Electron beam welding tooling and welding process for aircraft cylinder body and wing

A technology of electron beam welding and aircraft tube, which is applied in electron beam welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of undiscovered wings and cylinders, and achieves a small degree of welding deformation, high energy conversion rate and time. the effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

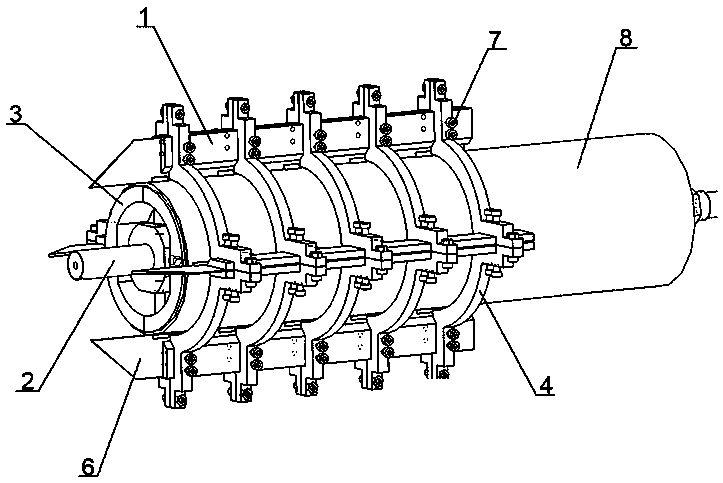

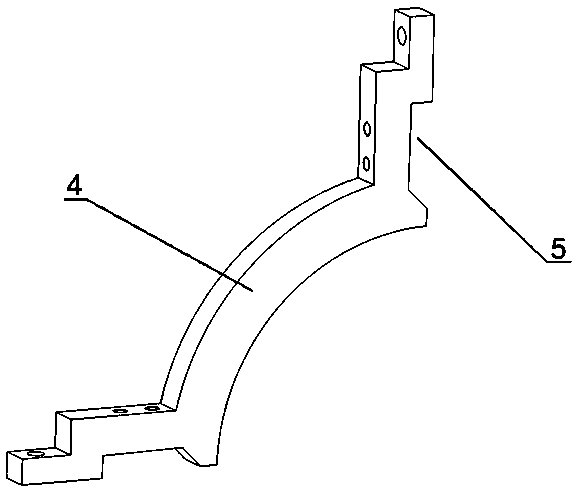

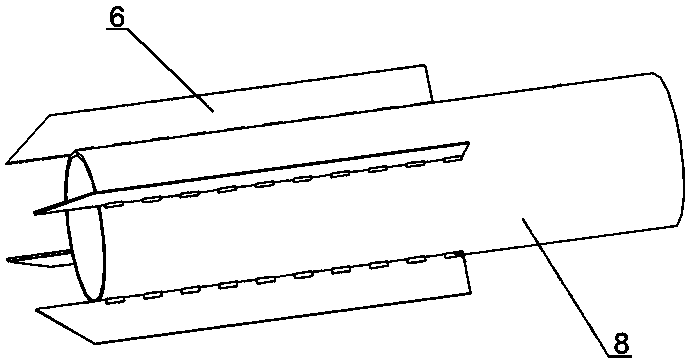

[0032] As shown in the figure: An electron beam welding tool for the aircraft barrel and wing, including five sets of ring clamps, backing plate 1, central shaft 2 and inner support disc 3, each set of ring clamps consists of four arc-shaped Clamps 4 are butted together, and four arc-shaped clamps 4 are connected end to end by bolts to form a ring-shaped clamp, and both end faces of arc-shaped clamps 4 are provided with grooves 5, and two adjacent arc-shaped clamps 4 After docking, a through hole for the wing 6 and the backing plate 1 clamping the wing 6 to pass through is formed, and the arc clamp 4 is connected with the corresponding backing plate 1 by an adjusting bolt 7. The central shaft 2 can The inner supporting disc 3 can be sleeved on the central shaft 2 and the outer peripheral surface of the inner supporting disc 3 is arranged against the inner wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com