Preparation method of layer-by-layer self-assembly metal-organic framework composite film

A metal-organic framework, layer-by-layer self-assembly technology, applied in the field of water treatment, can solve problems such as poor compatibility, many impurities, and non-adjustable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

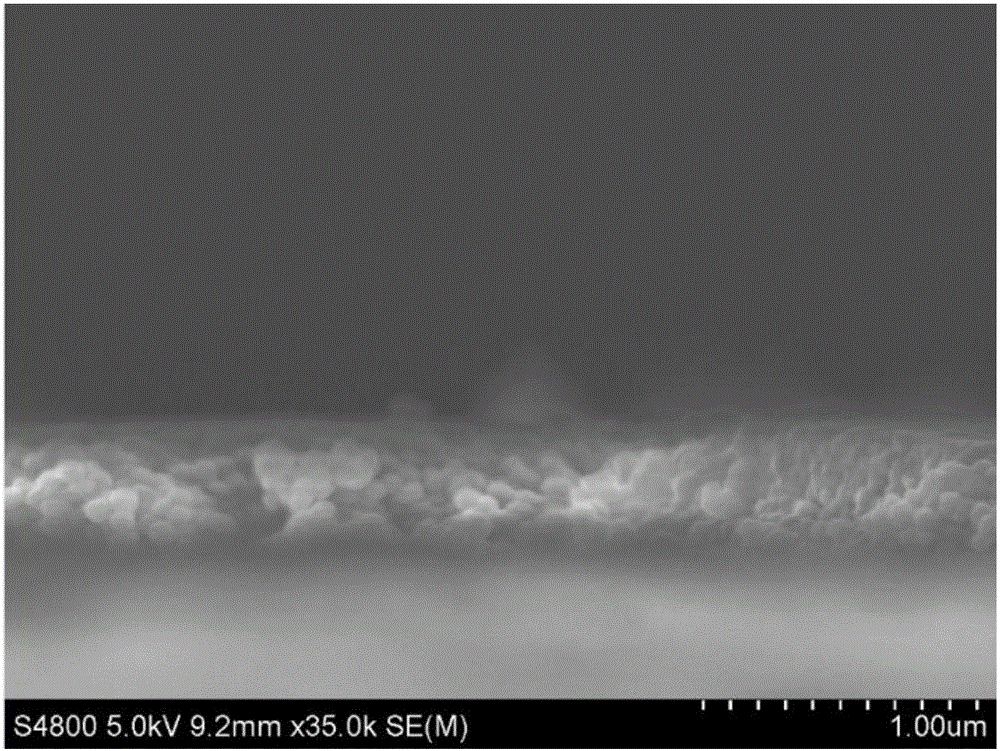

[0006] Technical scheme of the present invention is as follows:

[0007] A method for preparing a layer-by-layer self-assembled metal-organic framework composite film, comprising the following steps:

