Expanding flame-retardant silicone rubber and preparation method thereof

A technology of intumescent flame retardant and intumescent flame retardant, which is applied in the field of polymers, can solve the problems that the reinforcement effect of flame retardants cannot be explained, and the mechanical properties of silicone rubber have not been clarified, so as to reduce adverse effects, reduce combustion performance, and improve The effect of flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

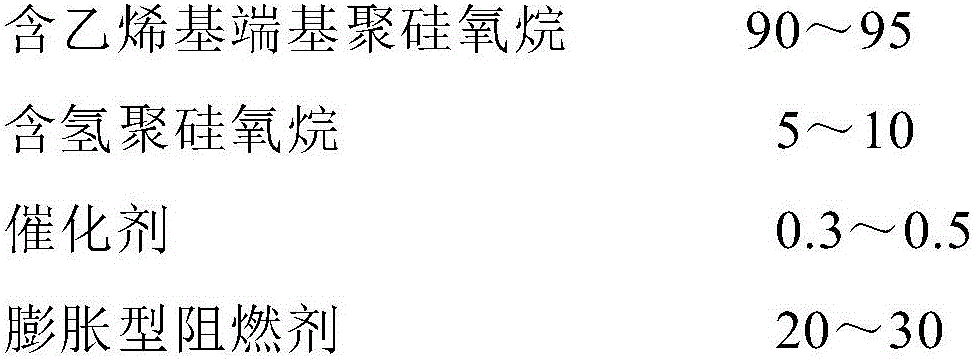

Method used

Image

Examples

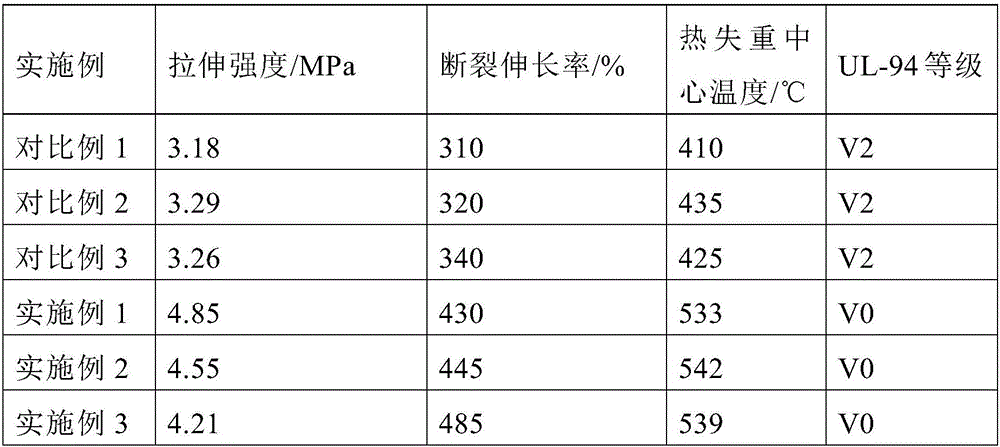

Embodiment 1

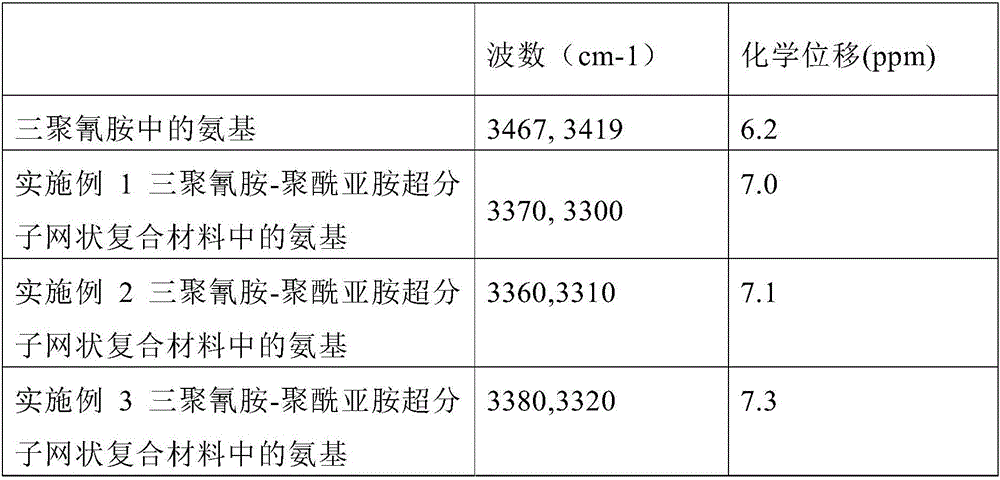

[0036] Add 10g of melamine into the four-necked bottle, add 70mL of toluene solution, at room temperature and pass N 2 Stir for 30min under normal conditions, then add 40g of polyimide, raise the temperature to 100°C, stir for 1h, keep for 2h, and then vacuumize to remove toluene. The precipitate was washed with a solvent and centrifuged again, and the above steps were repeated until no unreacted substance was detected in the washing solution. The precipitate was vacuum-dried at 80° C. for 10 hours to obtain a melamine-polyimide supramolecular network composite material.

[0037] Add 14.3g of ammonium polyphosphate and 4.2g of antioxidant 1010 into 90 grams of vinyl-terminated polysiloxane, and add 5 grams of hydrogen-containing polysiloxane and 0.3 gram of chloroplatinic acid, at room temperature at 3000 rpm Stirring / minute to mix for 50 minutes. Add 1.4 g of melamine-polyimide supramolecular network composite material to the above mixture, and stir for 20 minutes at a cert...

Embodiment 2

[0040] Add 15g of melamine into the four-necked bottle, add 80mL of toluene solution, at room temperature and pass N 2 Stir for 40min under normal conditions, then add 60g of polyimide, raise the temperature to 110°C, stir for 1.5h, keep for 3h, and then vacuumize to remove toluene. The precipitate was washed with a solvent and centrifuged again, and the above steps were repeated until no unreacted substance was detected in the washing liquid. The precipitate was vacuum-dried at 90° C. for 9 hours to obtain a melamine-polyimide supramolecular network composite material.

[0041]Add 17.8g of ammonium polyphosphate and 5.4gg of antioxidant 1010 into 90 grams of vinyl-terminated polysiloxane, add 5 grams of hydrogen-containing polysiloxane and 0.3 gram of chloroplatinic acid, and turn at room temperature at 3500 / min stirring to mix for 40 minutes. Add 1.8 g of melamine-polyimide supramolecular network composite material to the above mixture, and stir for 25 minutes at a certa...

Embodiment 3

[0044] Add 20g of melamine into the four-necked bottle, add 90mL of toluene solution, at room temperature and pass N 2 Stir for 50min under normal conditions, then add 80g of polyimide, raise the temperature to 100°C, stir for 2h, keep for 4h, and then vacuumize to remove toluene. The precipitate was washed with a solvent and centrifuged again, and the above steps were repeated until no unreacted substance was detected in the washing liquid. The precipitate was vacuum-dried at 100° C. for 8 hours to obtain a melamine-polyimide supramolecular network composite material.

[0045] Add 21.4g of ammonium polyphosphate and 6.4g of antioxidant 1010 into 90 grams of vinyl-terminated polysiloxane, and add 5 grams of hydrogen-containing polysiloxane and 0.3 gram of chloroplatinic acid, at room temperature at 4000 rpm / min stirring to mix for 30 minutes. Add 2.1 g of melamine-polyimide supramolecular network composite material to the above mixture, and stir for 30 minutes at a certain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com