Method for preparing Co3V2O8 with different morphologies by controlling hydrothermal time and Co3V2O8 with morphologies

A technology of heat time and water control, applied in chemical instruments and methods, inorganic chemistry, cobalt compounds, etc., to achieve the effect of strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Add ammonium metavanadate into deionized water at 70°C, and keep stirring for 5 minutes, the solution becomes light yellow-green;

[0050] (2) Add NaOH to the solution, and continue to stir for about 5 minutes until the solution becomes transparent and colorless;

[0051] (3) CoCl 2 ·6H 2 O was added to the above solution, and continued to stir for 10 minutes until the solution became transparent reddish brown, wherein the range of Co:V molar ratio was 1:3, and the concentration range of OHˉ was 0.03mol / L;

[0052] (4) Transfer the solution prepared above into a hydrothermal reaction kettle, and react at a temperature of 160° C., and the time range is 5min-16h;

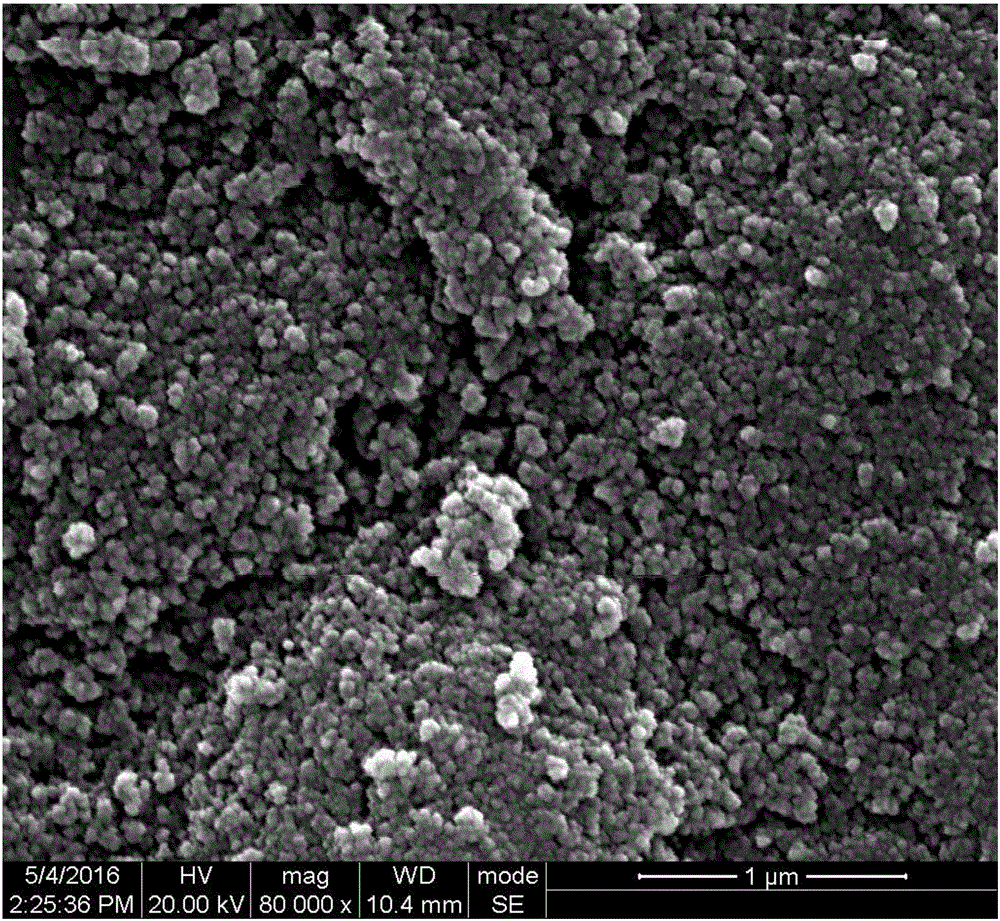

[0053] (5) Get the reaction sample whose reaction time is within 30min;

[0054] (6) Cool the above reaction sample to room temperature, wash it several times with deionized water and absolute ethanol, dry it at 60°C for 4 hours, put it into a tube furnace, calcinate it to 250°C, keep it for more than 2 ...

