A method of doping graphene in a substrate

A graphene and base material technology, which is applied in the field of graphene composite material preparation, can solve problems such as uneven mixing, easy oxidation of polyester slices, and poor spinning effect, so as to improve dispersion effect, avoid sticking phenomenon, overcome The effect of the sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

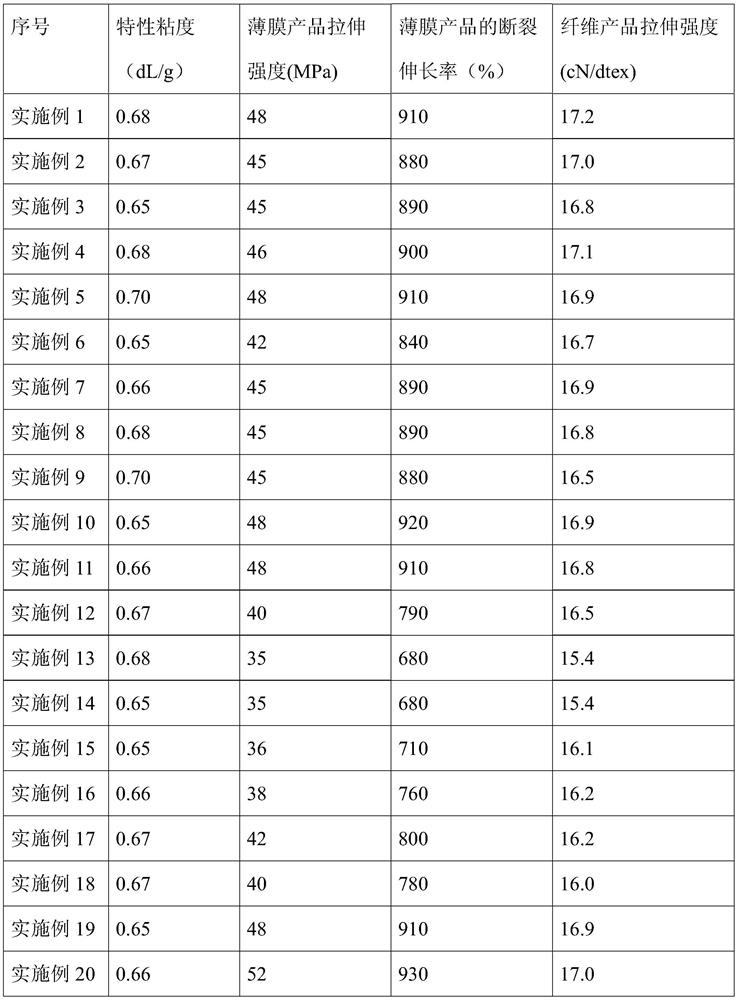

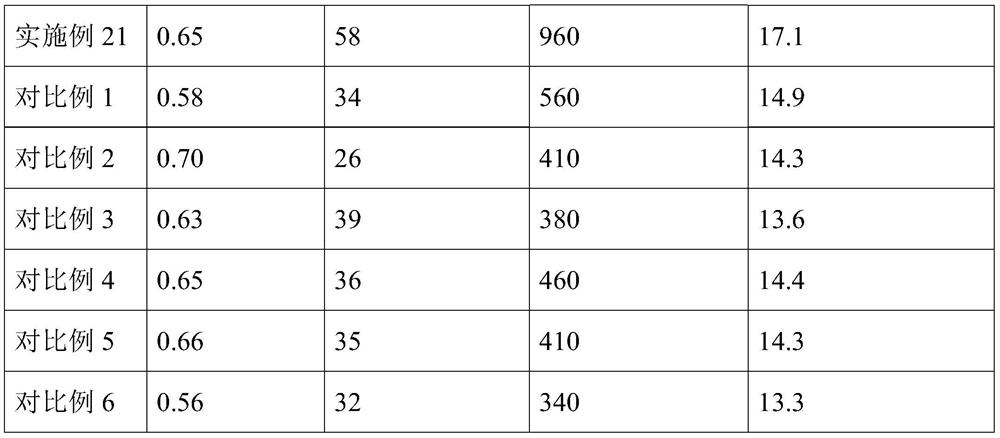

Examples

Embodiment 1

[0067] A method for doping graphene in a PE substrate, comprising the steps of:

[0068] (1) Get 1kg PE base material, pulverize, obtain the particle that average particle diameter is 100 μ m, add the graphene powder of 1000g wherein, mix uniformly, obtain mixed pulverized material;

[0069] (2) In addition, 10kg of PE substrates were taken and pulverized to obtain particles with an average particle diameter of 2mm;

[0070] (3) Mix the mixed pulverized material in step (1) with the pulverized material in step (2).

[0071] Subsequently, the material obtained in step (3) can be melted, extruded and granulated to obtain a functional masterbatch.

[0072] Or, the material obtained in the step (3) is melted, and then made into a desired shape product.

Embodiment 2

[0074] The difference from Example 1 is that the average particle diameter in step (1) is replaced by 50 μm.

Embodiment 3

[0076] The difference from Example 1 is that the average particle diameter in step (1) is replaced by 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com