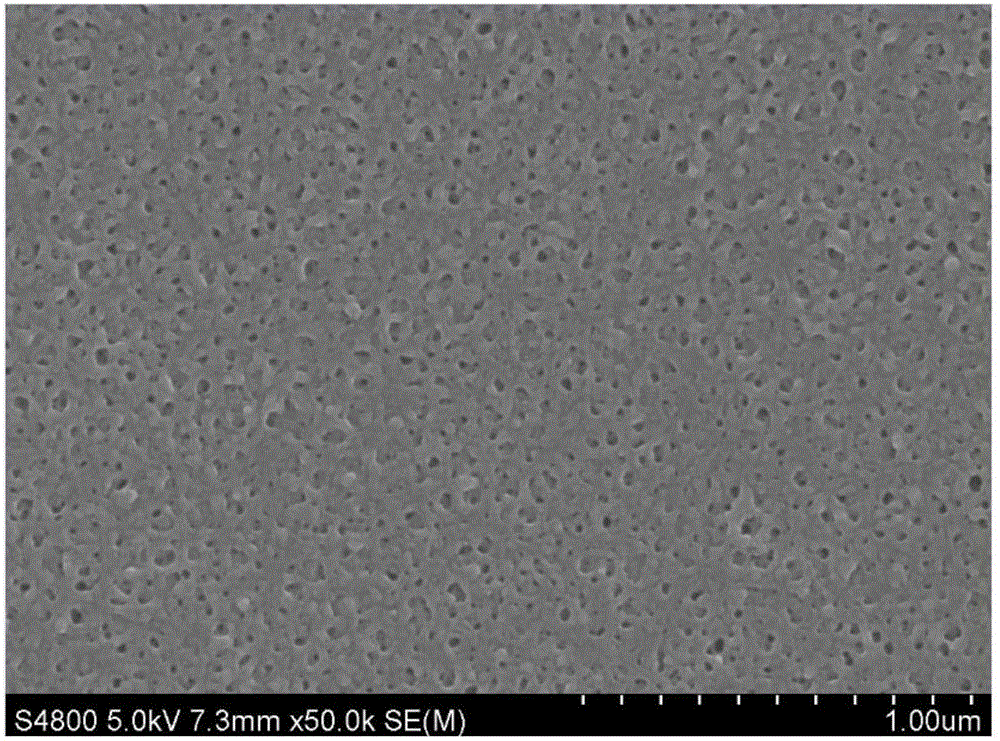

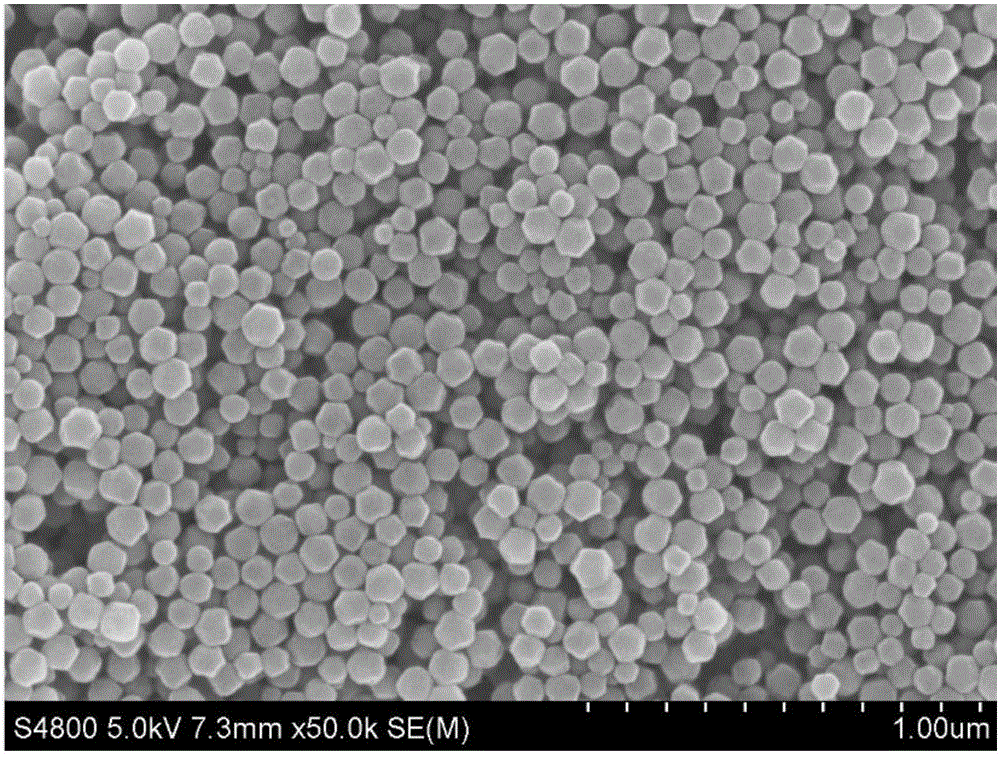

[0008] (1) Synthesis of ZIF-8

[0009] 1) Zn(NO 3 ) 2 ·6H 2 O dissolved in methanol, Zn(NO 3 ) 2 ·6H 2 The mass volume ratio of O to methanol is: (0.6-1.0): 50, unit g / mL; the methanol solution of zinc nitrate is obtained,

[0010] 2) Dissolving 2-methylimidazole in methanol, the mass volume ratio of methylimidazole to methanol is: (0.6-1.0):50, unit g / mL; to obtain a methanol solution of methylimidazole;

[0011] 3) Pour the methanol solution of methylimidazole obtained in step 2) into the methanol solution of zinc nitrate, the volume ratio of the methanol solution of methylimidazole and the methanol solution of zinc nitrate is (1-2:(1-2) ), let stand for 24-36h, the precipitate is centrifuged, washed, dried and recovered under vacuum, then dissolved in methanol to form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com