De-edged super back seal layer structure for silicon wafer and manufacturing method thereof

A layer structure, silicon wafer technology, applied in semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, semiconductor devices, etc., can solve problems such as pyramids, particle pollution, edge stacking faults, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The structure of the super back-sealing layer with edge removal and its manufacturing method for silicon wafers according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

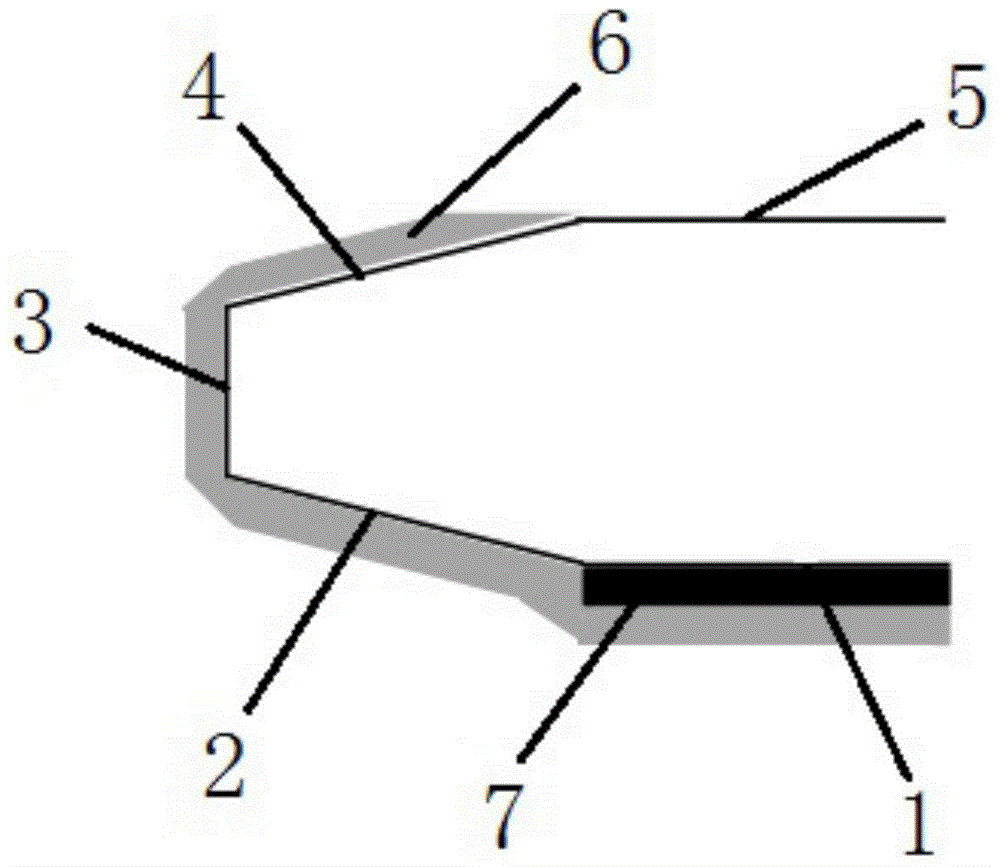

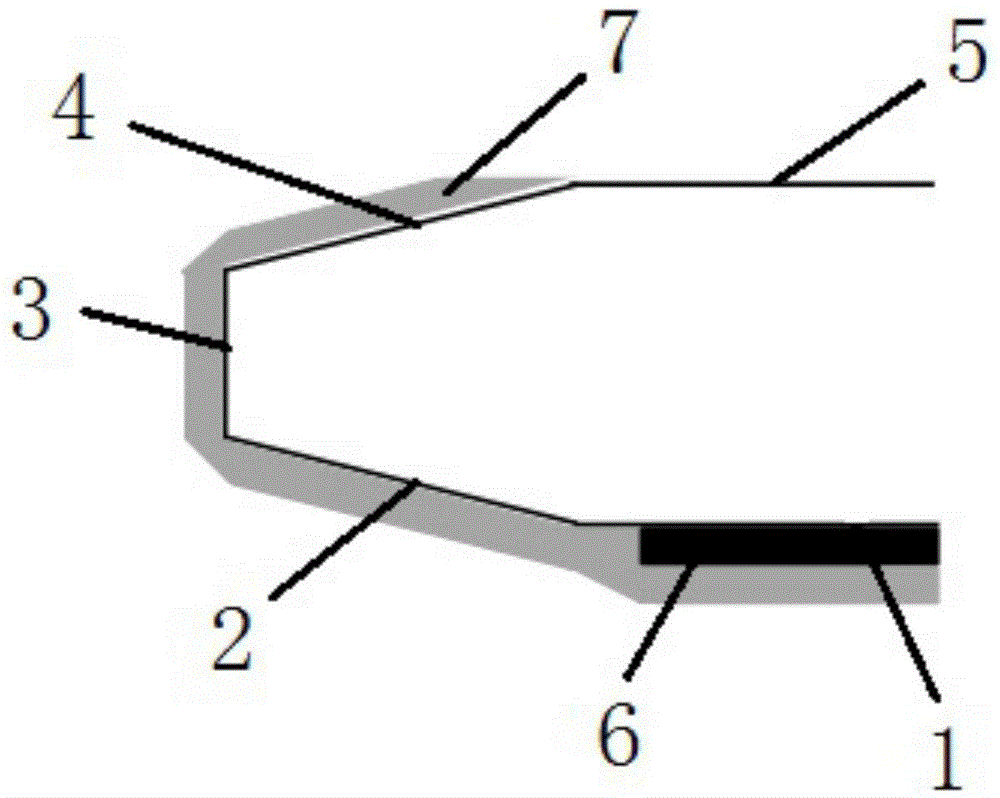

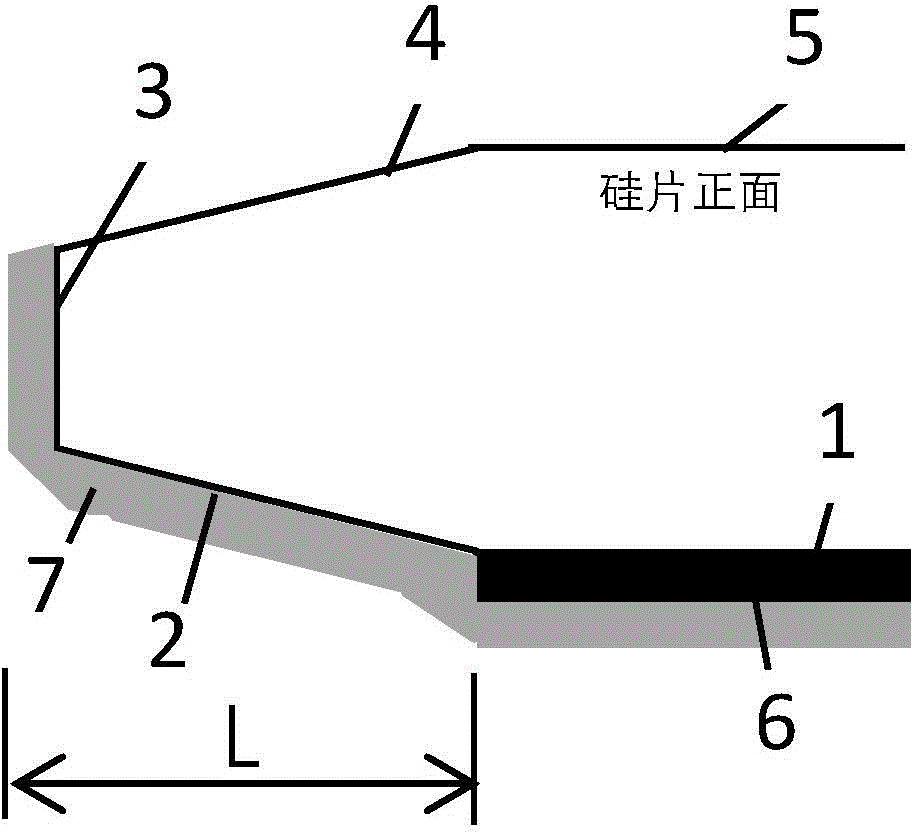

[0019] Such as image 3 , Figure 4 As shown, the present invention is used for silicon wafers with a super back-sealing layer structure with edge removal. The back-sealing layer is completely covered on the back side 1, the back bevel area 2, and the edge area 3 of the silicon wafer, so as to maximize the back-sealing effect. The front side 5 of the silicon wafer is the polishing surface. The bevel region 4 on the front side of the silicon wafer is a smooth monocrystalline silicon surface without polycrystalline silicon film coverage. The silicon dioxide back-sealing layer 6 covers the back side 1 of the silicon wafer, and the polysilicon back-sealing layer 7 covers the outer side of the silicon dioxide back-sealing layer 6 , coveri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com