Anode plate and wet electric precipitator

A technology of wet electrostatic precipitator and anode plate, which is applied in the direction of external electrostatic separator, electrode structure, electrostatic separation, etc. It can solve the problems of large consumables of dust collecting plate and ineffective use of particle inertial force, etc., so as to improve the effect of dust removal , Guarantee growth, improve the effect of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

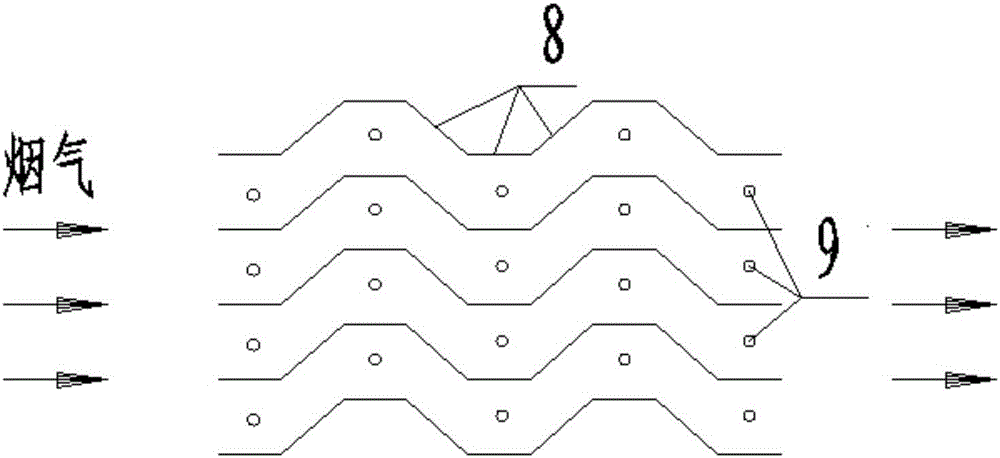

[0028] An anode plate, the surface of the anode plate is provided with at least one protrusion, and the protruding direction of the protrusion is perpendicular to or intersects with the direction of the flue gas flowing through the anode plate to form a set angle, so as to improve the turbulence of the flue gas; the flue gas passes through The protrusions on the protruding anode plate can effectively cause the turbulent flow of the flue gas, which is beneficial to the dispersion of the flue gas and contributes to the effect of dust removal on the flue gas.

[0029] The shape of the anode plate may be a continuous S-shape, and each protrusion may be in the shape of a trapezoid.

Embodiment 2

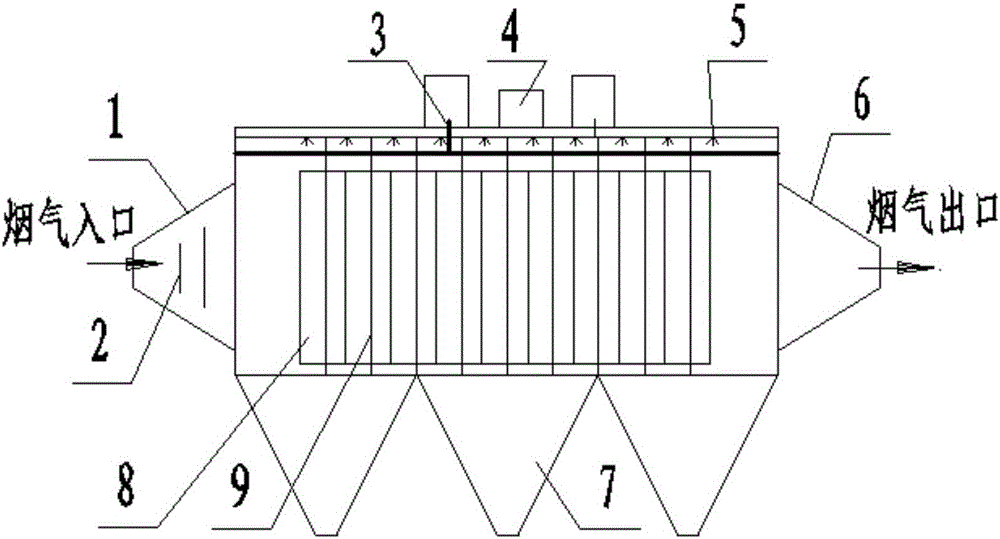

[0031] A wet electrostatic precipitator, comprising a housing, the housing is provided with a flue gas inlet 1 and a flue gas outlet 6, an air distribution device 2 is arranged at the flue gas inlet 1, an anode dust collection system 8 is arranged in the housing, and the anode collection The dust system 8 includes a plurality of anode plates set at intervals, and the surface of the anode plate is provided with at least one protrusion. When there are multiple protrusions on an anode plate, adjacent protrusions are separated by a set distance; The protruding direction is perpendicular to or intersects the direction of flue gas flowing through the anode plates to form a set angle to improve the turbulence of the flue gas. A cathode system 9 is arranged between every two adjacent anode plates; the flue gas enters the shell In the body, the flowing flue gas flows through the anode plate, and the turbulence of the flue gas is caused by the protrusions, which is conducive to the unifo...

Embodiment 3

[0042] The difference between this embodiment and embodiment 2 is:

[0043] Both the flue gas inlet and the flue gas outlet are arranged in a vertical position.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com