Method and device for controlling laser peening parameters to monitor surface roughness of blade

A surface roughness and laser peening technology, which is applied in the field of controlling laser peening parameters to monitor the surface roughness of blades, can solve problems such as performance loss, aero-engine safety, reliability and fatigue strength reduction, and weaken the mechanical properties of blades. Achieve the effects of improving fatigue life, ensuring consistency, accurate prediction and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

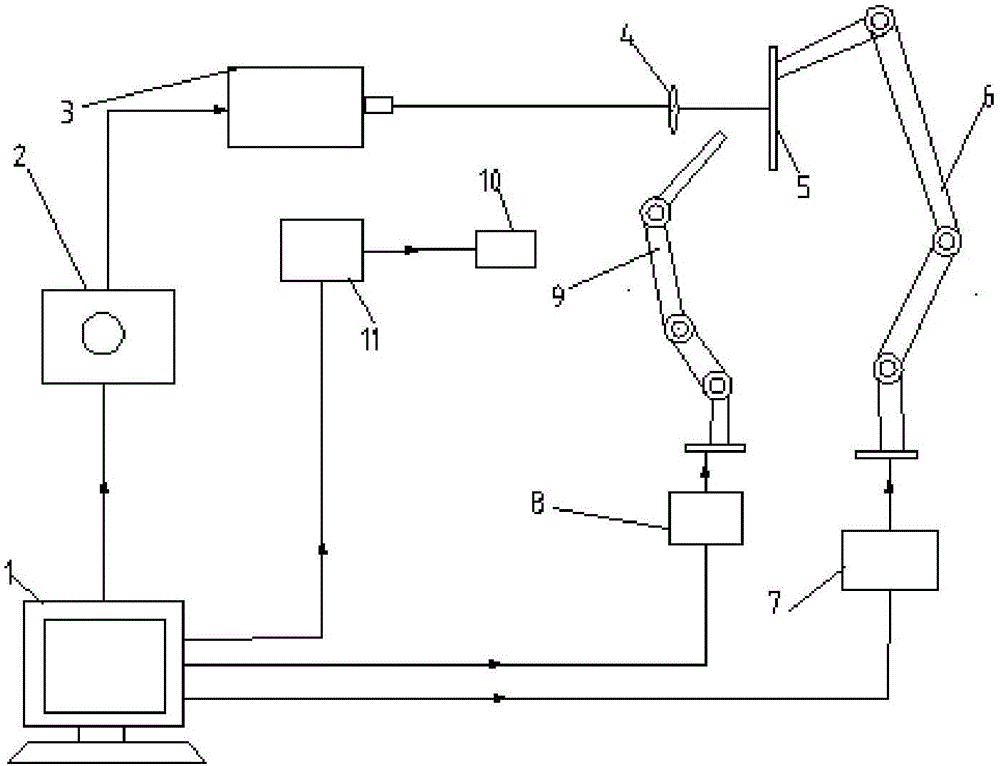

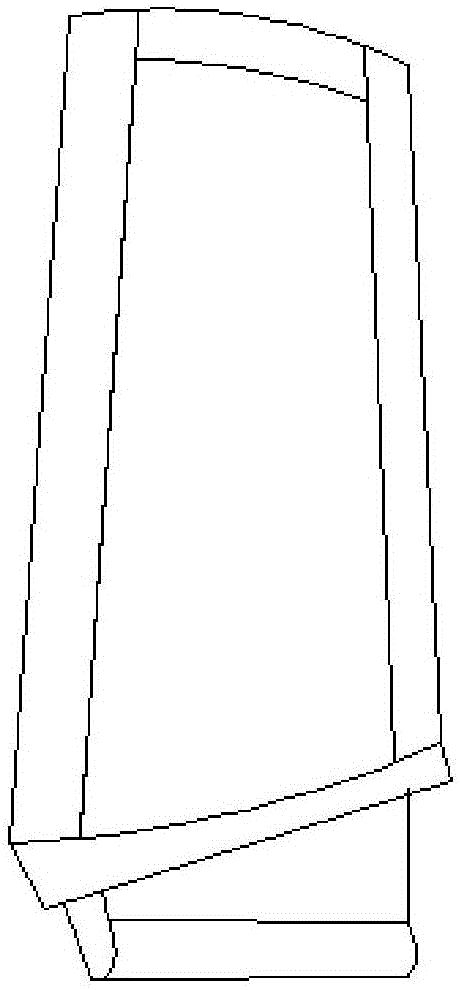

[0024] Such as Figure 1-5 As shown, a method for controlling the laser peening parameters to monitor the surface roughness of the blade comprises the following steps:

