Maca flower superfine powder and preparation method thereof

A technology of maca flower and superfine powder, which is applied in powder transportation, pharmaceutical formulations, medical preparations containing active ingredients, etc. It can solve the problems of low biomass, extensive process, and high labor cost for picking, so as to achieve uniform powder quality, The preparation process is simple and easy, and the effect of improving the drug effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

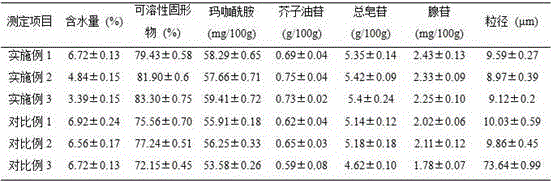

Embodiment 1

[0026] A kind of maca flower superfine powder, adopts following method to prepare:

[0027] S1. Drying: Pre-freeze maca flowers in -20°C refrigerator for 12 hours, then transfer to a vacuum freeze dryer for drying, set the shelf temperature program: the first stage of drying at 25°C for 10 hours; the second stage of drying at 30°C 20 h; the third stage was dried at 35°C for 5 h; the fourth stage was dried at 25°C for 3 h; the water content of dried maca flowers was 6.72 %;

[0028] S2. Coarse pulverization: Put the dried maca flowers into a universal pulverizer, pulverize them at 20,000 r / min for 10 s, and grind them into coarse powder, and place them at a low temperature of 0°C;

[0029] S3. Superfine pulverization: the above-mentioned coarse powder and the air with a temperature of 0° C. after freeze-drying are injected into the superfine pulverizer together, and the maca flower cells are broken by low-temperature wall-breaking technology to obtain the superfine powder of ma...

Embodiment 2

[0032] A kind of maca flower superfine powder, adopts following method to prepare:

[0033] S1. Drying: Pre-freeze maca flowers in -20°C refrigerator for 18 hours, then transfer to a vacuum freeze dryer for drying, set the shelf temperature program: the first stage of drying at 25°C for 13 hours; the second stage of drying at 30°C 22 h; the third stage was dried at 35°C for 8 h; the fourth stage was dried at 25°C for 4 h; the water content of dried maca flowers was 4.84 %;

[0034] S2. Coarse pulverization: Put the dried maca flowers into a universal pulverizer, pulverize them at 23000 r / min for 20 s and grind them into coarse powder, and place them at a low temperature of 10°C;

[0035] S3. Superfine pulverization: the above-mentioned coarse powder and air at a temperature of 10° C. after freeze-drying are injected into a superfine pulverizer together, and a low-temperature wall-breaking technology is used to break the wall of Maca flower cells to obtain Maca flower superfine...

Embodiment 3

[0038] A kind of maca flower superfine powder, adopts following method to prepare:

[0039] S1. Drying: Pre-freeze maca flowers in -20°C refrigerator for 24 hours, then transfer to a vacuum freeze dryer for drying, set the shelf temperature program: the first stage of drying at 25°C for 15 hours; the second stage of drying at 30°C 25 h; the third stage was dried at 35°C for 10 h; the fourth stage was dried at 25°C for 5 h; the water content of dried maca flowers was 3.39 %;

[0040] S2. Coarse pulverization: Put the dried maca flowers into a universal pulverizer, pulverize them at 25,000 r / min for 30 s, and grind them into coarse powder, and place them at a low temperature of 15°C;

[0041] S3. Superfine pulverization: the above-mentioned coarse powder and air at a temperature of 20° C. after freeze-drying are injected into a superfine pulverizer together, and a low-temperature wall-breaking technology is used to break the wall of maca flower cells to obtain superfine maca flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com