Method for deep treatment of high-salinity industrial organic wastewater with plant composite bed

A technology for advanced treatment of organic sewage, applied in biological water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., to improve soil structure, prevent salinization, and increase soil fertility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

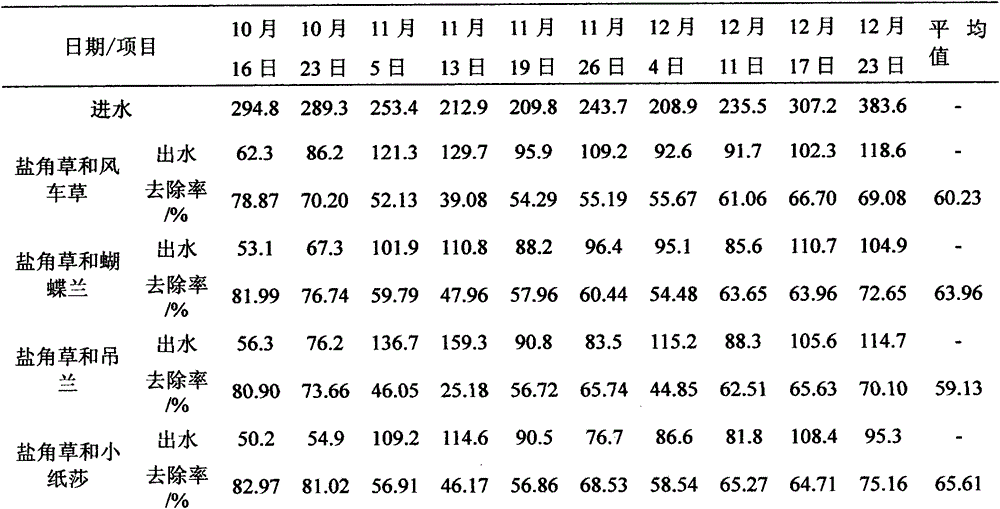

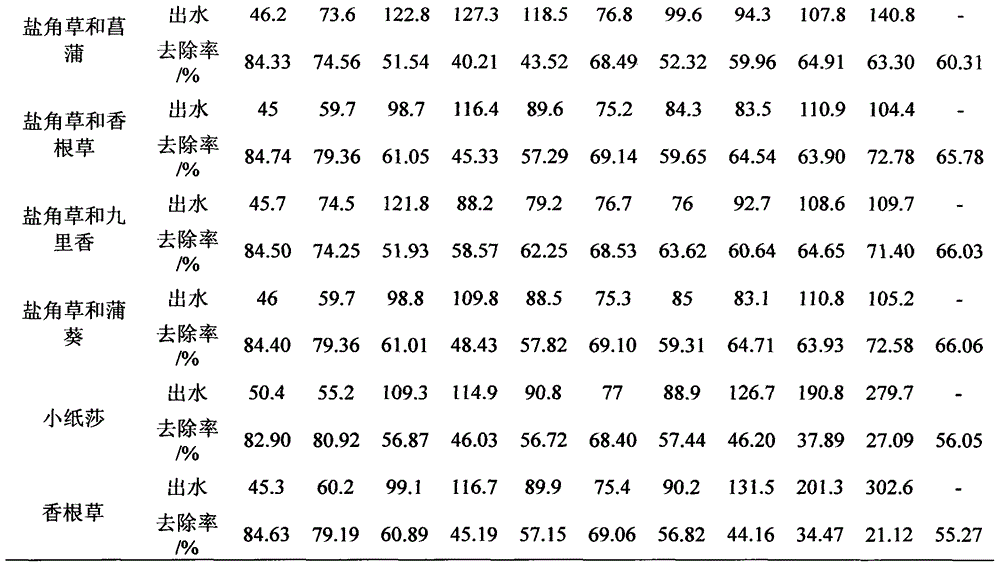

[0008] Embodiment 1: the comparative experiment of specific plant

[0009] Hongfengxing Chemical (Shenzhen) Co., Ltd. mainly uses the emulsion polymerization process to engage in the production of various water-based adhesives. During the production process, a small amount of high-concentration organic wastewater will be produced, and the main pollution index COD=5000~15000mg·L -1 , and BOD / COD-1 , and then add an appropriate amount of sodium chloride and sodium sulfate, so that the salt content in the waste water is 2% to 3%, and it is used as the influent of the plant composite bed.

[0010] Using 10 identical cylindrical containers (bottom area is 0.2m 2 ), put in gravel packing with a height of 60cm, and spread a layer of river sand under the packing for uniform water distribution. A water inlet pipe with a diameter of 2cm is set at a distance of 5cm above the filler. The water inlet pipe is connected to the nozzle, and there are holes with a diameter of 2.00mm on it. The...

Embodiment 2

[0017] Embodiment 2: application example of plant composite bed

[0018] Hubei Province Jingmen City Gurun Technology Co., Ltd. mainly produces ultraviolet photoinitiators, and the main pollution index of production wastewater COD=10000~20000mg·L -1 , the salt content is 2%~3%. After pretreatment, the main pollution index of wastewater COD=200~400mg·L -1 , and the salt content is 0.4% to 0.8%, which is used as the influent of the plant composite bed.

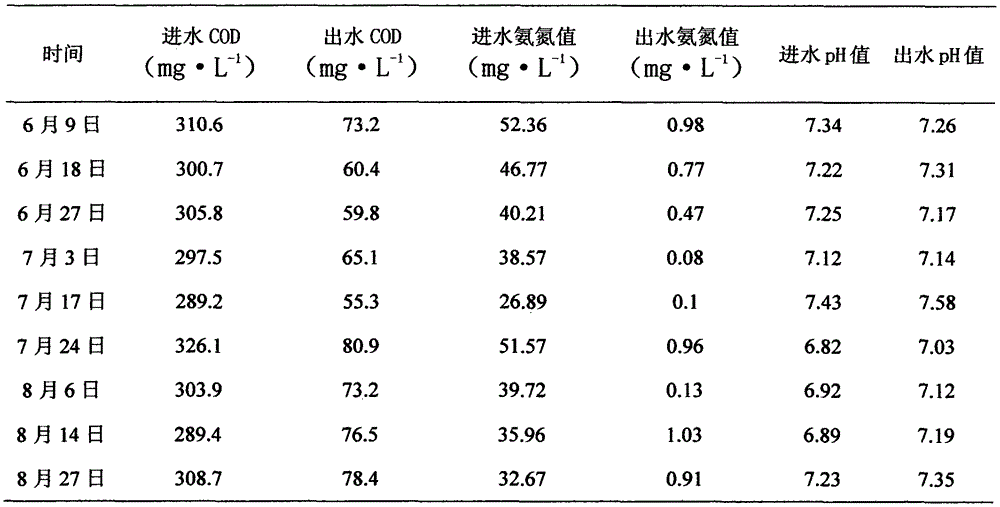

[0019] Table 2 Treatment effect table of plant composite bed

[0020]

[0021] The area of the plant compound bed of Jingmen Gurun Technology Co., Ltd. in Hubei Province is 500m 2 , the adsorption filler is activated carbon + river sand (volume ratio 1:1), and the planted plants are mixed interplanted plants of salicornia, mulberry, and palmetto, and the daily sewage treatment capacity is 75 tons. Table 2 records the measured data values of the company's plant compound bed in June, July, and August of 2014. From Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com