Fluorine-doped lithium-ion solid electrolyte and preparation method thereof

A solid electrolyte, lithium ion technology, used in circuits, electrical components, secondary batteries, etc., can solve the problem of low lithium ion conductivity, and achieve the effect of improving the migration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

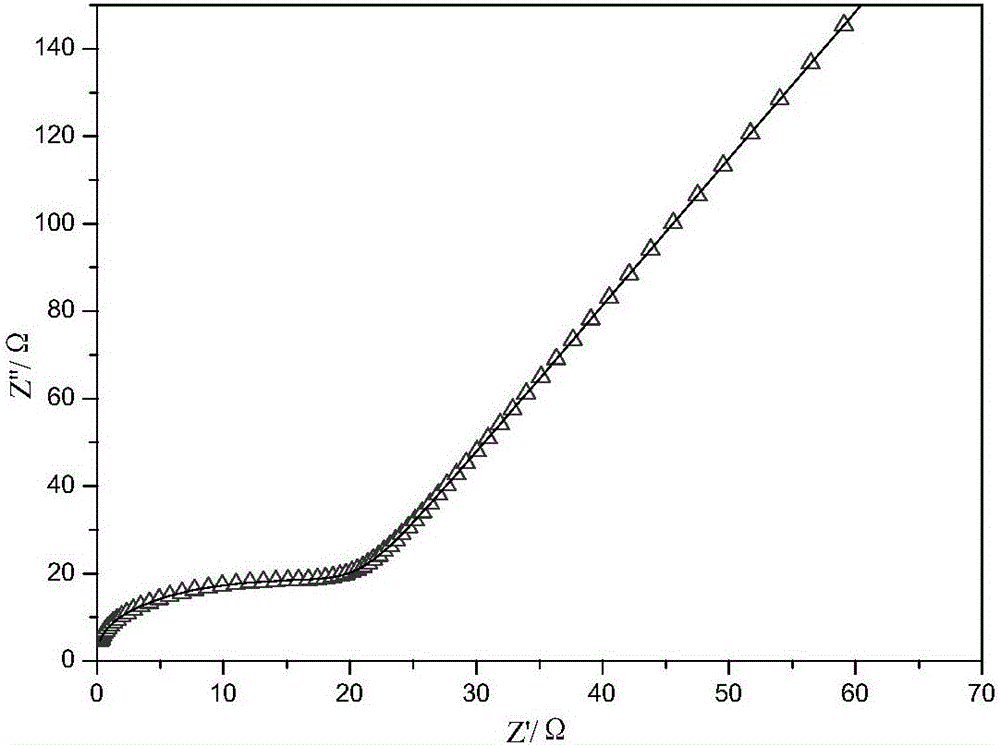

[0021] Embodiment 1: In this technical scheme, Li 2 S: GeS 2 :P 2 S 5 : LiF is uniformly mixed according to the ratio of 4.95: 1.1: 0.95: 0.1 (molar ratio), the mixed raw materials are put into a ball mill jar, and under the protection of an argon atmosphere, ball mill at a speed of 500 rpm for 10 hours. The powder after ball milling is pressed into electrolyte sheets under a pressure of 200Mpa, and the electrolyte sheets are placed in a vacuum atmosphere tube furnace, heated to 600°C at a rate of 2°C / min in an argon atmosphere, and kept at 600°C 10h sintered into a dense solid electrolyte sample sheet. Such as figure 1 is composed of Li 10 Ge 1.1 P 1.9 S 11.9 f 0.1 , the AC impedance diagram of the solid electrolyte sheet under the electrochemical workstation, and the conductivity calculated from the diagram is 2.3×10 -2 S / cm.

