A method for eliminating and suppressing hydrogen sulfide in oil well production process

A production process, hydrogen sulfide technology, applied in the direction of earthwork drilling, wellbore/well components, etc., can solve the problems that cannot fully meet the oilfield production, have no good treatment methods, and affect the normal production of the oilfield, and achieve good economic benefits. Inhibit and eliminate the production of hydrogen sulfide and avoid the effect of frequent alkali flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

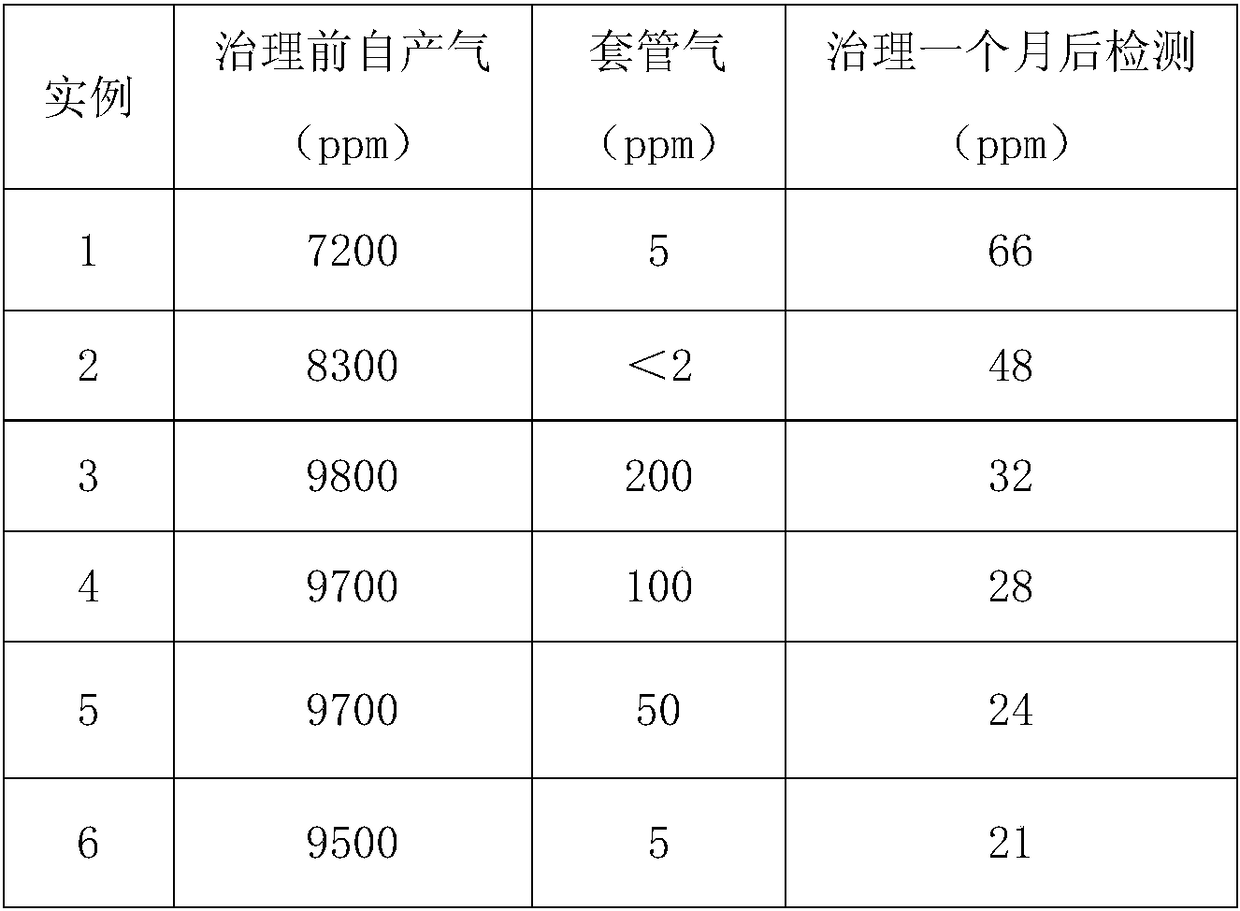

Embodiment 1

[0037] The hydrogen sulfide output concentration of the oil well before the measures was 7200ppm;

[0038] Biological inhibitor: get dodecyl dimethyl benzyl ammonium chloride and dissolve it in water;

[0039] The treatment measures for the water well string and the water injection zone near the well include the following steps:

[0040] (1) The dodecyldimethylbenzylammonium chloride mass concentration is 1% dodecyldimethylbenzylammonium chloride bio-inhibitor filling to formation near wellbore zone 2m;

[0041] (2) the dodecyl dimethyl benzyl ammonium chloride mass concentration is 5% dodecyl dimethyl benzyl ammonium chloride bio-inhibitor is filled with the whole shaft of the water well;

[0042] (3) close the well and react for 24 hours;

[0043] (4) Periodically inject dodecyl dimethyl benzyl ammonium chloride bioinhibitor into the entire wellbore of the water well; when the water injection front advances to the oil well, if the hydrogen sulfide concentration produced by...

Embodiment 2

[0060] The hydrogen sulfide output concentration of the oil well before the measures was 7200ppm;

[0061] Biological inhibitor: get dodecyl dimethyl benzyl ammonium chloride and dissolve it in water;

[0062] The treatment measures for the water well string and the water injection zone near the well include the following steps:

[0063] (1) Dodecyldimethylbenzylammonium chloride mass concentration is 10% dodecyldimethylbenzylammonium chloride bio-inhibitor filling to formation near wellbore zone 2m;

[0064] (2) the dodecyl dimethyl benzyl ammonium chloride mass concentration is 1% dodecyl dimethyl benzyl ammonium chloride bio-inhibitor and fills the whole shaft of the water well;

[0065] (3) close the well and react for 48 hours;

[0066] (4) Periodically inject dodecyl dimethyl benzyl ammonium chloride bioinhibitor into the entire wellbore of the water well; when the water injection front advances to the oil well, if the hydrogen sulfide concentration produced by the oil...

Embodiment 3

[0083] The hydrogen sulfide output concentration of the oil well before the measures was 7200ppm;

[0084] Biological inhibitor: get dodecyl dimethyl benzyl ammonium chloride and dissolve it in water;

[0085] The treatment measures for the water well string and the water injection zone near the well include the following steps:

[0086] (1) Dodecyldimethylbenzylammonium chloride mass concentration is 5% dodecyldimethylbenzylammonium chloride bio-inhibitor filling to formation near wellbore zone 2m;

[0087] (2) the dodecyl dimethyl benzyl ammonium chloride mass concentration is 3% dodecyl dimethyl benzyl ammonium chloride bio-inhibitor and fills the whole shaft of the water well;

[0088] (3) close the well and react for 36 hours;

[0089] (4) Periodically inject dodecyl dimethyl benzyl ammonium chloride bioinhibitor into the entire wellbore of the water well; when the water injection front advances to the oil well, if the hydrogen sulfide concentration produced by the oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com