Timing belt durability tester and timing belt durability testing method

A technology for durability testing and timing belts, which is applied in the testing of mechanical components, testing of machine/structural components, testing of machine gears/transmission mechanisms, etc. It can solve the problems of belt pulley application, reliability discount of durability test results, and non-existence. , to achieve the effects of low power consumption, energy saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

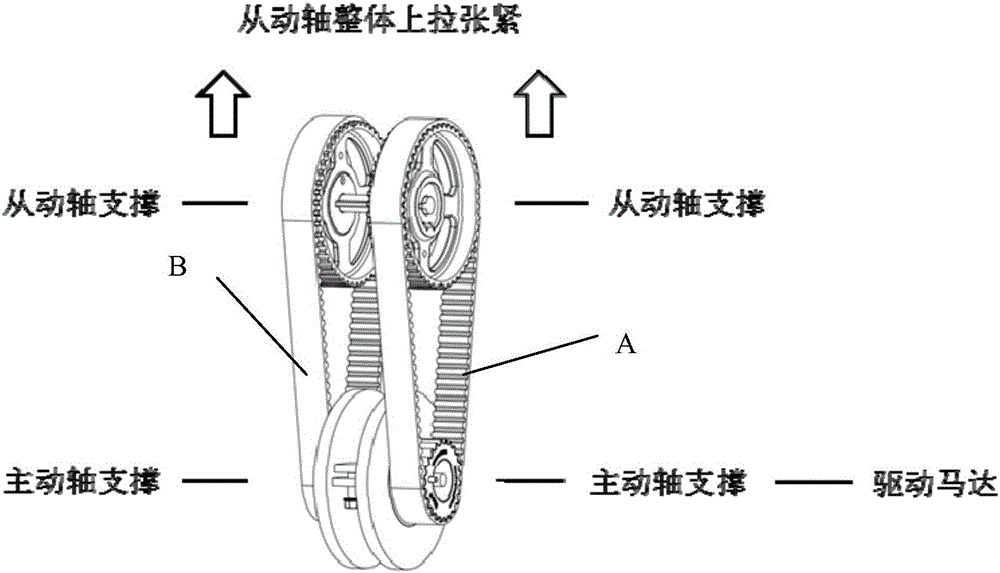

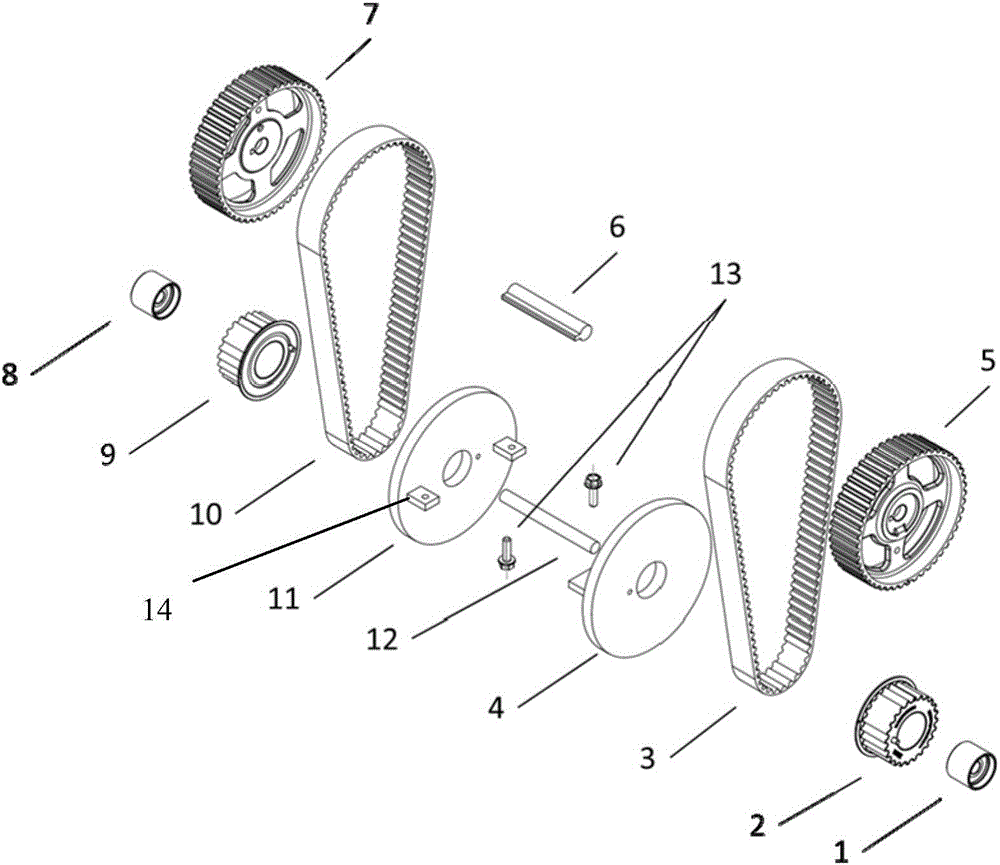

[0033] As mentioned in the background technology section, the traditional belt durability testing machine generally uses a modified engine, which has the disadvantages of low durability test flexibility, high cost of the testing machine, and