EKF-based rotating speed control method of sensorless ultra-high speed permanent magnet synchronous motor

A permanent magnet synchronous motor, speed control technology, applied in motor generator control, AC motor control, electronic commutation motor control and other directions, can solve problems such as large jitter error, tracking failure, large amount of calculation, etc. Accuracy, improved adaptability, improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

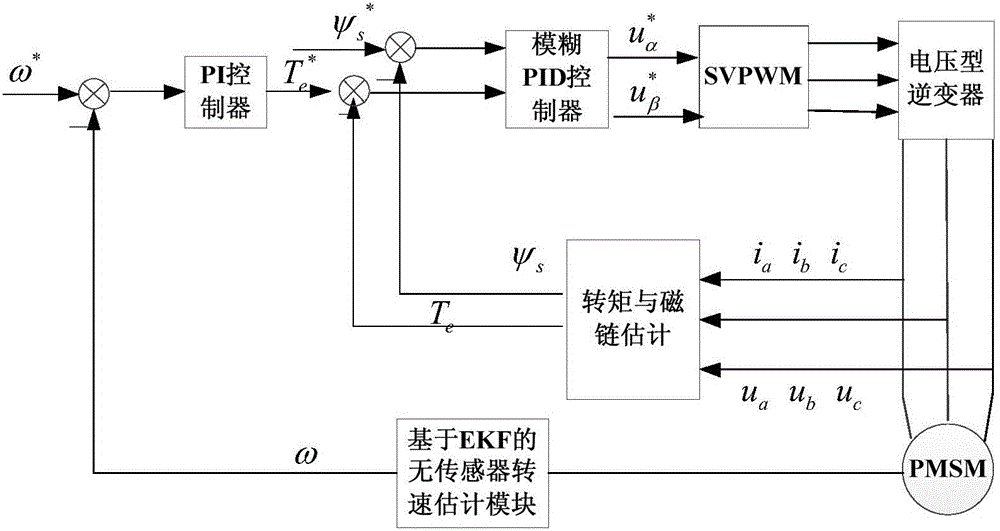

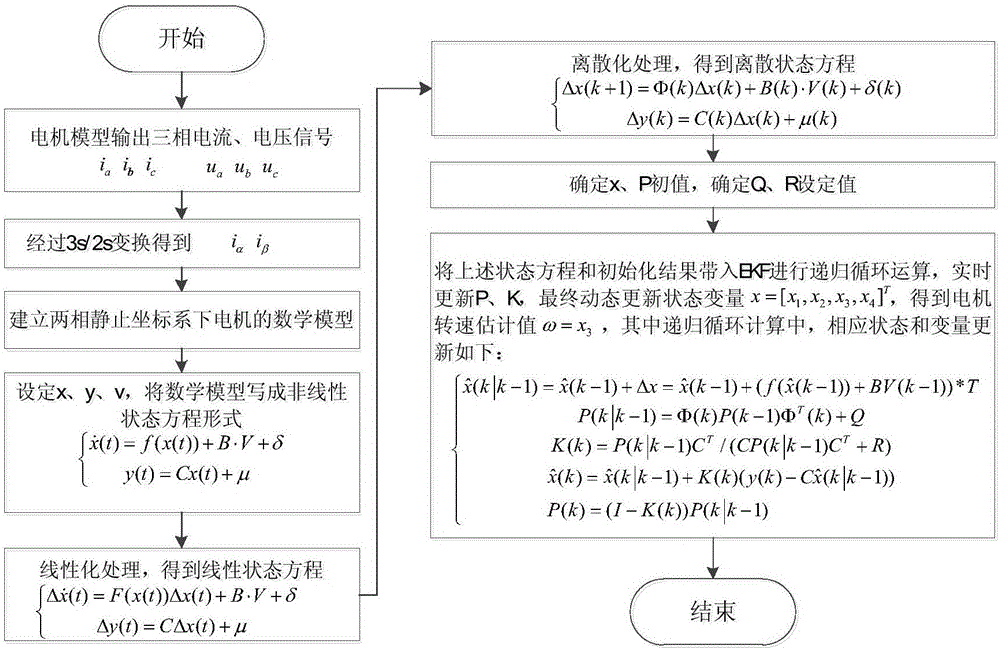

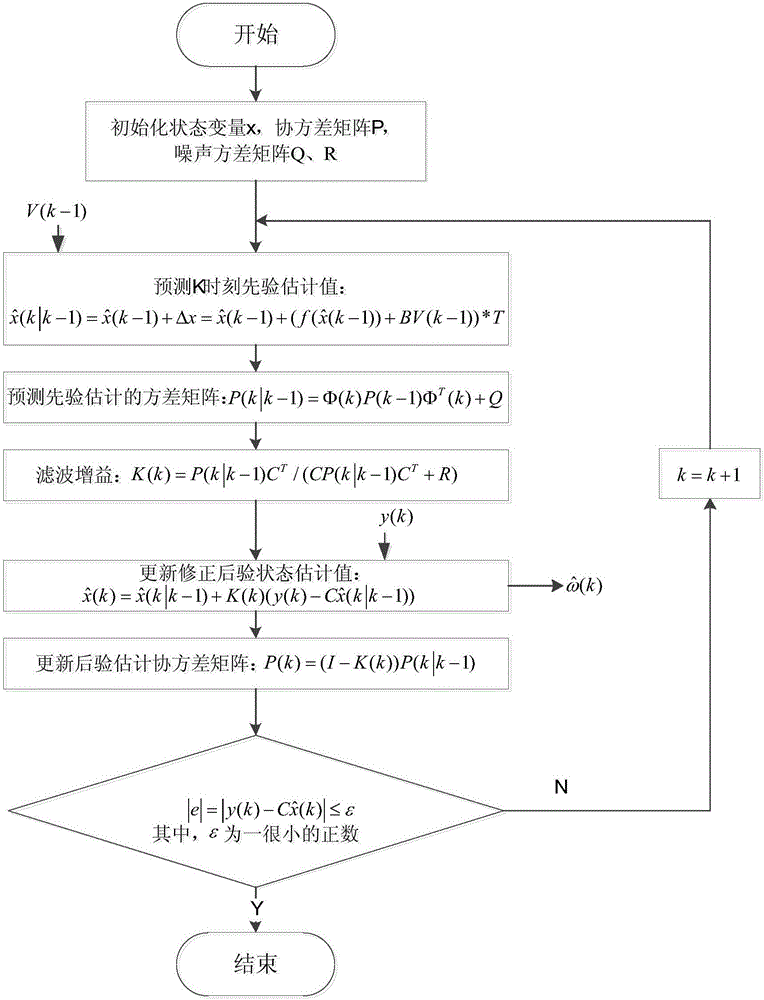

[0017] The EKF-based sensorless ultra-high-speed permanent magnet synchronous motor speed control method of the present invention is applied to the SVPWM-based ultra-high-speed permanent magnet synchronous motor direct torque control system. On the basis of direct torque control, the fuzzy PID controller is used to improve the system self- Adaptability, using the sensorless ultra-high-speed permanent magnet synchronous motor speed estimation algorithm based on EKF, so that the motor speed can be estimated in real time during the dynamic operation of the motor, which has strong robustness and can accurately estimate the motor speed for closed-loop Feedback, and finally realize the stable control of the motor speed.

[0018] combine figure 1 , a kind of sensorless ultra-high speed permanent magnet synchronous motor speed control method based on EKF of the present invention, comprises the following steps:

[0019] Step 1. According to the motor three-phase current i a i b i c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inductance | aaaaa | aaaaa |

| Damping coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com