Hot-dip galvanized strip steel production system

A production system and hot-dip galvanizing technology, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve the problems affecting the efficiency of galvanizing production line, time-consuming and laborious, and difficulty in connecting strips, and reduce manpower. The effect of maintenance cost, avoiding production loss, saving wiring space and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structural features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings.

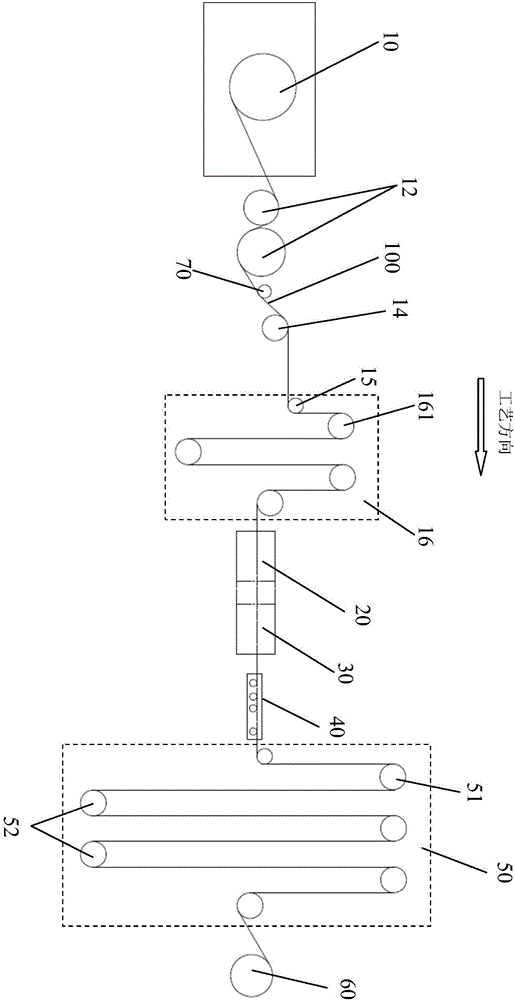

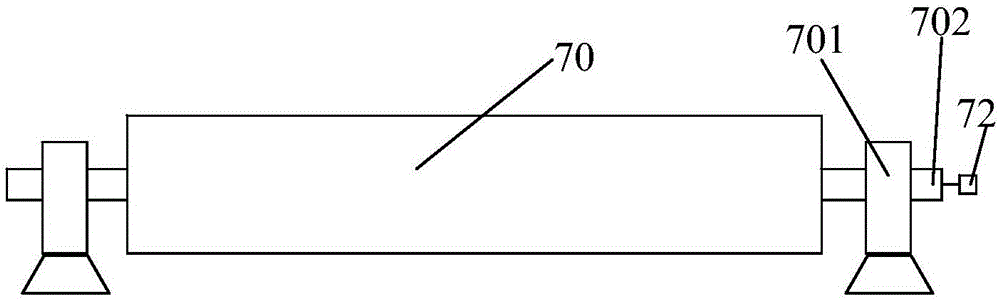

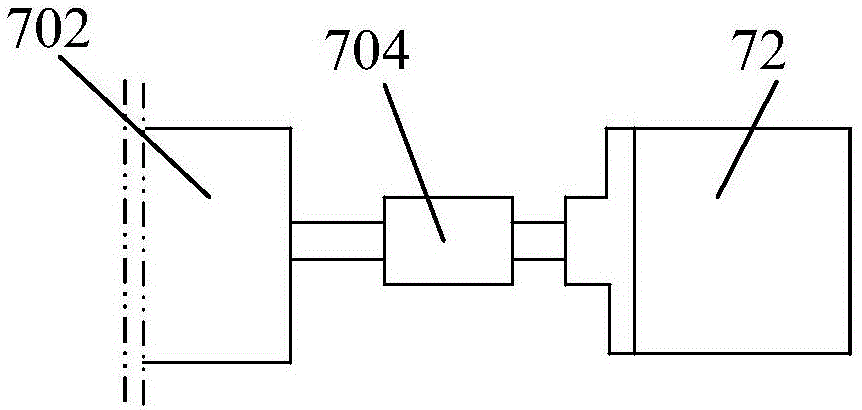

[0014] refer to figure 1 Shown is a schematic structural diagram of a hot-dip galvanized steel strip production system according to an embodiment of the present invention, and the direction of the arrow in the figure is the direction of the strip steel processing process, that is, the direction of the strip steel conveyance. The production system includes a steel strip storage warehouse 10, an S roller group 12, conveying rollers 14, 15, a tension stretching roller group 16, an annealing furnace 20, a galvanizing tank 30, a heat preservation system 40, a cooling system 50 and a traction take-up roller 60, the monitoring roller 70 arranged between the S roller group 12 and the conveying roller 14, the tension stretching roller group 16 includes a plurality of rollers 161, the cooling system 50 includes a plurality of rollers 51, 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com