waste of electric energy. The timing belt durability test not installed on the engine body is generally tested in the way of no gear train load. Because this method cannot apply the load in actual use to the pulley, the measured belt does not have the characteristics of different tensions of the loose side and the tight side under actual working conditions, and the reliability of the durability test results is greatly reduced.

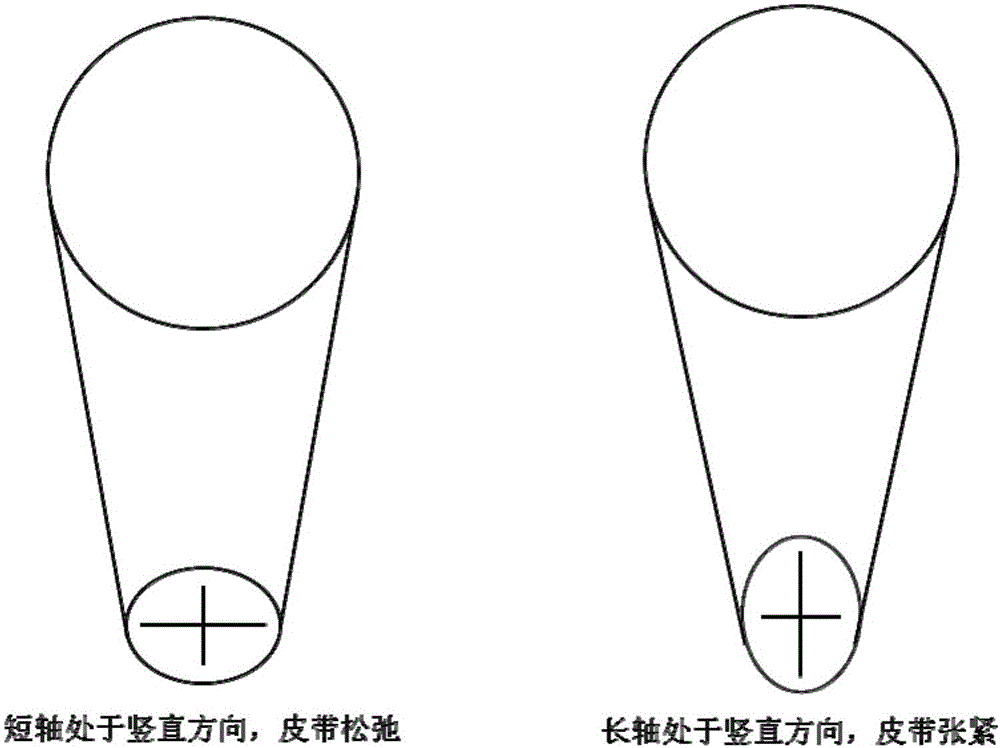

[0034] Aiming at the deficiencies in the prior art, the present invention provides a timing belt durability testing machine, which uses a mechanical principle to form a rotation angle difference in the wheel train, so that the timing toothed belt can realize and maintain the tension of the elastic side on the durabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com