PCB (Printed Circuit Board) chip structure

A chip structure and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of insufficient space for heat sinks, cost increase, insertion, etc., to improve product reliability, simple manufacturing process, and reduce chips. The effect of junction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Making and installing a PCB chip with good heat dissipation function

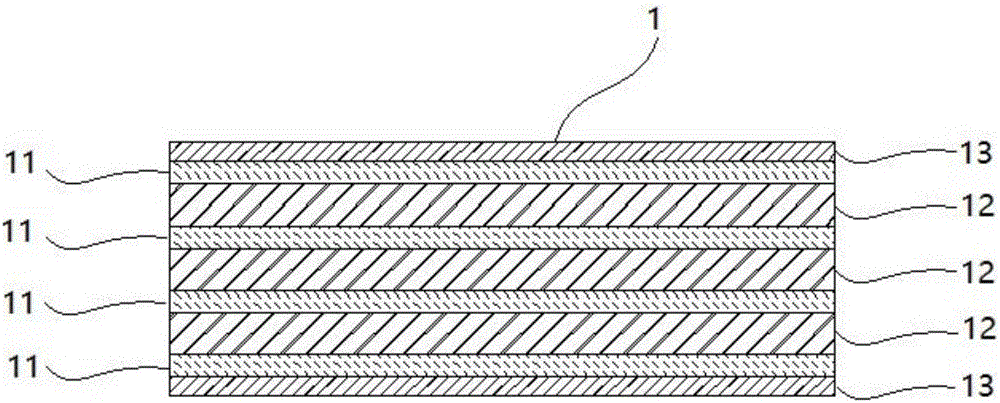

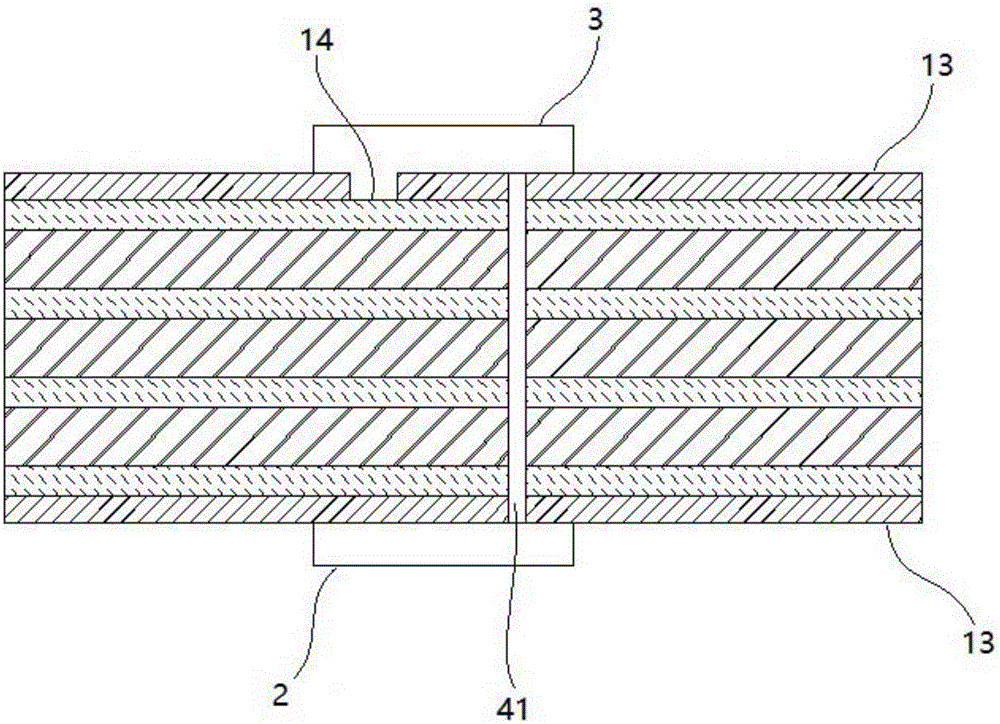

[0048] 101: Make PCB 1: use 4 layers of copper foil 11, and the base material 12 between each adjacent two layers of copper foil 11 (a total of 3 layers of base material 12) are laminated to form a composite layer structure, and the copper foil 11 on the surface of the composite layer The signal line is depicted on the top; a layer of green oil covering layer 13 is covered on the area where the signal line is depicted, and the area where the signal line is not depicted is a copper foil bare area 14, and the copper foil 11 is exposed;

[0049]102: Install chip 2: form a pad corresponding to the pin of chip 2 on one surface of PCB1 through the surface treatment process, and bond the pin of chip 2 to the pad, so that chip 2 is mounted on the surface of PCB1 ;

[0050] 103: Spraying graphite 3: Spray a layer of graphite 3 on the corresponding area of the other side of the PCB1 opposite t...

