Enzymatic hydrolysis method of citrus pulp

A technology of citrus residue and enzymolysis, applied in application, animal feed, animal feed, etc., can solve the problems of restricting the release of nutrients, unfavorable digestion and absorption of animals, etc., and achieves increased feeding value, obvious changes in nutrients, and fiber structure. Significant change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] An enzymatic hydrolysis method of citrus pomace, the method steps are as follows:

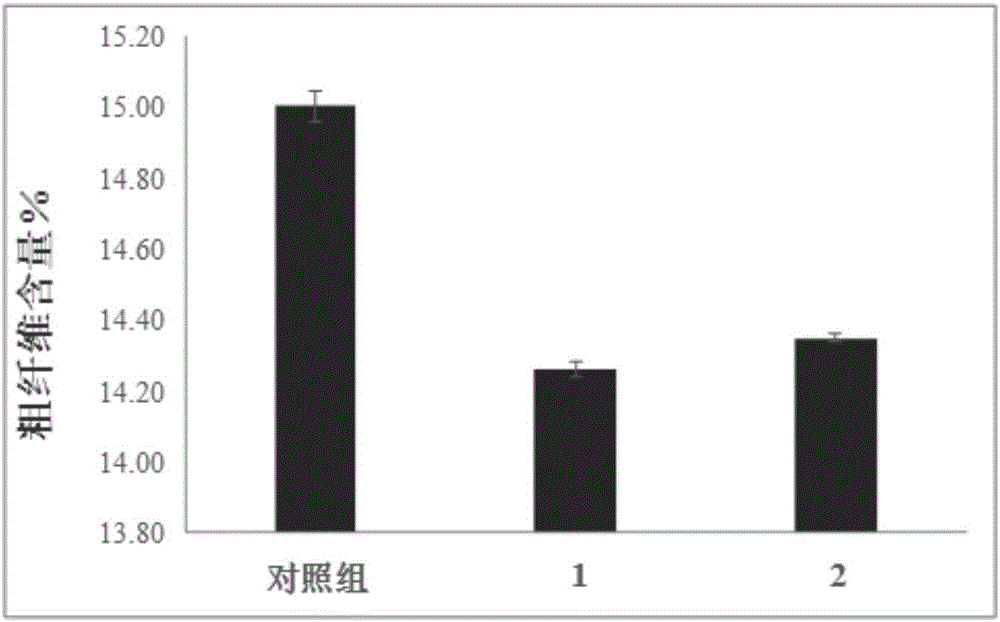

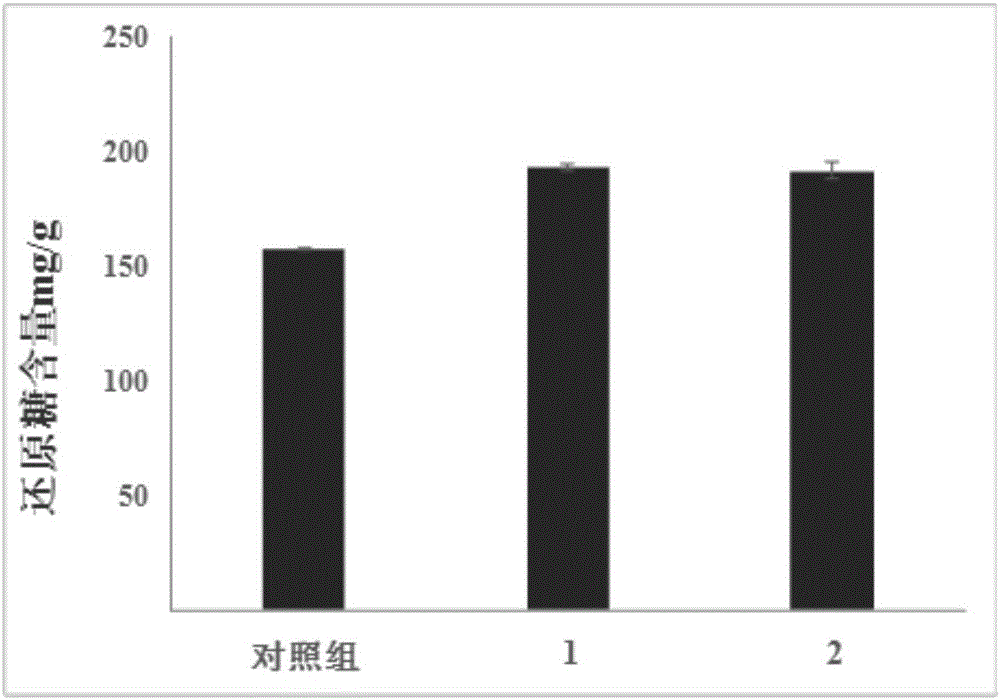

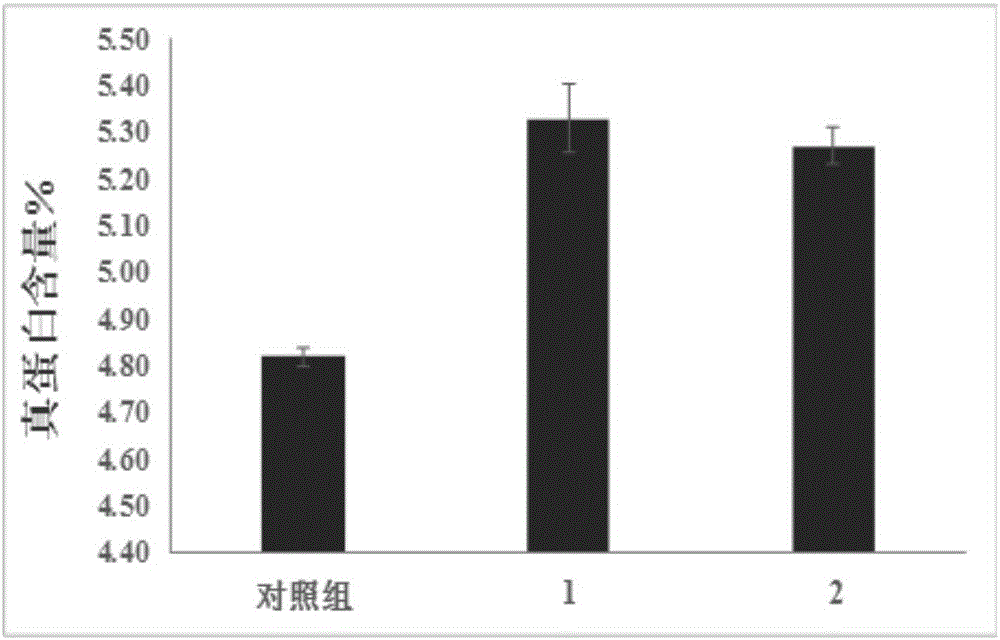

[0025] Dry the citrus residues and crush them, pass through a 20-mesh sieve, take an appropriate amount of citrus residues and sterilize them in an autoclave at 121°C for 30 minutes, and fill the sterile citrus residues into 150mL conical flasks as an enzymatic hydrolysis matrix. Weigh 30g, add sterile water at a ratio of 1:1.5 (m / v), mix, and then add 0.2% combined enzyme solution, mix well, seal the Erlenmeyer flask and place it in a constant temperature water bath Carry out enzymolysis reaction in the medium, enzymolysis 18-24h under the condition of temperature of 30~50℃, lyophilize, rehydrate for 24h, pulverize, measure true protein, crude fiber, total reducing sugar content. The composition of the combined enzyme liquid is: pectinase + cellulase + glucanase, the mass ratio of the three is 2:1:1.

Embodiment 2

[0027] An enzymatic hydrolysis method of citrus pomace, the method steps are as follows:

[0028] Dry the citrus residues and crush them, pass through a 20-mesh sieve, take an appropriate amount of citrus residues and sterilize them in an autoclave at 121°C for 30 minutes, and fill the sterile citrus residues into 150mL conical flasks as an enzymatic hydrolysis matrix. Weigh 30g, add sterile water at a ratio of 1:1.5 (m / v), mix, and then add 0.2% combined enzyme solution, mix well, seal the Erlenmeyer flask and place it in a constant temperature water bath Carry out enzymolysis reaction in the medium, enzymolysis 18-24h under the condition of temperature of 30~50℃, lyophilize, rehydrate for 24h, pulverize, measure true protein, crude fiber, total reducing sugar content. The composition of the combined enzyme liquid is: pectinase + cellulase + mannanase, the mass ratio of the three is 2:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com