Preparation method and detachment method of detachable magnetic-microsphere-supported noble metal catalyst

A technology of noble metal catalysts and magnetic microspheres, applied in chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the difficulty, lack, and lack of separation of carriers and particles Connecting precious metal catalysts and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

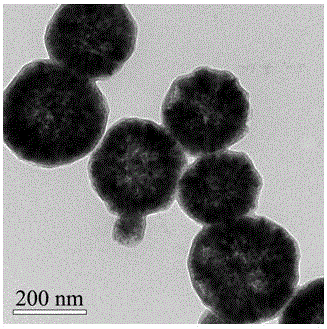

[0049] 1. Preparation of carbon-coated ferroferromagnetic microspheres (MFC):

[0050] Weigh 3.6 g of FeCl 3 ·6H 2 O, 0.72 g of trisodium citrate and 4.8 g of anhydrous sodium acetate in a 250 ml three-necked flask, then add 90 ml of ethylene glycol and 10 ml of absolute ethanol and stir evenly, then transfer to the reaction kettle at 200 °C React for 10 h. Then washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C for later use.

[0051] Weigh the above-prepared Fe 3 o 4 0.1 g, add 30 ml of deionized water to ultrasonically disperse evenly, then add 2 g of glucose to dissolve, transfer to the reaction kettle at 200°C for 12 h. After the reaction, wash with deionized water and absolute ethanol three times respectively, and dry in a vacuum oven at 60°C for later use.

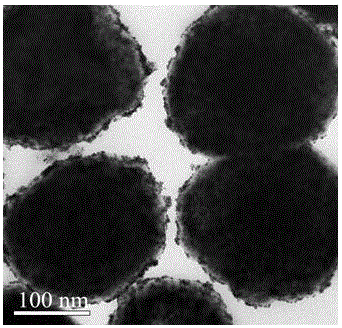

[0052] 2. Preparation of cyclodextrin-modified carbon-coated ferric oxide magnetic microspheres (MFC / β-CD):

[0053] Weigh 1 g of MFC in a three-neck flask, add 2...

Embodiment 2

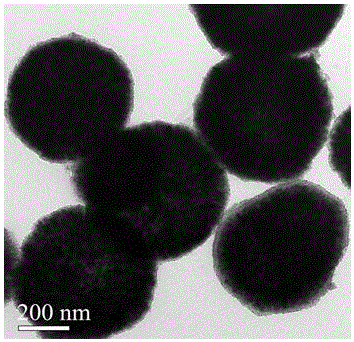

[0059] 1. Preparation of carbon-coated ferroferromagnetic microspheres (MFC):

[0060] Weigh 3.6 g of FeCl 3 ·6H 2 O, 0.72 g of trisodium citrate and 4.8 g of anhydrous sodium acetate in a 250 ml three-necked flask, then add 90 ml of ethylene glycol and 10 ml of absolute ethanol and stir evenly, then transfer to the reaction kettle at 200 °C React for 10 h. Then washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C for later use.

[0061] Weigh the above-prepared Fe 3 o 4 0.1 g, add 30 ml of deionized water to ultrasonically disperse evenly, then add 2 g of glucose to dissolve, transfer to the reaction kettle at 200°C for 12 h. After the reaction, wash with deionized water and absolute ethanol three times respectively, and dry in a vacuum oven at 60°C for later use.

[0062] 2. Preparation of cyclodextrin-modified carbon-coated ferric oxide magnetic microspheres (MFC / β-CD):

[0063] Weigh 0.5 g of MFC in a three-necked flask, a...

Embodiment 3

[0069] 1. Preparation of carbon-coated ferroferromagnetic microspheres (MFC):

[0070] Weigh 3.6 g of FeCl 3 ·6H 2 O, 0.72 g of trisodium citrate and 4.8 g of anhydrous sodium acetate in a 250 ml three-necked flask, then add 90 ml of ethylene glycol and 10 ml of absolute ethanol and stir evenly, then transfer to the reaction kettle at 200 °C React for 10 h. Then washed three times with deionized water and absolute ethanol, and dried in a vacuum oven at 60°C for later use.

[0071] Weigh the above-prepared Fe 3 o 4 0.1 g, add 30 ml of deionized water to ultrasonically disperse evenly, then add 2 g of glucose to dissolve, transfer to the reaction kettle at 200°C for 12 h. After the reaction, wash with deionized water and absolute ethanol three times respectively, and dry in a vacuum oven at 60°C for later use.

[0072] 2. Preparation of cyclodextrin-modified carbon-coated ferric oxide magnetic microspheres (MFC / β-CD):

[0073] Weigh 0.5 g of MFC in a three-necked flask, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com