Embodiment 2

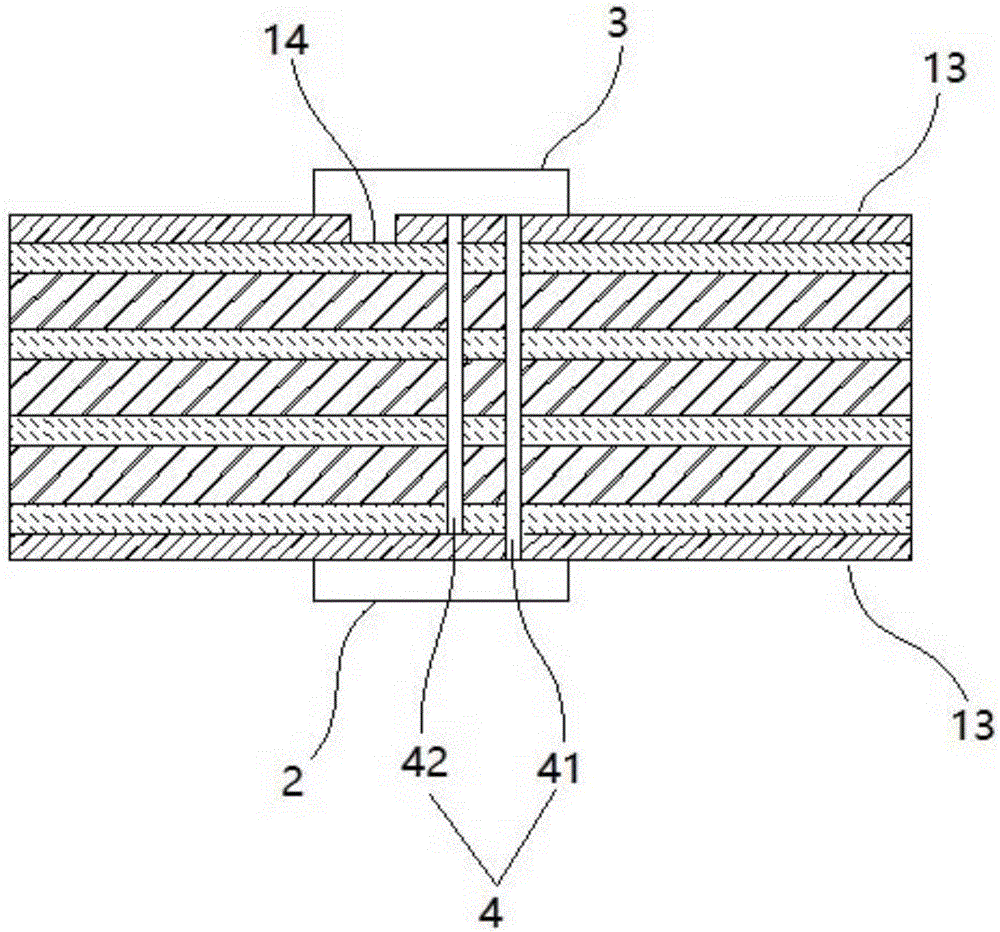

[0052] Embodiment 2: Making and installing a PCB chip with good heat dissipation function

[0053] 201: Make PCB1: use 4 layers of copper foil 11, and the base material 12 between each adjacent two layers of copper foil 11 (a total of 3 layers of base material 12) are laminated to form a composite layer structure, and the outermost copper foil of the composite layer Signal lines are depicted on 11; a layer of green oil covering layer 13 is covered on the area where the signal lines are depicted, and the copper foil bare area 14 is not depicted with signal lines, and the copper foil 11 is exposed;

[0054] 202: Install chip 2: form a pad corresponding to the pin of chip 2 on one surface of PCB1 through the surface treatment process, and bond the pin of chip 2 to the pad, so that chip 2 is mounted on the surface of PCB1 ;

[0055] 203: Spraying graphite 3: using carbon technology, spray a layer of graphite 3 on the corresponding area on the other side of PCB1 opposite to the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com