Self-heat recuperation wood drying system and method

A wood drying and self-regenerating technology, applied in wood drying, heating to dry solid materials, drying solid materials, etc., can solve the problems of energy waste, low humid air temperature, inability to effectively recover drying medium and water vapor, etc. The effect of low energy consumption and increased speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

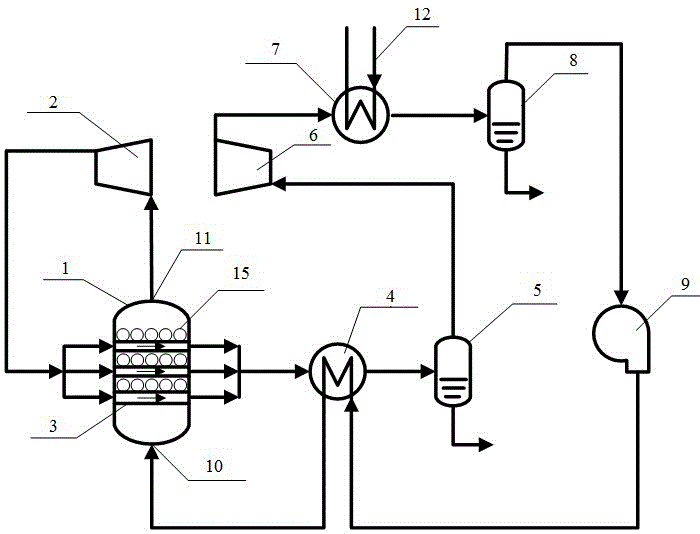

[0015] Refer below figure 1 Describe the working process of the self-regenerating wood drying system.

[0016] Firstly, the dry air enters the drying tank through the drying air inlet 10 at the bottom of the drying tank 1 after being preheated by the heat exchanger 4. In the drying tank, the drying air exchanges heat with the heating coil 3 while exchanging heat with wood to provide the heat needed for water evaporation. The humid air coming out of the dry air outlet 11 on the top of the drying tank enters the compressor 2 to be compressed and then enters the heating coil 3 to release heat, then enters the heat exchanger 4 to preheat the dry air, and then passes through the first gas-liquid separator 5 to separate the moisture and then enters The expander 6 works, and recovers part of the expansion work. The expanded air enters the condenser 7 and is cooled by the cooling medium 12, and then enters the second gas-liquid separator 8 to separate moisture. The air from the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com