Optimization design method of composite material wing panel

A composite material and optimization design technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as material performance and aircraft weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

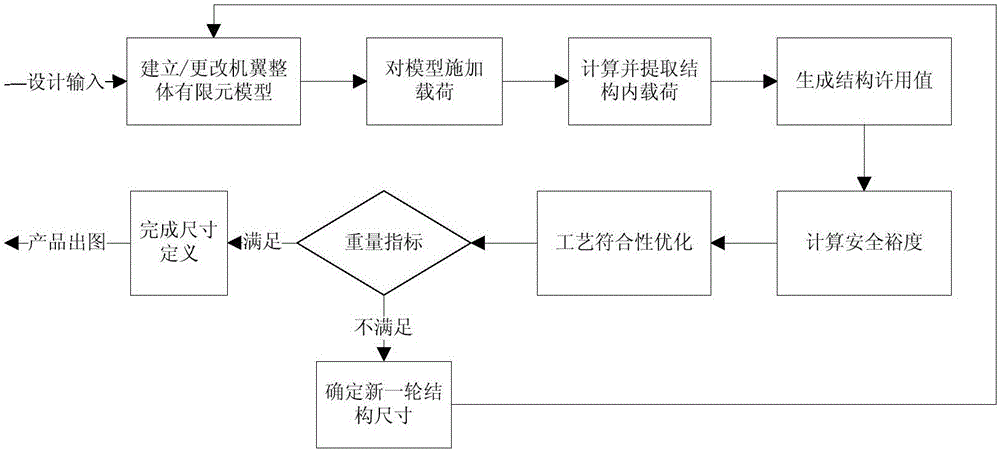

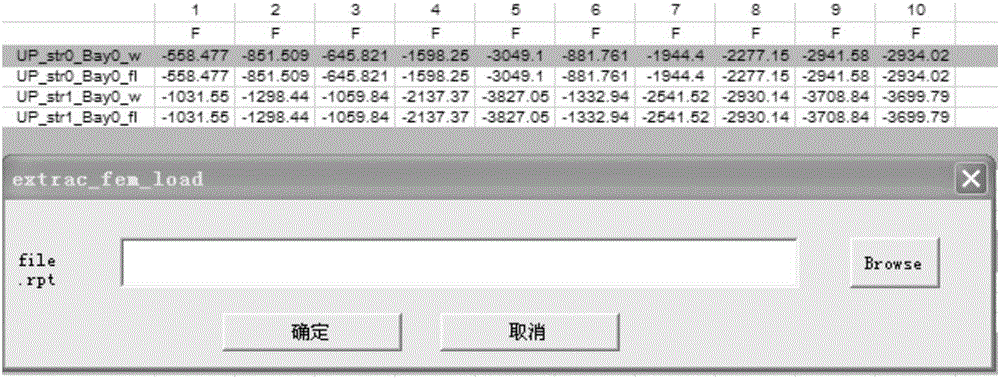

[0118] The present invention is described in detail below in conjunction with the accompanying drawings, and the whole optimal design method is integrated in the flow chart in the appendix figure 1 . The specific process of its implementation is as follows:

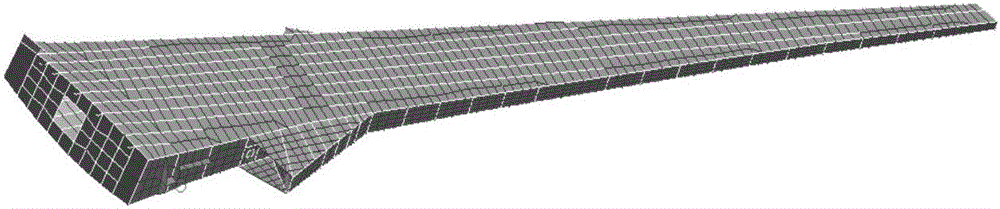

[0119] Step 1: Establish the finite element model of the wing structure, see attached figure 2 . Determine the modeling criteria as follows:

[0120] A. Considering that the front and rear beams, ribs and important connecting structures of the aircraft wing in actual service and the upper and lower panels participate in the load transfer of the entire wing structure and interact with each other, the finite element model for analysis adopts the overall box-section structure of the wing ;

[0121] B. Make sure that the overall finite element modeling coordinate system is consistent with the model aircraft coordinate system definition;

[0122] C. In order to ensure the uniqueness of the unit and to easily find the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com