A kind of preparation method of long-life lead-acid battery positive plate

A lead-acid battery, positive plate technology, applied to lead-acid battery electrodes and other directions, can solve the problems of short service life, softening and falling off of positive lead paste, etc., and achieves the effect of long service life, large initial capacity, and guaranteed stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

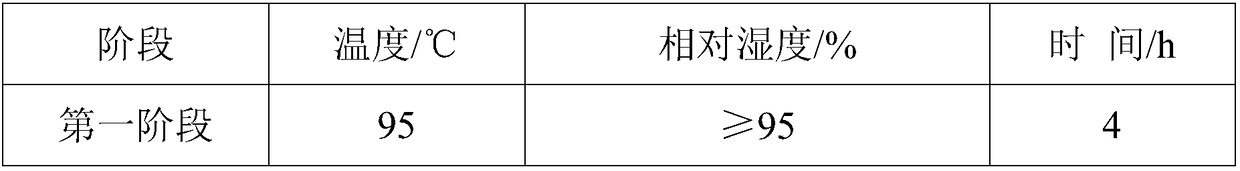

[0029] In this embodiment, the lead oxide content is 75% and the tap density is 2.5g / cm. 3 100kg of lead powder for battery production, sodium perborate monohydrate (NaBO 3 ·H 2 0) 0.1kg, 0.08kg of special polyester staple fiber for battery, 1.0kg of ultrafine tetrabasic lead sulfate additive with average particle size of 2 microns, added in the paste machine and stirred and mixed for 2min; added 9kg of pure water, stirred and oxidized for 10min. Add density of 1.40g / cm during stirring 3 H 2 SO 4 The aqueous solution is 14kg, the time of the addition process is controlled at 10min, and the temperature of the pre-mixture of the lead paste during the addition process is controlled below 65°C. Continue stirring until the temperature drops to 53°C, stop stirring, and complete the paste to obtain lead paste; then fill the lead paste on the grid to make an uncured positive plate; finally, send the uncured positive plate into the In the curing chamber, curing is performed in the...

Embodiment 2

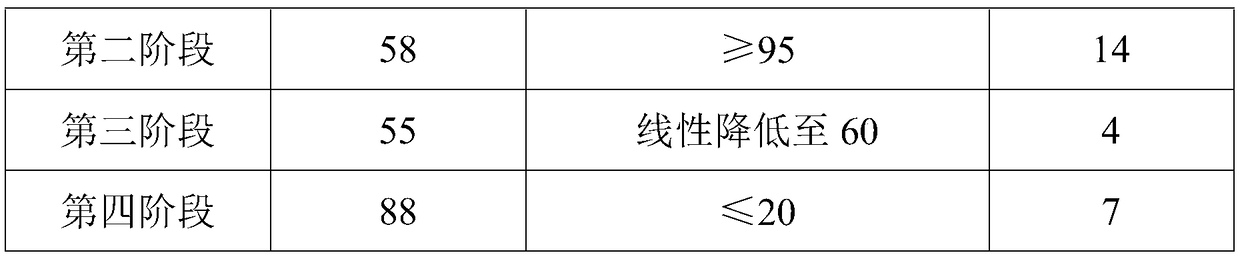

[0033] In this embodiment, the lead oxide content is 80% and the tap density is 2.2g / cm. 3 100kg of lead powder for battery production, sodium perborate tetrahydrate (NaBO 3 ·4H 2 0) 0.4kg, 0.1kg of special polyester staple fiber for battery, 1.0kg of ultrafine tetrabasic lead sulfate additive with an average particle size of 4 microns, add in the paste machine and stir and mix for 1min; add 8kg of pure water, stir and oxidize for 15min. Add density of 1.40g / cm during stirring 3 H 2 SO 4 The aqueous solution is 16kg, the time of the addition process is controlled at 12min, and the temperature of the addition process is controlled below 65°C. Continue stirring until the temperature drops to 50°C, stop stirring, and complete the paste to obtain lead paste; then fill the lead paste on the grid to make an uncured positive plate; finally, send the uncured positive plate into the In the curing chamber, curing is performed in the following four stages in sequence:

[0034]

...

Embodiment 3

[0038] In this embodiment, the lead oxide content is 85% and the tap density is 2.7g / cm. 3 100kg of lead powder for battery production, sodium perborate tetrahydrate (NaBO 3 ·4H 2 0) 0.5kg, 0.1kg of special polyester staple fiber for storage battery, 1.0kg of ultrafine tetrabasic lead sulfate additive with an average particle size of 5 microns, added and stirred and mixed in the paste machine for 1min; added 7kg of pure water, stirred and oxidized for 20min. Add density of 1.40g / cm during stirring 3 H 2 SO 4 The aqueous solution is 18kg, the time of the addition process is controlled at 15min, and the temperature of the addition process is controlled below 65°C. Continue stirring until the temperature drops to 47 °C, stop stirring, and complete the paste to obtain lead paste; then fill the lead paste on the grid to make an uncured positive plate; finally, send the uncured positive plate into the In the curing chamber, curing is performed in the following four stages in se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com