Self-heat-insulated lightweight-aggregate module

A lightweight aggregate, self-insulating technology, applied in the field of wall materials, can solve the problems of difficult construction, high energy consumption, heavy pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0027] Specific implementation method 1: The self-insulating lightweight aggregate module in this embodiment is composed of A: one or more of lightweight aggregate, ceramsite or scouring sand, B: stone material, C: cement and D: foam According to each cubic meter, A accounts for 60-100% of the volume of the module, B accounts for 0-40% of the volume of the module, the amount of C is 100-150Kg, and the amount of D is 100-1000g.

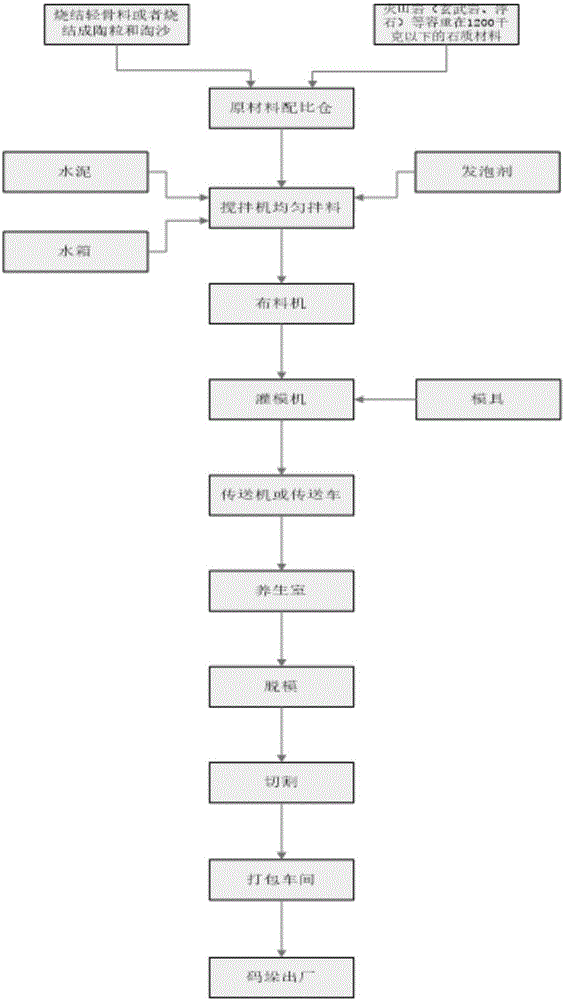

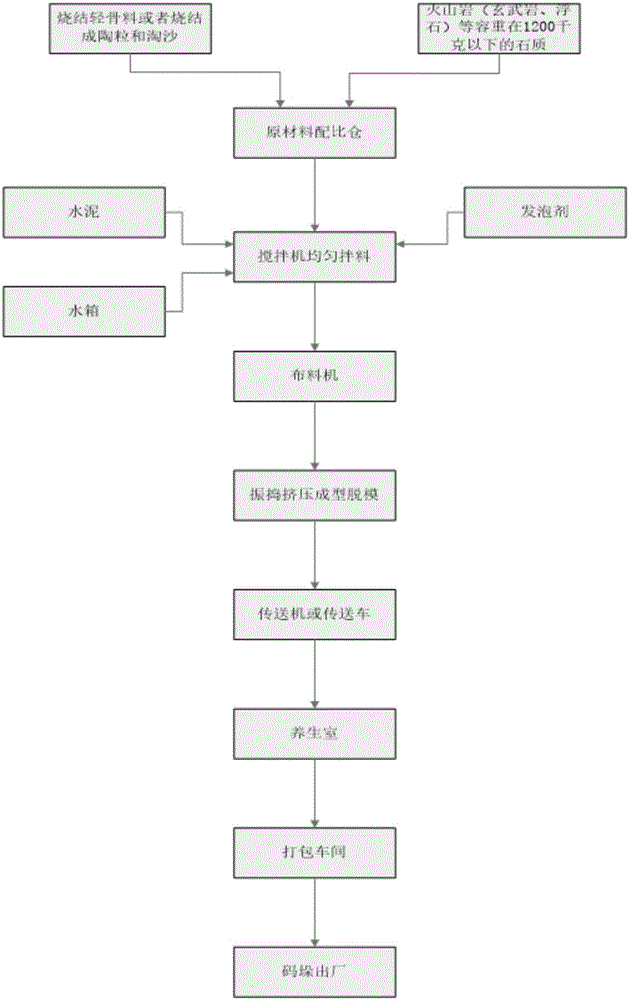

[0028] like figure 1 As shown, the specific preparation steps of the self-insulating lightweight aggregate module in this embodiment are as follows:

[0029] According to the proportion of raw materials, add cement and foaming agent for forced mixing, mold pouring molding or demoulding cutting molding, without extrusion, so that the density of the product is relatively reduced, and the weight of the produced product is less than 900 kg. This molding method Most of the products are mainly filling walls, and the specifications can be adjusted and cut ac...

specific Embodiment approach 2

[0035] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the self-insulating lightweight aggregate module is composed of A: one or more of lightweight aggregate, ceramsite or scouring sand, C: cement and D: hair Foaming agent is prepared.

specific Embodiment approach 3

[0036] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 is that the self-insulating lightweight aggregate module is composed of A: one or more of lightweight aggregate, ceramsite or scouring sand, B: stone material, C : cement and D: foaming agent, the A accounts for 60-90% of the volume of the module, and B accounts for 10-40% of the volume of the module.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| drying shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com