Embodiment 2

[0056] (1) Add ammonium metavanadate to deionized water at 80°C, and keep stirring for 10 minutes, the solution turns into light yellow-green;

[0057] (2) Add LiOH to the solution, and keep stirring for about 10 min until the solution becomes transparent and colorless;

[0058] (3) Co(NO 3 ) 2 ·6H 2 O was added to the above solution, and continued to stir for 10-15 minutes until the solution became transparent reddish brown, wherein the range of Co:V molar ratio was 1:5.5, and the concentration range of OHˉ was 0.035mol / L;

[0059] (4) transfer the solution prepared above into a hydrothermal reaction kettle, and react at a temperature of 220° C., and the time range is 5min-16h;

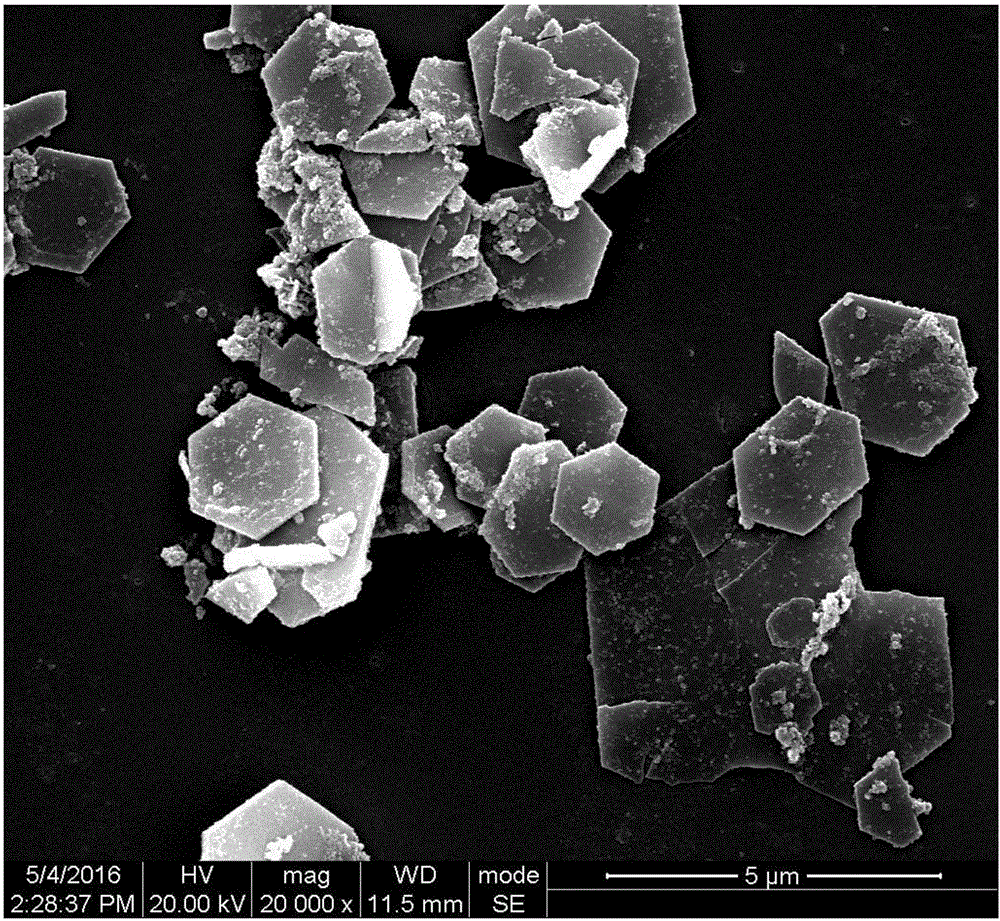

[0060] (5) get the reaction sample that the reaction time is 1-3h,

[0061] (6) Cool the above reaction sample to room temperature, wash it several times with deionized water and absolute ethanol, dry it at 90°C for 6h, put it into a tube furnace, calcinate it to 350°C, keep it for more than 2h, ...

