Prefabricated sandwich-type thermal-insulation wallboard, and preparing method thereof

A thermal insulation wallboard and sandwich-type technology, which is applied to chemical instruments and methods, manufacturing tools, building components, etc., can solve the problems of large weight and poor thermal performance of external wallboards, achieve small self-weight, improve thermal performance, Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

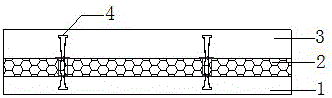

[0061] like figure 1 As shown, the prefabricated sandwich-type sandwich insulation wallboard includes three layers, namely a decorative protection layer 1, an insulation layer 2 and a structural layer 3, and the three layers are connected into a whole through a shear bond 4. The decorative protection layer 1 is made of CL25 ceramsite concrete with a thickness of 50mm; the insulation layer 2 is made of EPS board with a thickness of 50mm; the structural layer 3 is made of C30 concrete with a thickness of 80mm. The shear key 4 is selected from a shear key with superior mechanical and thermal properties, and the depth embedded in the decorative protective layer 1 is 35 mm, and the depth embedded in the structural layer 3 is 65 mm.

[0062] When making wall panels, first build the formwork, clean the surface, apply the release agent and place the decorative protective layer 1 steel mesh, then pour the ceramsite concrete; then vibrate the decorative protective layer 1 ceramsite conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com