Annealing crystallization process for zero-sequence transformer

A zero-sequence transformer and crystallization technology, which is applied in the manufacture of inductors/transformers/magnets, manufacturing tools, furnace types, etc., can solve problems such as high manufacturing costs, expensive prices, and complex processing, and achieve good market effects and consistency Good, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

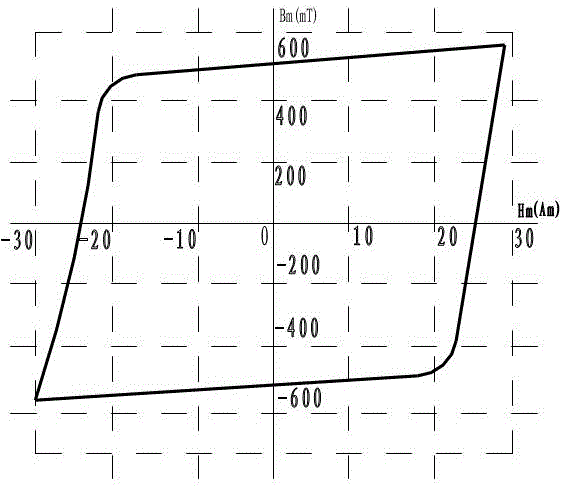

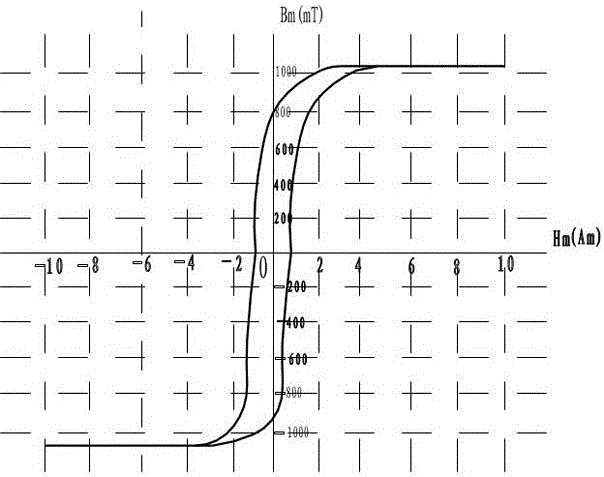

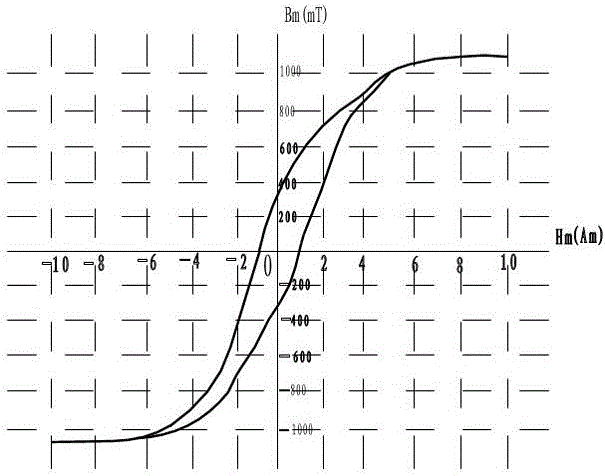

[0009] Iron-based nanocrystalline alloys are composed of iron, silicon, boron, and a small amount of copper, molybdenum, and niobium, among which copper and niobium are essential elements for obtaining nanocrystalline structures. They are first made into amorphous strips and then properly annealed to form a mixed structure of microcrystalline and amorphous. Although this material is cheap, it has excellent magnetic properties and is almost comparable to the best cobalt-based amorphous alloy in amorphous alloys, but it does not contain expensive cobalt. The ideal material is also the replacement product of permalloy and ferrite. The present invention utilizes the advantages of the above-mentioned iron-based nanocrystals and obtains a special transformer magnetic core suitable for European leakage plugs through special processing techniques. Take the soft magnetic material MATS-2010S as an example.

[0010] A zero-sequence transformer core annealing and crystallization process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com