Control system and method for cold energy utilization in LNG gasification process

A control method and control system technology, applied in the field of LNG cold energy utilization, can solve problems such as impossible dispersion, complex control of LNG gasification cold energy utilization, and influence on LNG cold energy utilization, so as to achieve low cooling range and avoid untimely Control and reduce the effect of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

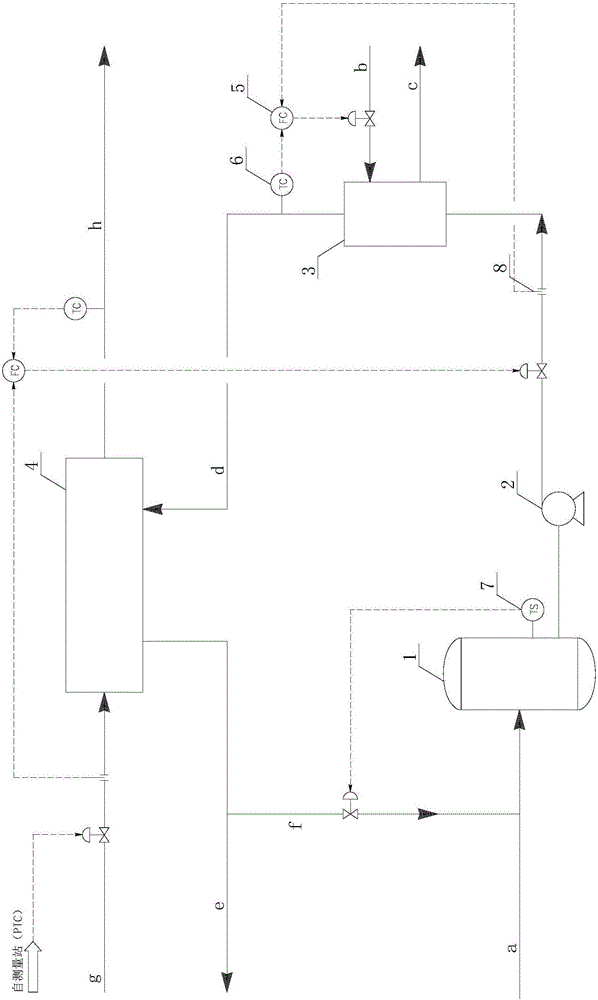

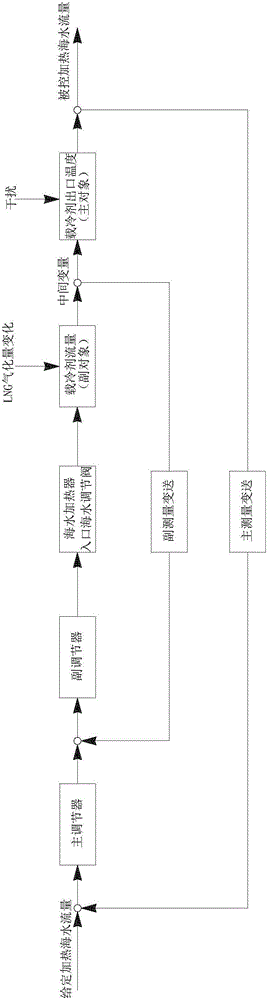

[0055] Take a gasification station with an LNG gasification capacity of 300t / h as an example. The gasification station gasifies -145°C natural gas and heats it up to 2°C, and then merges it into the municipal gas pipeline network. The brine is transported to the downstream cold energy user. The temperature requirement of the brine is -35°C. After releasing the cold energy, the brine returns to a temperature of -5°C. After heating, it enters the LNG vaporizer 4 at a temperature of 10°C. The secondary refrigerant is 30% calcium chloride solution. Sea water temperature is 15°C.

[0056] The brine is returned from the cold energy user to the brine storage tank 1, and the natural gas temperature at the natural gas outlet of the LNG vaporizer 4 is interlocked with the regulating valve at the outlet of the brine delivery pump 2 to control the calcium chloride solution entering the LNG gasification The flow rate of device 4 is 1703t / h.

Embodiment 2

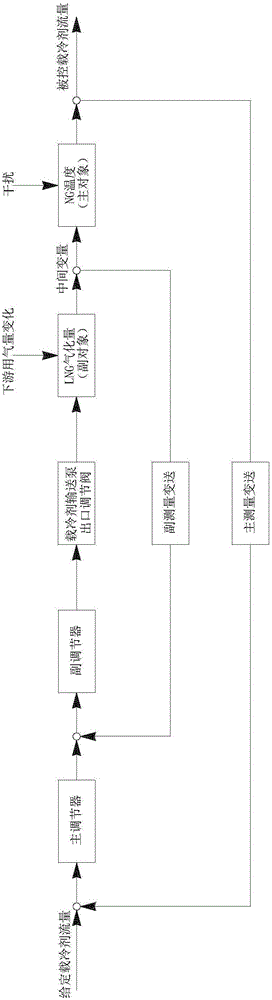

[0061] On the basis of the working conditions of Example 1, the gasification capacity of LNG is adjusted to 200t / h after the demand of natural gas users decreases. When the flow rate of the brine entering the LNG vaporizer 4 is not adjusted, the temperature of the natural gas at the outlet of the LNG vaporizer 4 rises. If a single-loop interlock control is used, the response is slow and the fluctuation is large. The temperature at which LNG enters the LNG gasifier 4 is fixed to the outlet temperature of natural gas and the temperature of the brine, and the flow of brine is proportional to the flow of natural gas, and the cascade control system provided in the present invention can be used. When the natural gas flow rate at the inlet of the LNG gasifier 4 changes to 200t / h, the interlocking (secondary circuit) between the LNG inlet flow rate and the brine delivery pump 2 outlet flow rate will adjust the brine flow rate to 1135t / h, and then the natural gas outlet temperature will...

Embodiment 3

[0064] On the basis of the working conditions of Example 1, the demand of natural gas users decreases, and the gasification capacity of LNG is adjusted to 100t / h. When the cold energy provided by the refrigerant cannot meet the cooling demand, the cold energy user decides to use the backup electric compression refrigeration system, the refrigerant storage system and the ice storage system for peak regulation.

[0065] Calcium chloride solution returns to the refrigerant storage tank 1 after long-distance transportation and the temperature rises to 12°C. The temperature in the storage tank is interlocked to open the refrigerant return line valve to control the temperature in the storage tank to 10°C. The temperature of the natural gas outlet where the calcium chloride solution enters the LNG vaporizer 4 is interlocked with the outlet regulating valve of the brine transfer pump 2 to control the flow rate of the calcium chloride solution into the LNG vaporizer 4 to be 569 t / h. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com