Method for recycling sulfur dioxide in thionyl chloride production

A technology of sulfur dioxide and thionyl chloride, applied in chemical instruments and methods, inorganic chemistry, thionyl chloride, etc., can solve the problems of increased unit consumption of raw materials, increased investment, and reduced product yield, achieving simple operation and improved Utilization rate and product yield, the effect of small investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

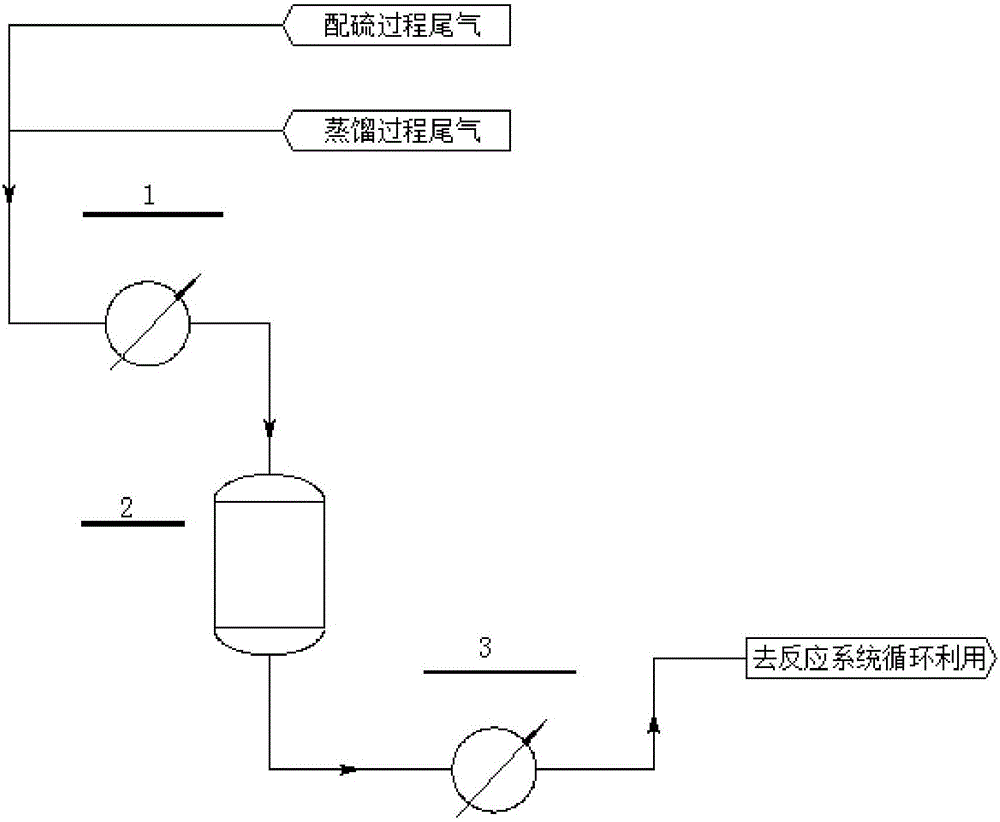

[0018] Such as figure 1 Shown, a method for reclaiming sulfur dioxide recycling in the production process of thionyl chloride comprises the following steps:

[0019] (1) The tail gas released from the sulfur oxychloride crude product into the crude product tank of the sulfur blending section, the sulfur blending kettle, and the separator, reflux tank, and finished product tank during the distillation process enters the tail gas condenser 1 for condensation, and the tail gas condenser 1 adopts - 20°C frozen brine is used as the refrigerant, and the recovery rate of sulfur dioxide reaches more than 90%;

[0020] (2) The sulfur dioxide gas in the tail gas is condensed into a liquid phase and enters the sulfur dioxide recovery tank 2, and a small amount of uncondensed tail gas enters the follow-up tail gas absorption system;

[0021] (3) The condensed sulfur dioxide liquid enters the sulfur dioxide vaporizer 3 and is gasified to slightly higher than the reaction system pressure (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com