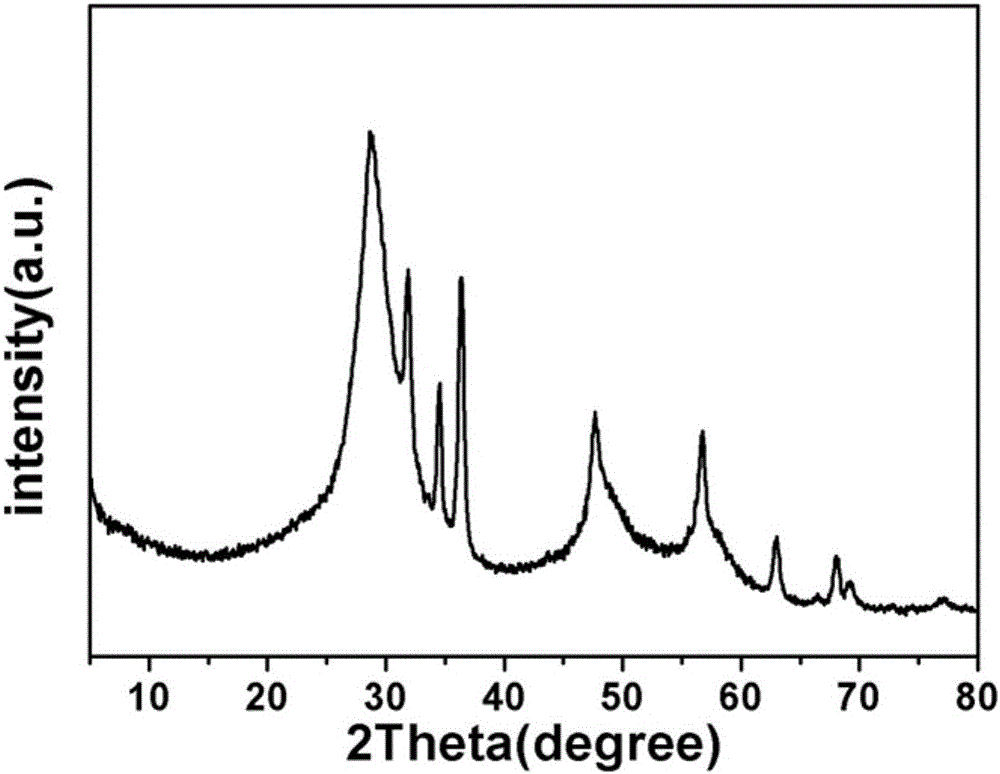

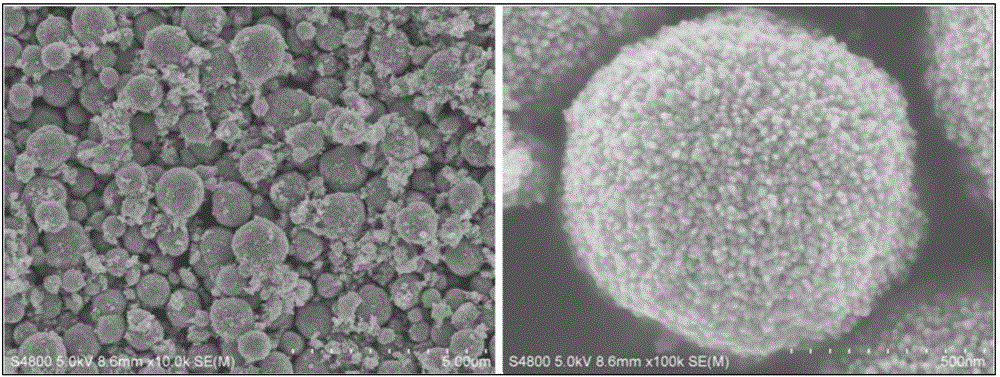

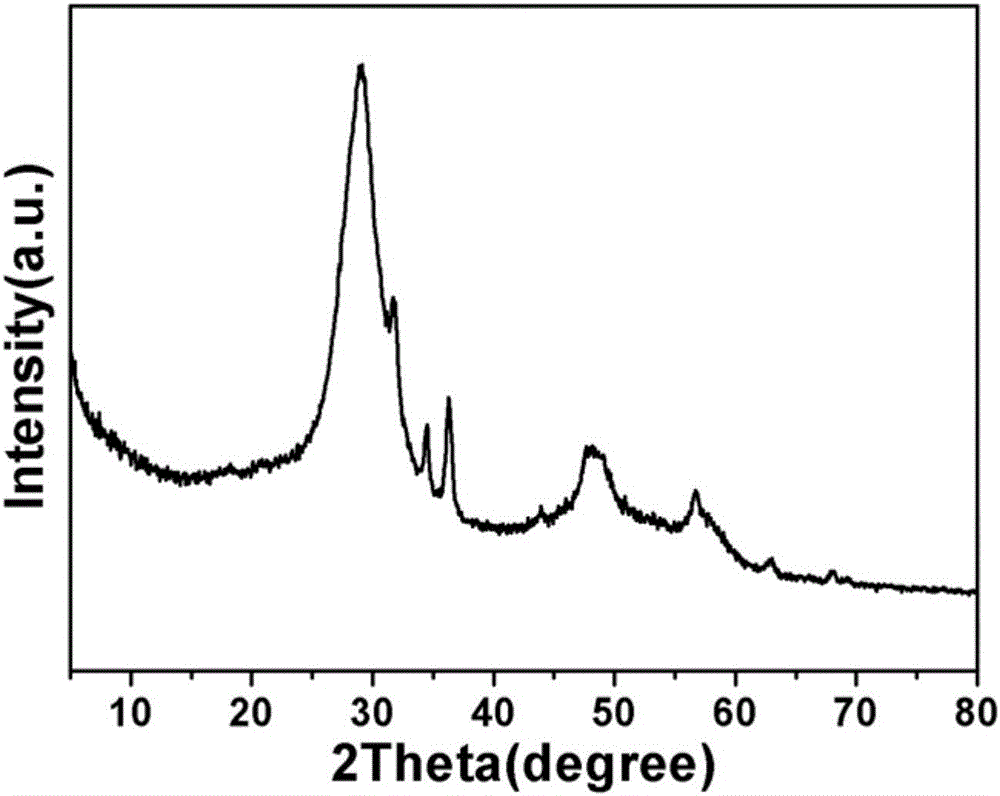

ZnO/ZnS/CdS composite of porous core-shell structure and preparation method thereof

A composite material and shell structure technology, which is applied in catalyst activation/preparation, hydrogen/synthesis gas production, chemical instruments and methods, etc., can solve the problems of narrow light absorption range, low quantum efficiency, and low hydrogen production performance, and achieve the goal of preparing The method is simple, the quantum efficiency is improved, and the effect of infiltration is beneficial

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Prepare the ZnO / ZnS / CdS composite material of porous core-shell structure, the steps are as follows:

[0030] 1) Preparation of porous ZnO microspheres: Add 1g of zinc acetate into 50mL of diethylene glycol, mix and stir evenly to obtain solution I, then put the obtained solution I into a reaction kettle, seal it and heat it to 160°C for constant temperature crystallization Reaction, after 24 hours of reaction, perform suction filtration, washing, and drying to obtain porous ZnO microspheres;

[0031] 2) Preparation of ZnO / ZnS porous microspheres: add 0.2 g of ZnO porous microspheres obtained in step 1) and 0.4 g of thioacetamide into 50 mL of water, stir and mix well to obtain suspension II, and then Liquid II was put into the reaction kettle, sealed and heated to 90°C for ion exchange reaction. After 7 hours, suction filtration, washing and drying were performed to obtain ZnO / ZnS porous microspheres;

[0032] 3) Preparation of ZnO / ZnS / CdS composite material with poro...

Embodiment 2

[0036] Prepare the ZnO / ZnS / CdS composite material of porous core-shell structure, the steps are as follows:

