High-square-resistance safety film having horizontal spacing bars for isolation

A technology of gap strips and safety films, which is applied to parts of fixed capacitors, electrodes of fixed capacitors, and wire-wound capacitors. Increased field strength, reduced capacity loss, and eliminated heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

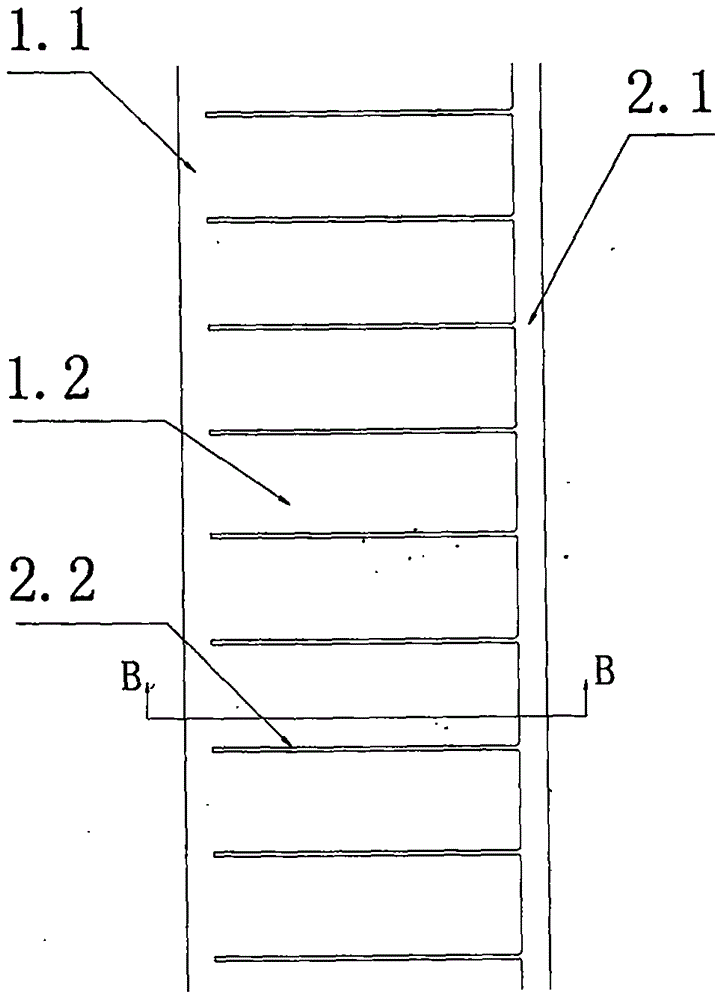

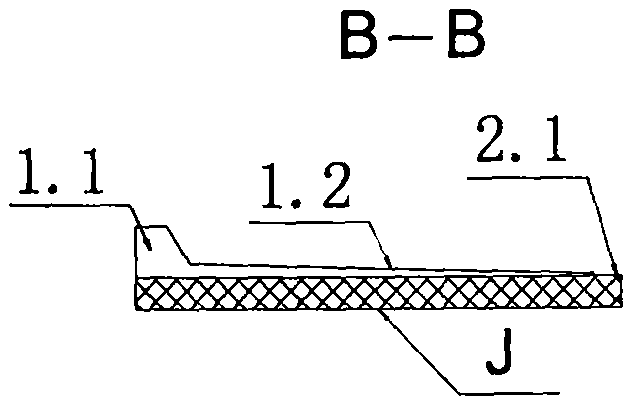

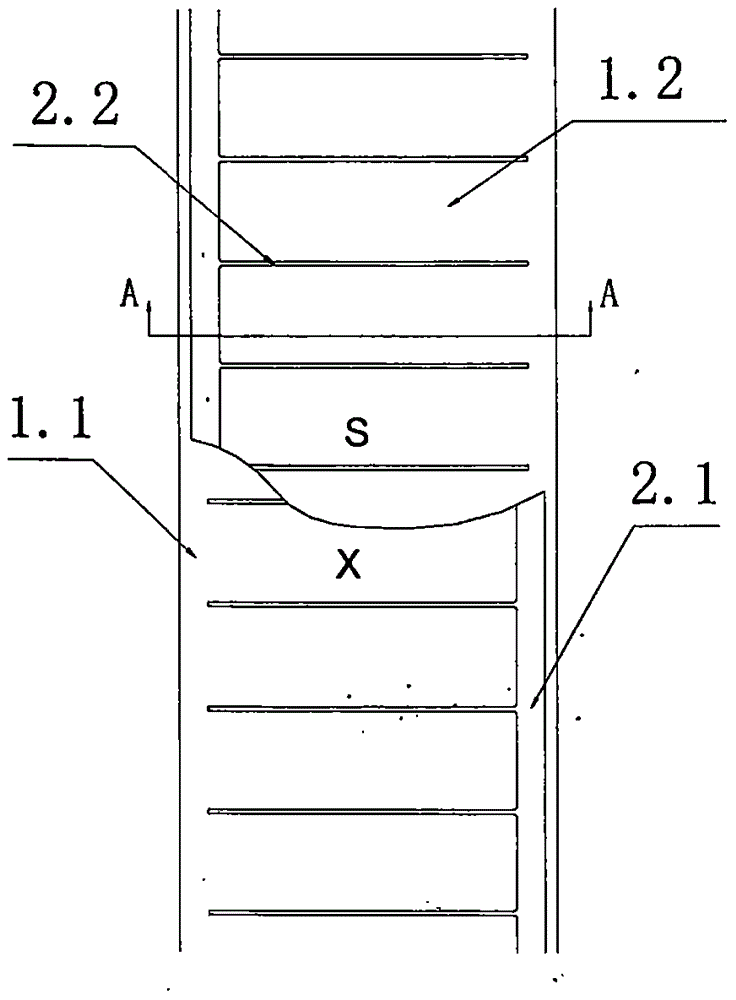

[0026]The embodiment is to form a composite film strip by evaporating zinc / aluminum metal electrode coating on the polypropylene dielectric material base film J having a width of 60mm. One side of the composite film strip is a margin of 2.1, and the width is 2.5mm; The side is the thickened side of the coating 1.1, and the width is 2.2mm; on the metal coating between the left side and the thickened side, there are a plurality of parallel and equally spaced transverse space strips 2.2 for longitudinal isolation; the width of the transverse space strip 2.2 The length is 0.2-0.3mm, and the length is adapted to the width of the film tape, so that one end communicates with the left edge, the other end intersects with the thickened edge 1.1, and the depth of the thickened edge is about 0.8mm; the distance between the transverse gap strip 2.2 is selected as 17 or 34mm ( should be the approximate number of the outer circumference of the embossing roller for evaporation), and the angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com