[0025] Step 1: Measure the surface roughness of the variable cross-section thin-walled complex blade (5) before laser shot peening through a transmission mirror (4) with the help of a surface roughness measuring instrument (10) to obtain the measured value before processing, and put the The measured value before processing is transmitted to the computer control system (1) through the information collection system (11);

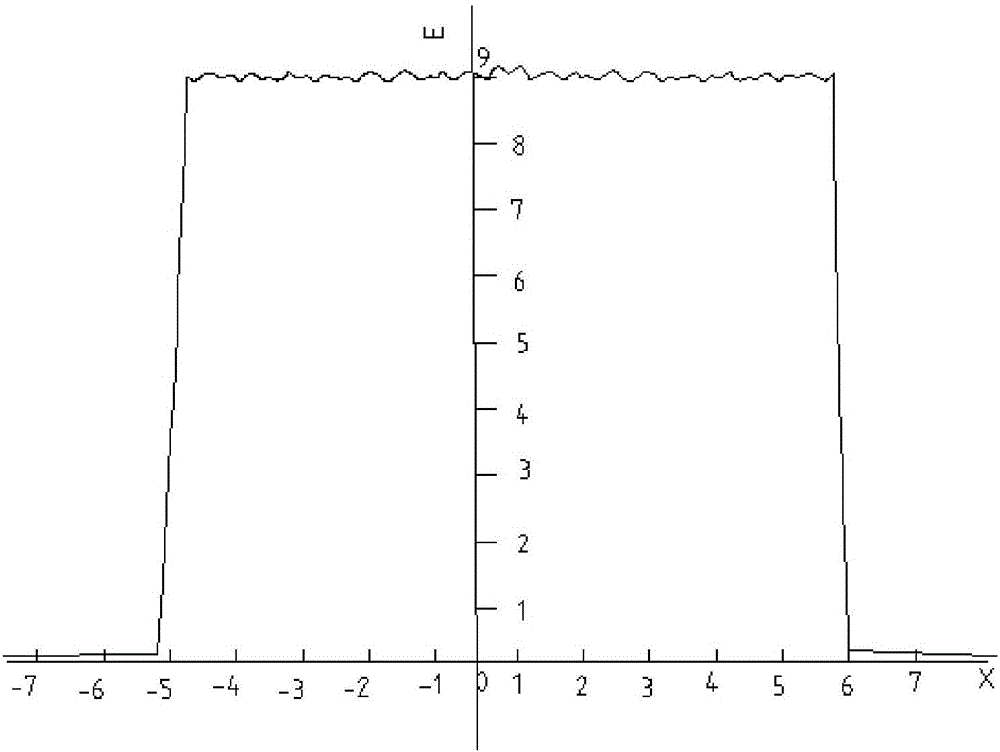

[0026] Step 2: The computer control system (1) according to the surface roughness accuracy requirements required by the variable cross-section thin-walled complex blade (5), the flat top variation and roughness of the laser peening beam built in the computer control system (1) In the database of the corresponding relationship between them, the laser peening parameters to be surface treated ar...

Embodiment 2

[0036] Such as Figure 1-5 As shown, a method for controlling the laser peening parameters to monitor the surface roughness of the blade comprises the following steps:

[0037] Step 1: Measure the surface roughness of the variable cross-section thin-walled complex blade (5) before laser shot peening through a transmission mirror (4) with the help of a surface roughness measuring instrument (10) to obtain the measured value before processing, and put the The measured value before processing is transmitted to the computer control system (1) through the information collection system (11);

[0038] Step 2: The computer control system (1) according to the surface roughness accuracy requirements required by the variable cross-section thin-walled complex blade (5), the flat top variation and roughness of the laser peening beam built in the computer control system (1) In the database of the corresponding relationship between them, the laser peening parameters to be surface treated ar...

Embodiment 3

[0048] Such as Figure 1-5 As shown, a method for controlling the laser peening parameters to monitor the surface roughness of the blade comprises the following steps:

[0049] Step 1: Measure the surface roughness of the variable cross-section thin-walled complex blade (5) before laser shot peening through a transmission mirror (4) with the help of a surface roughness measuring instrument (10) to obtain the measured value before processing, and put the The measured value before processing is transmitted to the computer control system (1) through the information collection system (11);

[0050] Step 2: The computer control system (1) according to the surface roughness accuracy requirements required by the variable cross-section thin-walled complex blade (5), the flat top variation and roughness of the laser peening beam built in the computer control system (1) In the database of the corresponding relationship between them, the laser peening parameters to be surface treated ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com