Embodiment 2

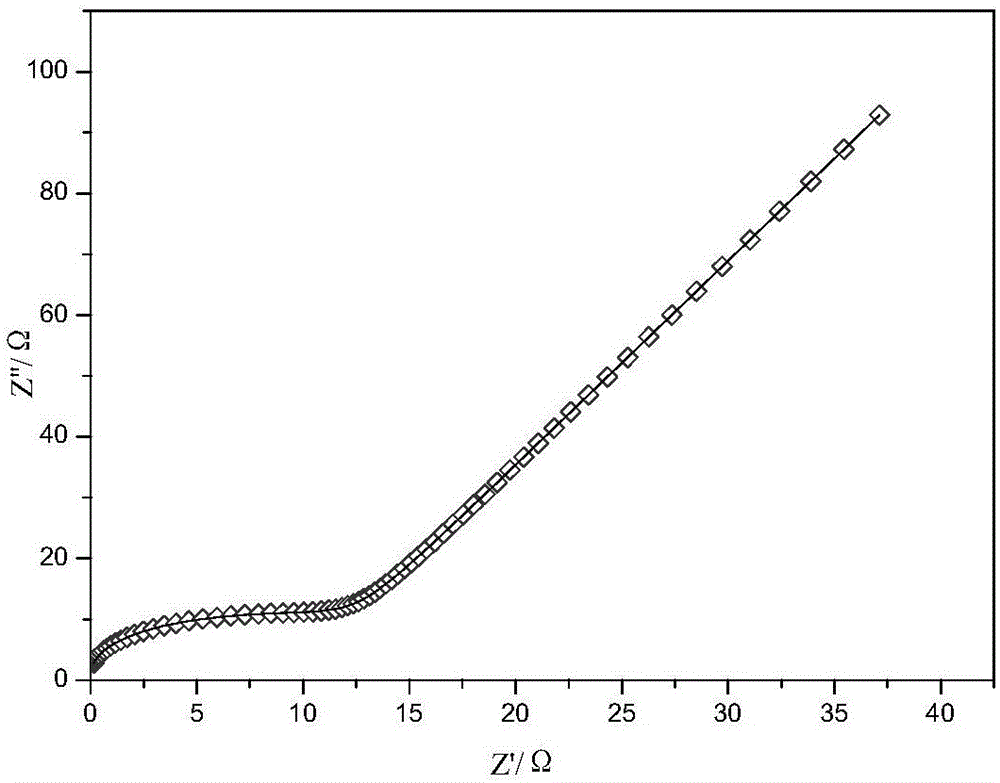

[0022] Embodiment 2: Li 2 S: SnS 2 :P 2 S 5 : LiF is evenly mixed according to the ratio of 4.85: 1.1: 0.95: 0.2 (molar ratio), the mixed raw materials are put into a ball mill jar, and under the protection of an argon atmosphere, ball mill at a speed of 350 rpm for 24 hours. The powder after ball milling is pressed into electrolyte sheets under a pressure of 150Mpa, and the electrolyte sheets are placed in a vacuum atmosphere tube furnace, heated to 650°C at a rate of 3°C / min under an argon atmosphere, and kept at 650°C 8h sintered into a dense solid electrolyte sample sheet. Such as figure 2 is composed of Li 9.9 sn 1.1 P 1.9 S 11.8 f 0.2 , the AC impedance diagram of the solid electrolyte sheet under the electrochemical workstation, and the conductivity calculated from the diagram is 2.8×10 -2 S / cm.

Embodiment 3

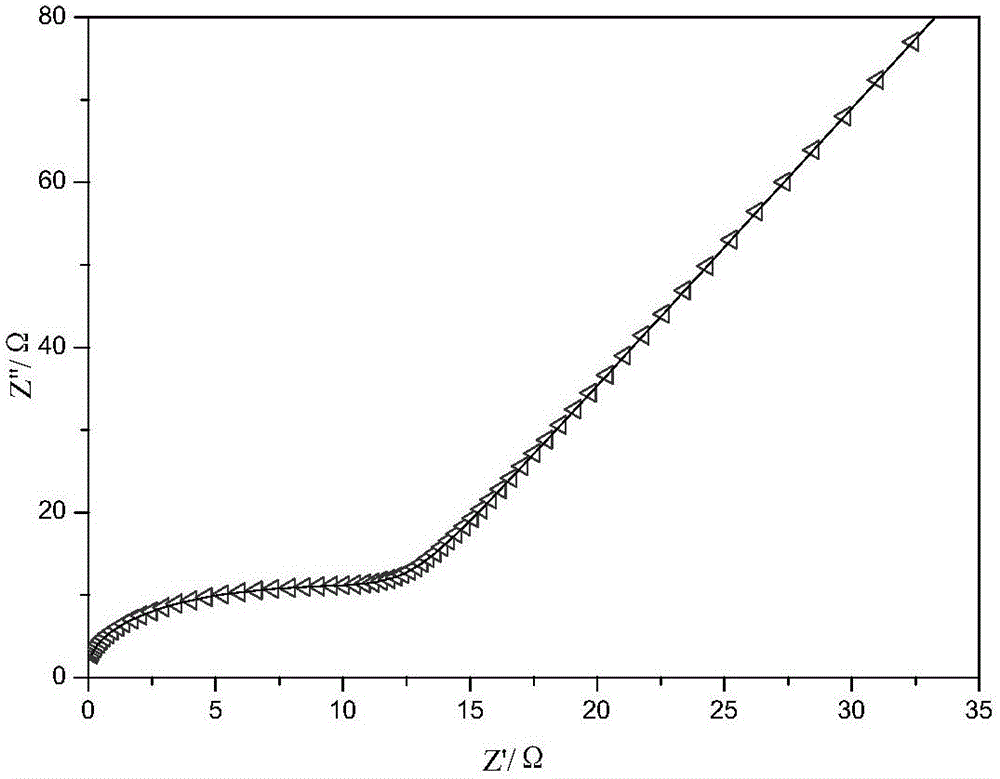

[0023] Embodiment 3: with Li 2 S: SiS 2 :P 2 S 5 : LiF is evenly mixed according to the ratio of 4.75: 1.1: 0.95: 0.3 (molar ratio), the mixed raw materials are put into a ball mill jar, and under the protection of an argon atmosphere, ball mill at a speed of 300 rpm for 25 hours. The powder after ball milling is pressed into electrolyte sheets under a pressure of 100Mpa, and the electrolyte sheets are placed in a vacuum atmosphere tube furnace, heated to 550°C at a rate of 2°C / min in an argon atmosphere, and kept at 550°C 30h sintered into a dense solid electrolyte sample sheet. Such as image 3 is composed of Li 9.8 Si 1.1 P 1.9 S 11.7 f 0.3 , the AC impedance diagram of the solid electrolyte sheet under the electrochemical workstation, and the conductivity calculated from the diagram is 2.9×10 -2 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com