Antimicrobial agent screening method

A technology for antimicrobials, screening methods, applied in the direction of microorganism-based methods, microorganisms, microorganisms, etc., can solve the problem of removing evaporator cores, mold and bacteria unpleasant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] Example 1: Screening for dominant microorganisms that cause bad odors

[0069] 1. Preparation of old cars emitting bad smell and separation of air conditioning system

[0070] In order to identify the cause of bad smell in airtight environment such as vehicle interior, isolated from 10 old cars that gave off bad smell in different seasons (winter: February-March, summer: June-July) Air Conditioning System. Next, samples were taken from evaporator cores on which biofilms of microorganisms that cause bad odors in air conditioning systems were expected to form (Table 1).

[0071] Table 1

[0072]

[0073] 2. Preparation of Evaporator Core Samples

[0074] The evaporator wicks isolated from the bad smelling old cars 1-10 were stored at 4°C and sealed in polyethylene bags until the evaporator wick samples were used. To isolate and cultivate microorganisms, use sterile needle-nose pliers to take 5 g samples from random parts of each evaporator core, including the fro...

Embodiment 2

[0145] Example 2: Evaluation of antimicrobial activity of antimicrobial agents against screened malodorous microorganisms

[0146] 1. Experimental steps

[0147] The antimicrobial activity of the dominant microorganisms screened in Example 1 was evaluated with various commercially available antimicrobial agents. The antimicrobials tested were as follows:

[0148] Antimicrobial Agent A: fabric deodorant available from P&G Korea.

[0149] Antimicrobial Agent B: hand sanitizer purchased from Paru Corporation.

[0150] Antimicrobial C: A mass-produced antimicrobial containing 45-50% methanol, 1-5% chromium sulfate (CAS 10101-53-8), 1-5% bromine and water.

[0151] Antimicrobial agent D: cationic antimicrobial agent (Parkerizing, Japan).

[0152] Antimicrobial Agent E: Isothiazolinone-based antimicrobial agent containing methylisothiazolinone (CAS 26172-55-4), bronopol (CAS 52-51-7) and the like (Parkerizing, Japan).

[0153] Antimicrobial activity was evaluated as follows: ...

Embodiment 3

[0171] Example 3: Evaluation of the odor of evaporator cores freed from odor-causing microorganisms

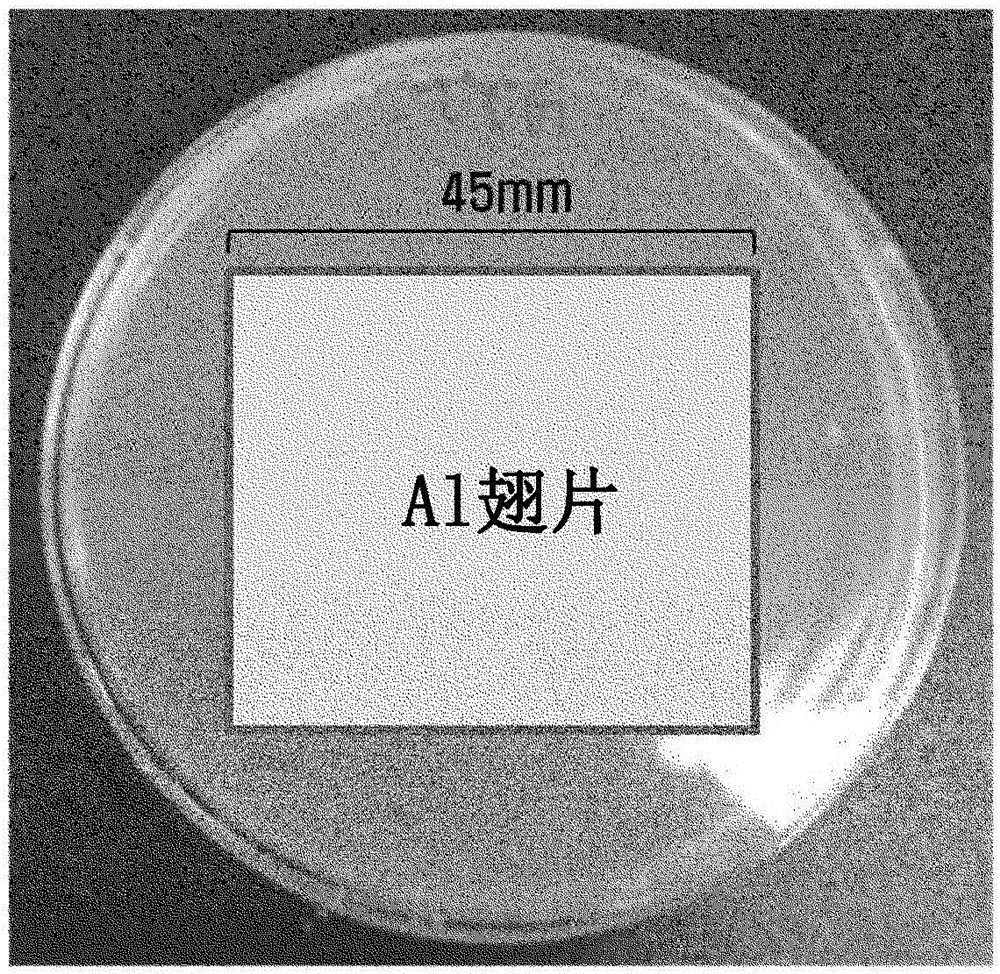

[0172] In order to prepare the evaporator core in which the microorganisms causing bad smell were removed or separated, the odorless microorganisms excluding the microorganisms causing bad smell of Example 1 from the dominant strains inhabiting the evaporator core were combined on the aluminum Culturing was performed on-chip, where aluminum was the material of the evaporator core (Table 10, image 3 ).

[0173] Predominant species that formed colonies on the evaporator core but did not cause an unpleasant odor were selected as odorless microorganisms and cultured as follows.

[0174] 1) Inoculate the isolated odorless microorganisms into liquid R2A medium.

[0175] 2) Cultivate the microorganisms at a temperature of 28°C for 5-7 days.

[0176] 3) Prepare aluminum fins sterilized at 121° C. for 20 minutes under high pressure.

[0177] 4) Uniformly coat the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com