Romidepsin fat microsphere preparation and preparing method thereof

A technology of romidepsin and lipid microspheres, which is applied in the directions of emulsion delivery, freeze-drying delivery, tetrapeptide components, etc., can solve problems such as no reports of romidepsin lipid microsphere preparations, and achieve improved drug safety, Effect of improving compliance and improving targeting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

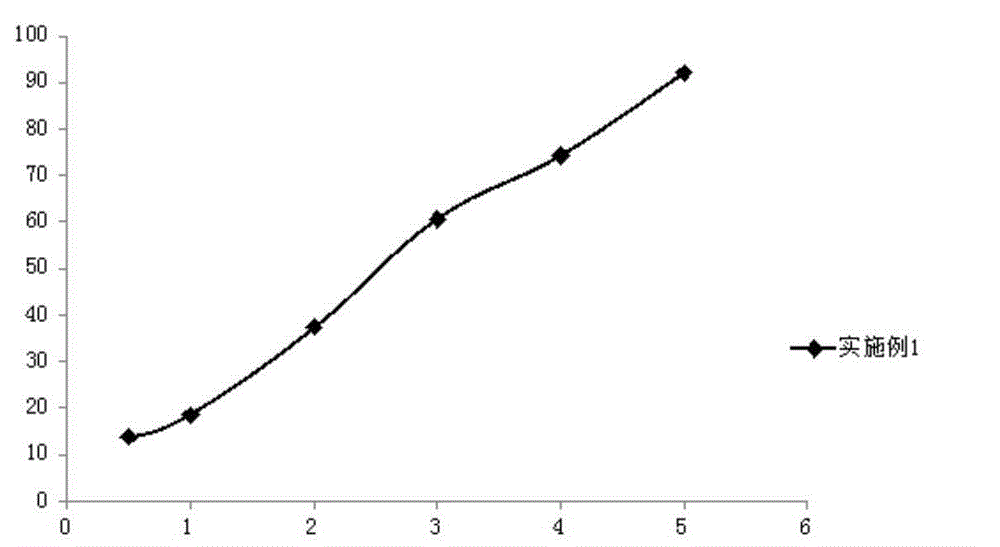

Embodiment 1

[0050] (1) Weigh 1.0g romidepsin, 5.0g soybean oil, 5.0g medium-chain fatty acid triglycerides, 1.5g soybean lecithin, 0.4g propylene glycol and 0.05g ethanol in a beaker, and use a high-speed shearing machine Shear at high speed for 3 minutes, heat and stir in a magnetic stirring water bath at 60°C at a stirring speed of 500rpm to completely dissolve and obtain an oil phase;

[0051] (2) Weigh 0.9g of sodium chloride and place it in a beaker, add 86.2g of water for injection, heat and stir in a magnetic stirring water bath at 60°C, and stir at a stirring speed of 500rpm to completely dissolve it to obtain an aqueous phase;

[0052] (3) under high-speed stirring, the oil phase and the water phase are mixed, and the pH value is adjusted to 7.0 to obtain colostrum;

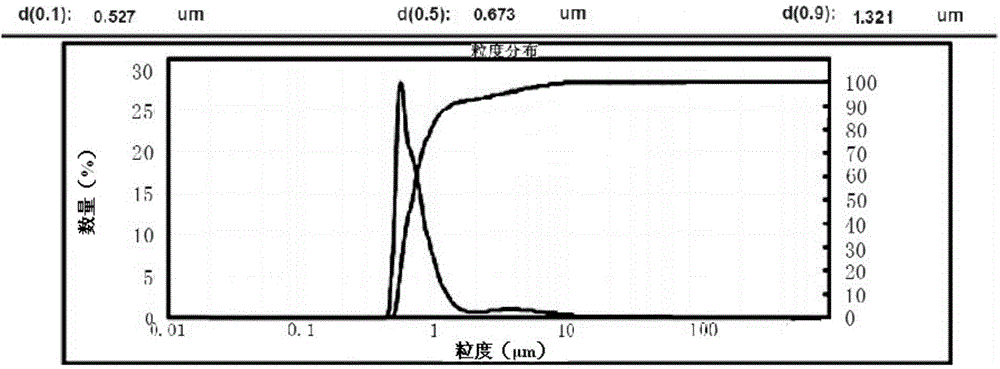

[0053] (4) transfer the colostrum to a high-pressure homogenizer, and use 500bar pressure for high-pressure homogenization to obtain a submicron emulsion;

[0054] (5) Nitrogen-filled sub-package, after autoclaving...

