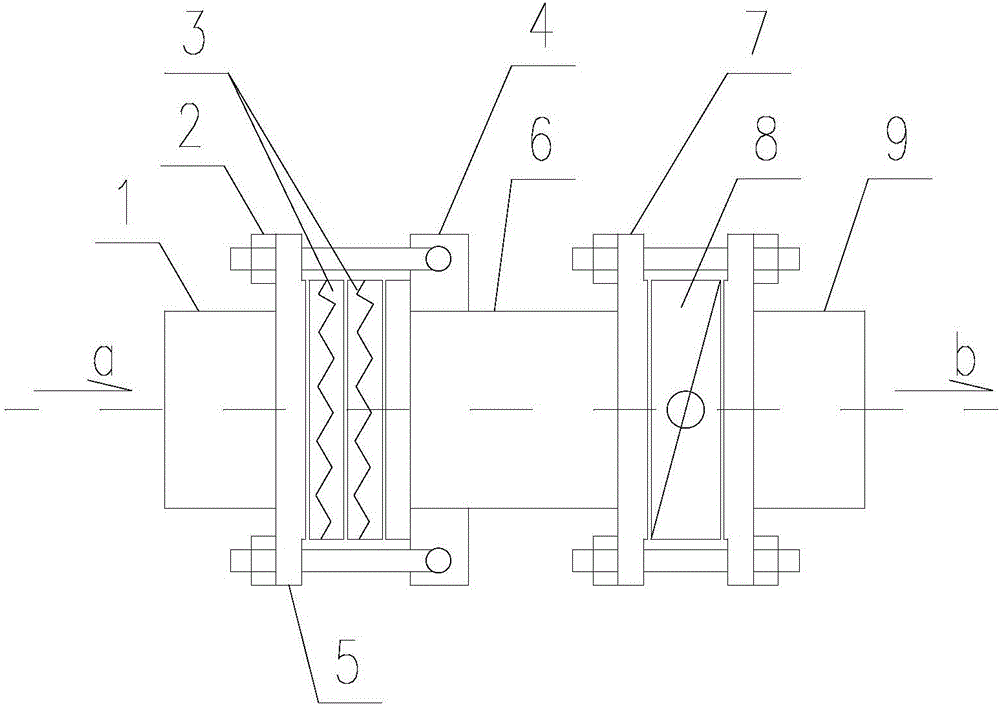

[0018] The device of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] figure 1 Middle: 1. Water inlet pipe 2. Swivel bolts and nuts 3. Stainless steel filter screen 4. Swivel lugs 5. Quick opening flanges and gaskets 6. Drain tube 7. Butterfly valve flanges and fasteners 8. Manual butterfly valve 9. Water outlet connection. a. Water inlet b. Water outlet. The device of the present invention includes water inlet and outlet pipes, diversion pipes, joint bolt quick-opening flanges, filter screen modules or components, manual butterfly valves and supporting fasteners. The filter screen module is composed of clamping steel rings, stainless steel filter screen , gaskets, the above parts are assembled to form a container. Adopting the flange plus welding structure, a cylinder with flanges at both ends and two straight pipes with flanges at one end are connected by fasteners as the shell, and the filter screen and manual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com