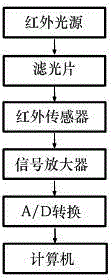

Real-time monitoring method in metal friction wear self-repair process

A friction and wear, real-time monitoring technology, applied in electrical radiation detectors and other directions, can solve the problems of immaturity, large errors, and sensitivity of vibration and noise detection to the external environment, achieving long-term measurement and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

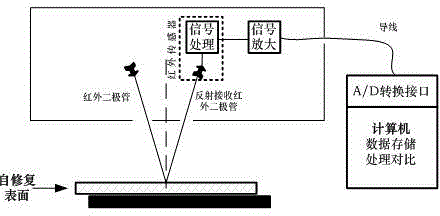

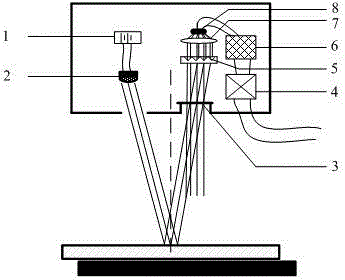

[0019] The present invention proposes a new detection method for detecting surface self-repair effects. The following takes the self-repair of the surface of the ring slider as an example and introduces the present invention in detail in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only It is used to explain the present invention, not to limit the present invention. The specific method is as follows.

[0020] 1. The infrared light source adopts IR12-21C diode, the receiver adopts P3207-08 lead selenide photoconductive sensor, and the measuring head is about 10cm away from the surface. The laser diode is driven by a drive circuit composed of OPA2662, and the bias current circuit is provided by OPA602 and triode 2N3906 to provide bias current for the laser diode. The infrared probe is shown in the figure: 1, 2 are independent infrared light sources, and 2 is an infrared light-emitting diode. The infrared l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com