Embodiment 3

[0063] (1) Add ammonium metavanadate into deionized water at 75°C, and keep stirring for 7 minutes, the solution turns light yellow-green;

[0064] (2) Add KOH to the solution, and continue stirring for about 8 minutes until the solution becomes transparent and colorless;

[0065] (3) Co(Ac) 2 4H 2 O was added to the above solution, and continued to stir for 12 minutes until the solution became transparent reddish brown, wherein the range of Co:V molar ratio was 1:4, and the concentration range of OHˉ was 0.032mol / L;

[0066] (4) Transfer the solution prepared above into a hydrothermal reaction kettle, and react at a temperature of 190° C., and the time range is 5min-16h;

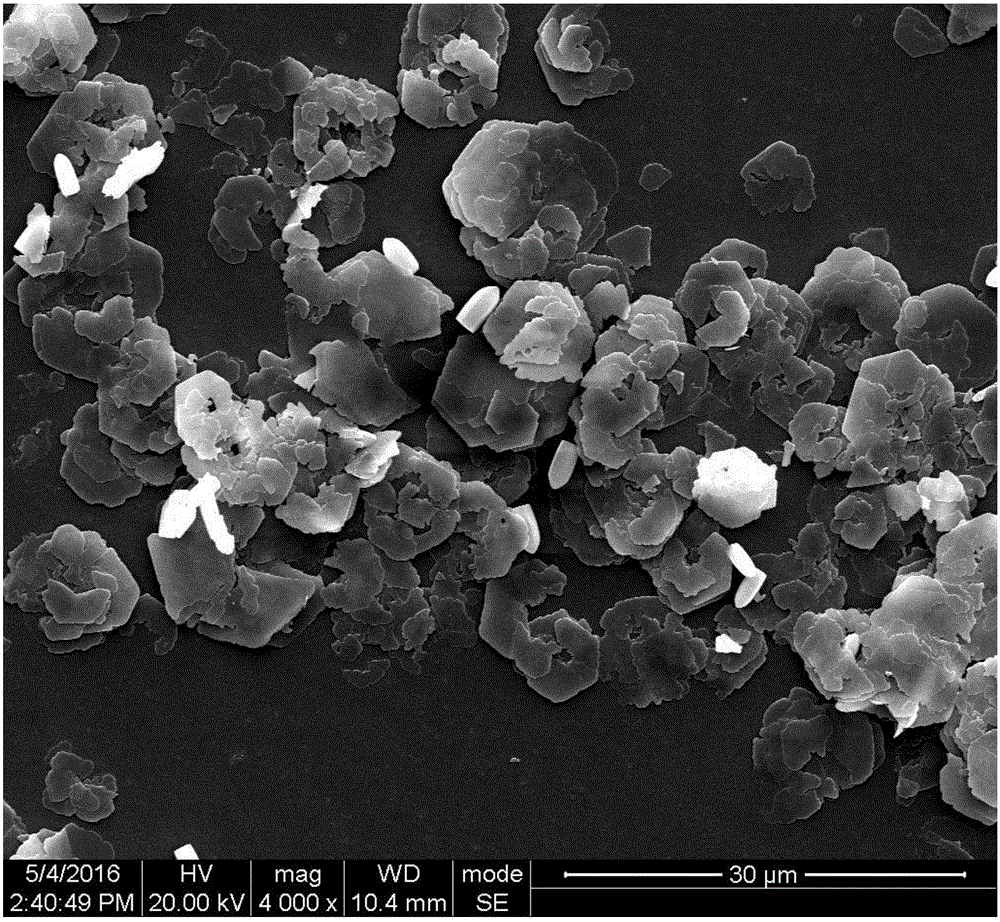

[0067] (5) getting reaction time is the reaction sample of 3-6h;

[0068] (6) Cool the above reaction sample to room temperature, wash it several times with deionized water and absolute ethanol, dry it at a temperature of 75°C for 5h, put it into a tube furnace, calcinate it to 300°C, keep it for more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com