a mno 2 /Graphene nanocomposite material and its prepared electrode

A nanocomposite material and graphene composite technology, which is applied in the fields of material preparation and electrochemical analysis, can solve the problem of high detection limit of caffeic acid detection electrode, and achieve the effects of good storage stability, low detection limit and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

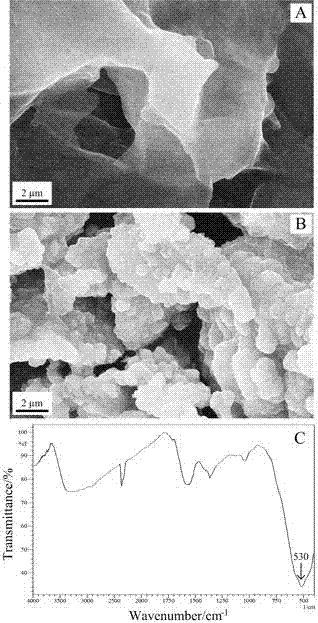

[0055] Example 1 MnO 2 / Preparation of graphene nanocomposites

[0056] A kind of MnO 2 / The preparation method of graphene nanocomposite material, comprises the steps:

[0057] S11. Combining mesoporous carbon with KMnO 4 Mix, add deionized water and stir for 12 hours to obtain a suspension;

[0058] S12. Add concentrated sulfuric acid to the suspension, and continue to stir for 1.2h to obtain a mixture;

[0059] S13. Heating the mixture to 85°C and maintaining a constant temperature for 1.5h to obtain a reaction solution;

[0060] S14. Dilute the reaction solution 5 times with deionized water, cool to room temperature, and precipitate;

[0061] S15. Collect the resulting precipitate with a filter membrane with a pore size of 0.25 mm, wash and dry to obtain the MnO 2 / graphene nanocomposites;

[0062] Mesoporous carbon, KMnO described in step S11 4 The dosage ratio of mixing and deionized water is 1g: 12g: 450mL;

[0063] The concentrated sulfuric acid described in...

Embodiment 2

[0066] Example 2 MnO 2 / Preparation of graphene nanocomposites

[0067] A kind of MnO 2 / The preparation method of graphene nanocomposite material, comprises the steps:

[0068] S11. Combining mesoporous carbon with KMnO 4 Mix, add deionized water and stir for 8 hours to obtain a suspension;

[0069] S12. Add concentrated sulfuric acid to the suspension, and continue to stir for 2h to obtain a mixture;

[0070] S13. Heating the mixture to 90° C. and maintaining the constant temperature for 2 hours to obtain a reaction solution;

[0071] S14. Dilute the reaction solution 6 times with deionized water, cool to room temperature, and precipitate;

[0072] S15. Collect the resulting precipitate with a filter membrane with a pore size of 0.20 mm, wash and dry to obtain the MnO 2 / graphene nanocomposites;

[0073] Mesoporous carbon, KMnO described in step S11 4 The dosage ratio of deionized water is 1g: 10g: 600mL;

[0074] The concentrated sulfuric acid described in step S...

Embodiment 3

[0076] Example 3 MnO 2 / Preparation of graphene nanocomposites

[0077] A kind of MnO 2 / The preparation method of graphene nanocomposite material, comprises the steps:

[0078] S11. Combining mesoporous carbon with KMnO 4 Mix, add deionized water and stir for 24 hours to obtain a suspension;

[0079] S12. Add concentrated sulfuric acid to the suspension, and continue to stir for 0.5h to obtain a mixture;

[0080] S13. Heating the mixture to 75°C and maintaining a constant temperature for 0.5h to obtain a reaction solution;

[0081] S14. Dilute the reaction solution 3 times with deionized water, cool to room temperature, and precipitate;

[0082] S15. Collect the resulting precipitate with a filter membrane with a pore size of 0.30 mm, wash and dry to obtain the MnO 2 / graphene nanocomposites;

[0083] Mesoporous carbon, KMnO described in step S11 4 The dosage ratio of mixing and deionized water is 1g: 8g: 400mL;

[0084] The concentrated sulfuric acid described in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com