Testing system considering THMC coupling effect in rock joint shearing process

A technology of shearing process and test system, which is applied in the field of geotechnical engineering, can solve the problems of inability to realize test and analysis, bear low seepage pressure, bear high seepage pressure, etc., and achieve long-term loading test, facilitate accurate analysis, and good sealing performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

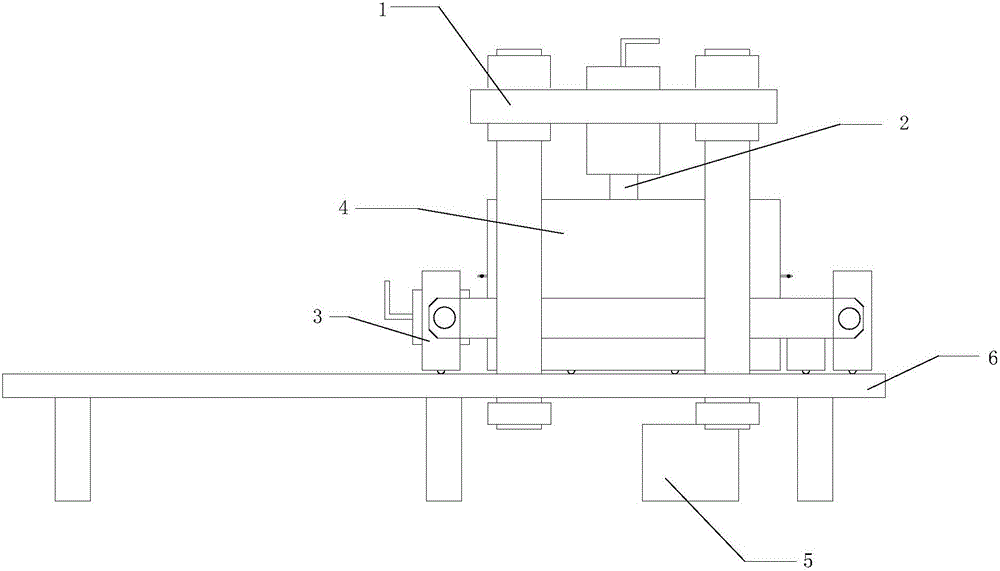

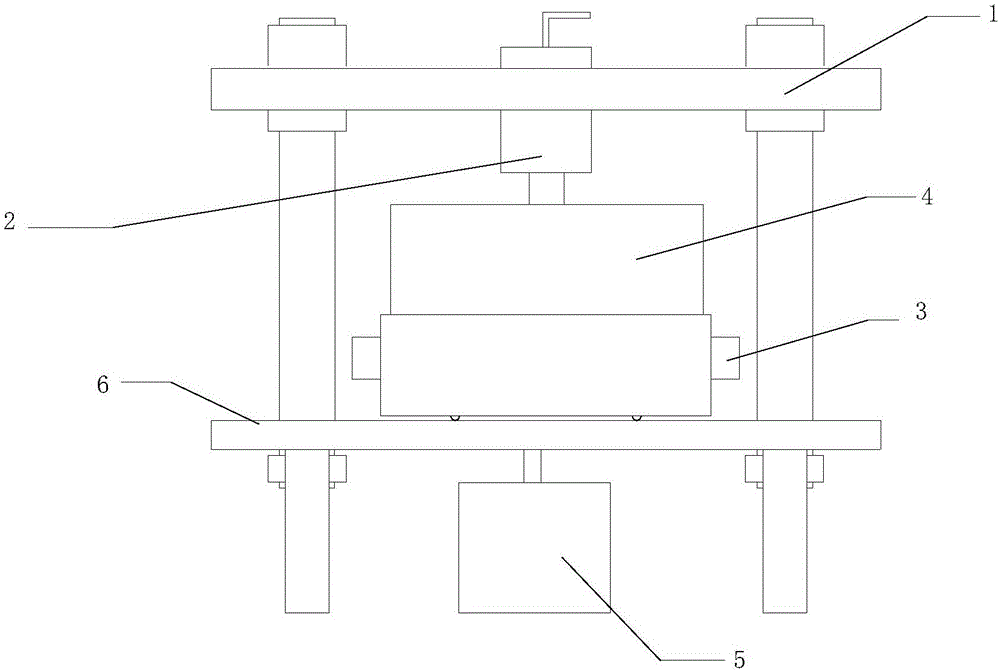

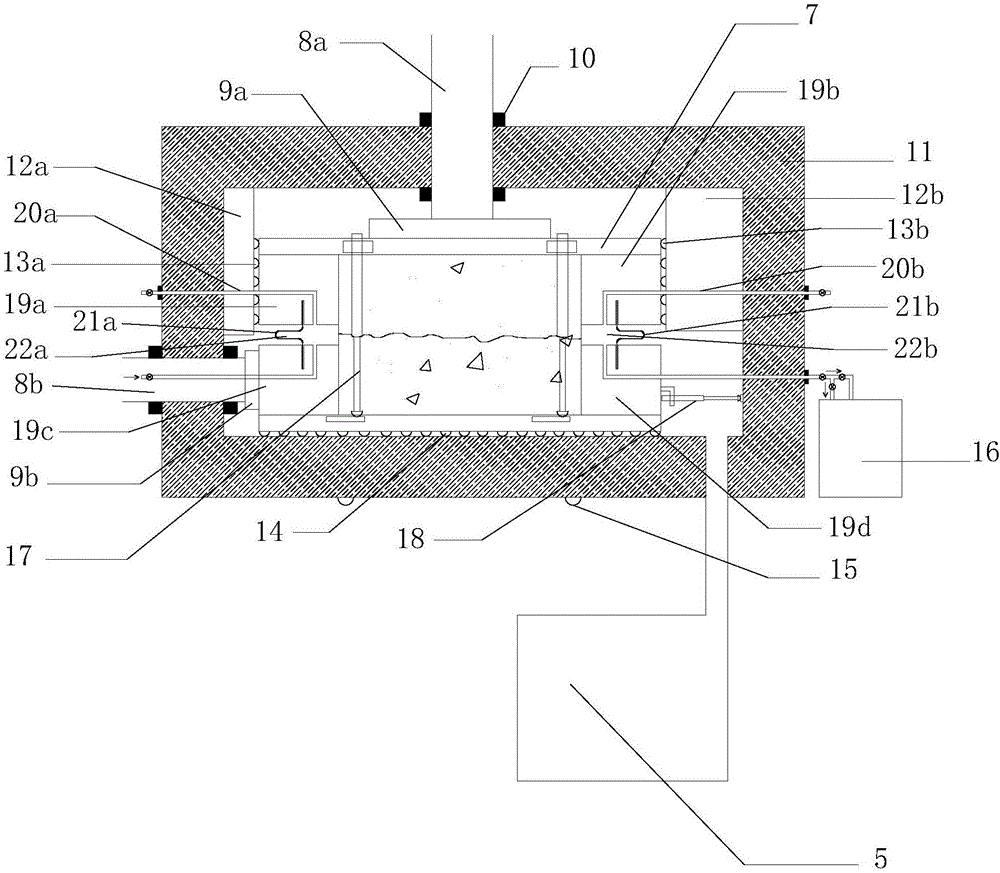

[0034] refer to Figure 1 to Figure 5 , a test system considering the THMC coupling effect in the rock joint shearing process, including a main engine and a loading structure, a loading servo control system, a seepage shear box and a sealing device, a high and low temperature environmental test chamber and a seepage servo control system, the main engine And the loading structure includes a normal loading frame 2 and a horizontal loading frame 3 with independent loading capacity perpendicular to each other, the normal loading frame is a mechanism for loading a normal force to the specimen, and the horizontal loading frame is for A mechanism for loading a shear force on a specimen; the loading servo control system is used for a hydraulic loading servo control system for ordinary tests and a motor servo loading system for rheological tests;

[0035] The seepage shear box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com