Preparation of nano-palladium material by employing polypeptide R5 template method, shape and form control and application in fuel cell

A morphology and template technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unpublished literature or patent reports, and achieve the effects of stable properties, high electron transfer number, and high initial potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

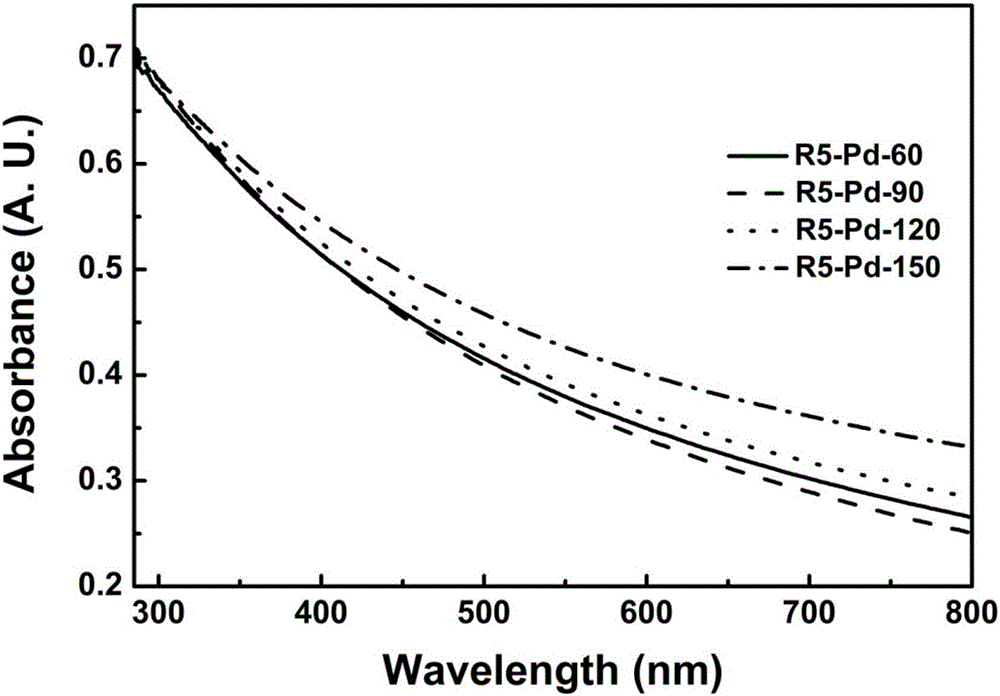

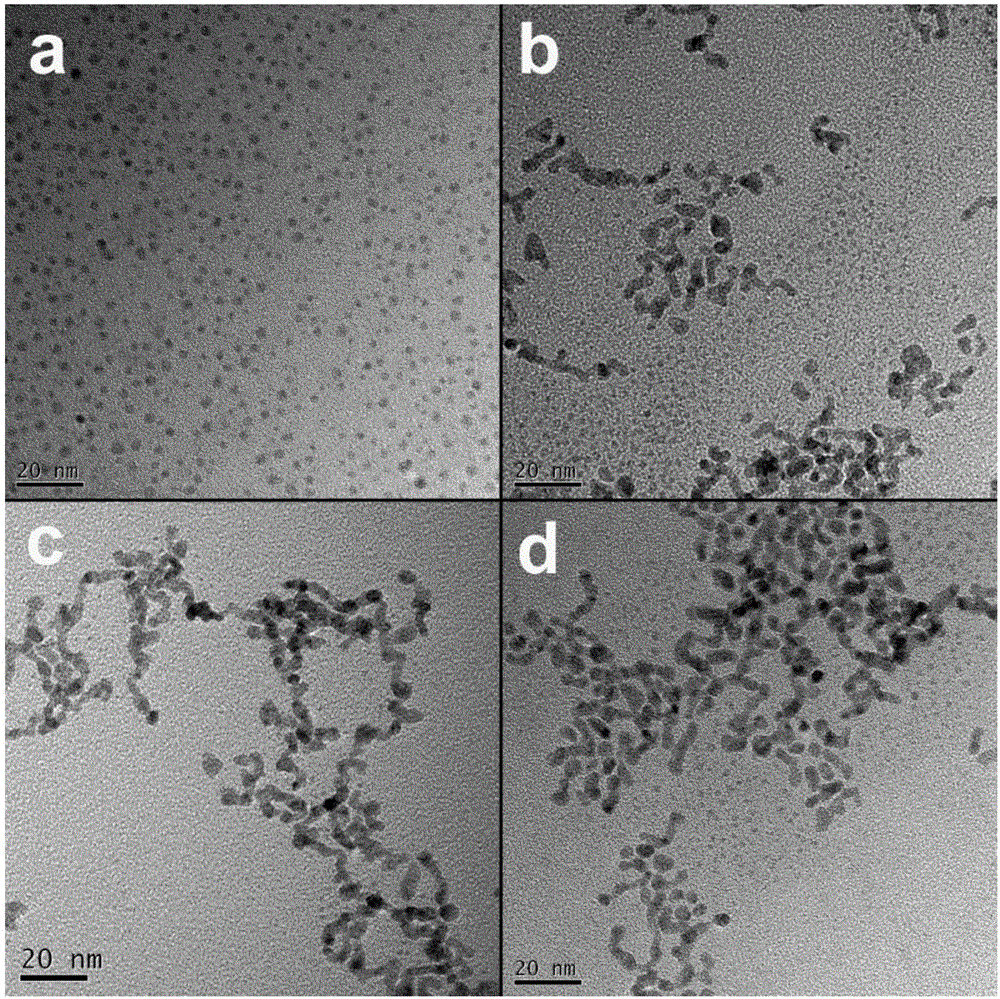

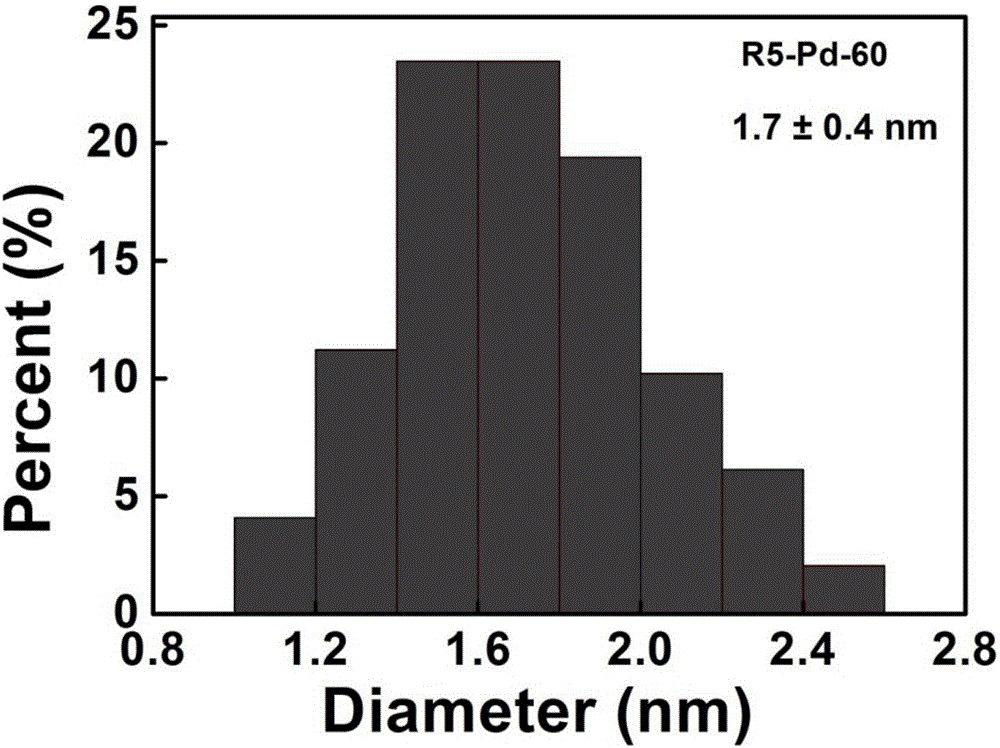

[0034] (1) Dilute 9.86 μL of R5 polypeptide solution (4.97mM) to 1776.72 μL at room temperature according to the molar ratio of polypeptide to palladium element 1:60, add 76.28 μL of potassium chloropalladate solution (38.54mM) and mix, Stir for 15 min at a speed of 300 rpm.

[0035] (2) Add 147 μL of newly prepared sodium borohydride (NaBH 4 ) solution (0.1M) into the mixed solution, and continue magnetic stirring at the original speed for 1 h to obtain the polypeptide palladium nanocatalyst.

[0036] Catalytic performance test:

[0037] The electrochemical test and characterization was carried out in a test cell with a three-electrode system on a CHI 750E electrochemical workstation produced by Shanghai Chenhua Company. Among them, the platinum wire is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the glassy carbon electrode loaded with the catalyst is the working electrode. Add 24.78 μL of aqueous catalyst solution dropwise on the surface o...

Embodiment 2

[0044] (1) According to the molar ratio of polypeptide to palladium element 1:90, dilute 6.57 μL of R5 polypeptide solution (4.97mM) to 1776.72 μL at room temperature, add 76.28 μL of potassium chloropalladate solution (38.54mM) and mix, in Stir for 15 min at a speed of 300 rpm.