[0037] 1) Preparation of porous ZnO microspheres: Add 1.2g of zinc acetate into 50mL of diethylene glycol, mix and stir evenly (stirring temperature is 25°C, stirring speed is 700r / min), to obtain solution I, and then put the obtained solution I into Put it into a reaction kettle, seal it and heat it to 180°C for a constant temperature crystallization reaction. After reacting for 24 hours, perform suction filtration, washing, and drying to obtain porous ZnO microspheres;

[0038]2) Preparation of ZnO / ZnS porous microspheres: Add 0.2 g of ZnO porous microspheres obtained in step 1) and 0.4 g of thioacetamide into 50 mL of water, stir well and mix evenly (stirring temperature is 25 ° C, stirring rate is 700 r / min) to obtain the suspension II, then put the suspension II into the reaction kettle, seal it and heat it to 100°C for ion exchange reaction, after 6h, carry out ...

Embodiment 3

[0042] Prepare the ZnO / ZnS / CdS composite material of porous core-shell structure, the steps are as follows:

[0043] 1) Preparation of porous ZnO microspheres: Add 1.5g of zinc acetate into 50mL of diethylene glycol, mix and stir evenly (stirring temperature is 25°C, stirring rate is 700r / min) to obtain solution I, and then put the obtained solution I into Put it into a reaction kettle, seal it and heat it to 150°C for a constant temperature crystallization reaction. After reacting for 7 hours, perform suction filtration, washing, and drying to obtain porous ZnO microspheres;

[0044] 2) Preparation of ZnO / ZnS porous microspheres: add 0.2 g of the ZnO porous microspheres obtained in step 1) and 0.2 g of thioacetamide into 50 mL of water, stir well and mix evenly (stirring temperature is 25 ° C, stirring rate is 700 r / min) to obtain the suspension II, then put the suspension II into the reaction kettle, seal it and heat it to 90°C for ion exchange reaction, after 7h, carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com