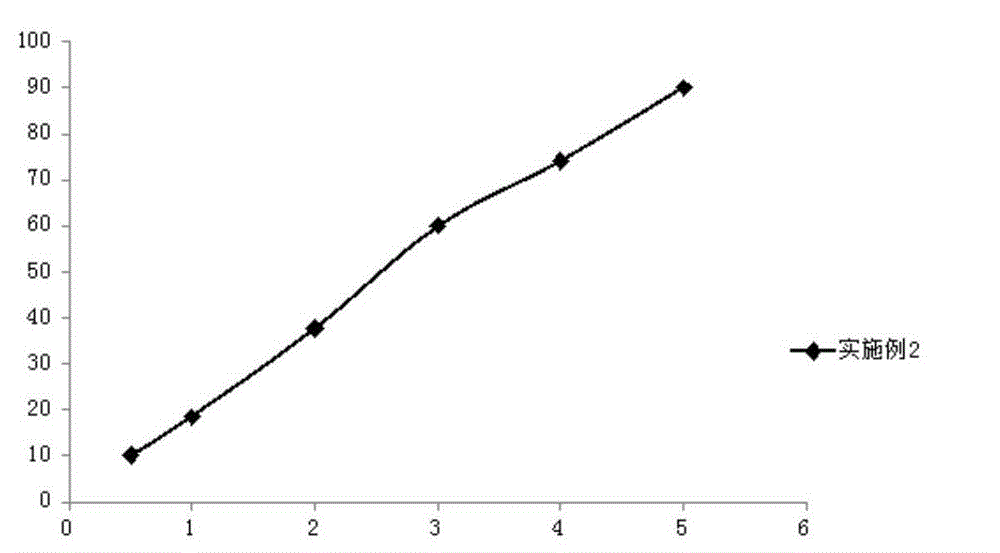

Embodiment 2

[0056] (1) Weigh 1.5g romidepsin, 6.5g soybean oil, 10.5g medium-chain fatty acid triglycerides, 2.0g egg yolk lecithin, 0.8g propylene glycol and 0.2g ethanol in a beaker, and use a high-speed shearing machine Shear at high speed for 5 minutes, heat and stir in a magnetic stirring water bath at 65°C at a stirring speed of 500rpm to completely dissolve it to obtain an oil phase;

[0057] (2) Weigh 0.9g of sodium chloride and put it in a beaker, add 77.4g of water for injection, heat and stir in a magnetic stirring water bath at 65°C, and stir at a speed of 400rpm, so that it is completely dissolved to obtain an aqueous phase;

[0058] (3) under high-speed stirring, the oil phase and the water phase are mixed, and the pH value is adjusted to 7.2 to obtain colostrum;

[0059] (4) transfer the colostrum to a high-pressure homogenizer, and use 350bar pressure for high-pressure homogenization to obtain a submicron emulsion;

Embodiment 3

[0062] (1) Weigh 2.5g romidepsin, 4.5g safflower oil, 15.5g medium-chain fatty acid triglycerides, 2.0g hydrogenated egg yolk lecithin, and 1.0g propylene glycol in a beaker, and use a high-speed shearing machine to perform high-speed shearing. Cut for 8 minutes, heat and stir at 45°C in a magnetic stirring water bath at a stirring speed of 700rpm to completely dissolve and obtain an oil phase;

[0063] (2) Weigh 4.5g of mannitol and place it in a beaker, add 70g of water for injection, heat and stir at 45°C in a magnetic stirring water bath at a stirring speed of 700rpm, and dissolve it completely to obtain an aqueous phase;

[0064] (3) under high-speed stirring, the oil phase and the water phase are mixed, and the pH value is adjusted to 6.7 to obtain colostrum;

[0065] (4) transfer the colostrum to a high-pressure homogenizer, and use 650bar pressure for high-pressure homogenization to obtain a submicron emulsion;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com