[0045] (2) Add 147 μL of newly prepared sodium borohydride (NaBH 4 ) solution (0.1M) into the mixed solution, and continue magnetic stirring at the original speed for 1 h to obtain the polypeptide palladium nanocatalyst.

[0046] Catalytic performance test:

[0047] The electrochemical test and characterization was carried out in a test cell with a three-electrode system on a CHI 750E electrochemical workstation produced by Shanghai Chenhua Company. Among them, the platinum wire is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the glassy carbon electrode loaded with the catalyst is the working electrode. Add 25.28 μL of aqueous catalyst solution dropwise on the surfa...

Embodiment 3

[0056] (1) According to the molar ratio of polypeptide to palladium element 1:120, at room temperature, dilute 4.93 μL of R5 polypeptide solution (4.97mM) to 1776.72 μL, add 76.28 μL of potassium chloropalladate solution (38.54mM) and mix, in Stir for 15 min at a speed of 300 rpm.

[0057] (2) Add 147 μL of newly prepared sodium borohydride (NaBH 4 ) solution (0.1M) into the mixed solution, and continue magnetic stirring at the original speed for 1 h to obtain the polypeptide palladium nanocatalyst.

[0058] Catalytic performance test:

[0059] The electrochemical test and characterization was carried out in a test cell with a three-electrode system on a CHI 750E electrochemical workstation produced by Shanghai Chenhua Company. Among them, the platinum wire is the counter electrode, the Ag / AgCl electrode is the reference electrode, and the glassy carbon electrode loaded with the catalyst is the working electrode. Add 25.56 μL of aqueous catalyst solution dropwise on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com